How To Torque Crankshaft Pulley Bolt

The crankshaft pulley bolt, often the unsung hero of your engine's accessory drive, plays a critical role in transferring power from the crankshaft to components like the alternator, power steering pump, and air conditioning compressor. But replacing it, often required when replacing a timing belt or performing other front-end engine maintenance, can be a surprisingly challenging task. The sheer torque required to properly tighten this bolt – sometimes exceeding hundreds of foot-pounds – makes it a job where understanding the "why" is just as important as the "how." So, what’s the secret behind achieving the correct torque on that stubborn crankshaft pulley bolt, and why is it so crucial?

The Crankshaft Pulley Bolt Challenge: Why Torque Matters

Imagine trying to secure a spinning top to a table. If you don't apply enough force, the top will wobble and eventually fly off. The crankshaft pulley bolt faces a similar challenge. It needs to withstand the immense torsional forces generated by the engine's combustion process. This means that the bolt must be tightened to a precise specification to ensure a secure and reliable connection between the crankshaft and the pulley.

Under-torquing the bolt is a recipe for disaster. It can lead to the pulley loosening over time, causing vibration, noise, and ultimately, damage to the crankshaft and other engine components. In the worst-case scenario, a loose pulley can sheer the bolt, leading to catastrophic engine failure. On the other hand, over-torquing the bolt can also be detrimental. Excessive force can stretch or weaken the bolt, making it prone to failure or damaging the threads in the crankshaft. This is why simply "winging it" with an impact wrench is a risky proposition.

Mechanical Breakdown: How the Crankshaft Pulley Bolt Works

To understand why precise torque is so important, let's delve into the mechanics of the crankshaft pulley bolt. The bolt itself is typically a high-strength fastener, designed to withstand significant tensile loads. When tightened, the bolt stretches slightly, creating a clamping force between the pulley and the crankshaft. This clamping force is what prevents the pulley from slipping or rotating independently of the crankshaft.

Think of it like a vise holding a piece of wood. The vise applies pressure to the wood, keeping it securely in place. The crankshaft pulley bolt acts in a similar way, using clamping force to secure the pulley to the crankshaft. The amount of clamping force is directly proportional to the torque applied to the bolt. A torque wrench allows you to measure and control this force, ensuring that it falls within the manufacturer's specified range.

Many crankshaft pulley bolts are designed to be tightened using a torque-to-yield (TTY) method. TTY bolts are designed to stretch slightly beyond their elastic limit when tightened. This allows them to maintain a more consistent clamping force over time, even as the engine heats up and cools down. TTY bolts are typically tightened to a specific torque value, followed by an additional angle of rotation (e.g., 90 degrees or 180 degrees). This ensures that the bolt is stretched to the correct point.

Pros and Cons of TTY Bolts

Pros:

- More consistent clamping force over time.

- Reduced risk of loosening due to thermal expansion and contraction.

Cons:

- TTY bolts must be replaced after each use, as they are permanently deformed during tightening.

- More complex tightening procedure requiring an angle gauge or electronic torque wrench.

Not all crankshaft pulley bolts are TTY. Some use a traditional torque specification. It's crucial to consult the manufacturer's service manual for the correct tightening procedure and torque value for your specific vehicle.

The Torqueing Process: A Step-by-Step Guide

While specific procedures vary by vehicle, here’s a general approach for tightening a crankshaft pulley bolt:

- Gather Your Tools and Information: You'll need a calibrated torque wrench, the correct socket for the bolt, a breaker bar (for initial loosening and final tightening), a crankshaft holding tool (more on this below), and the vehicle's service manual.

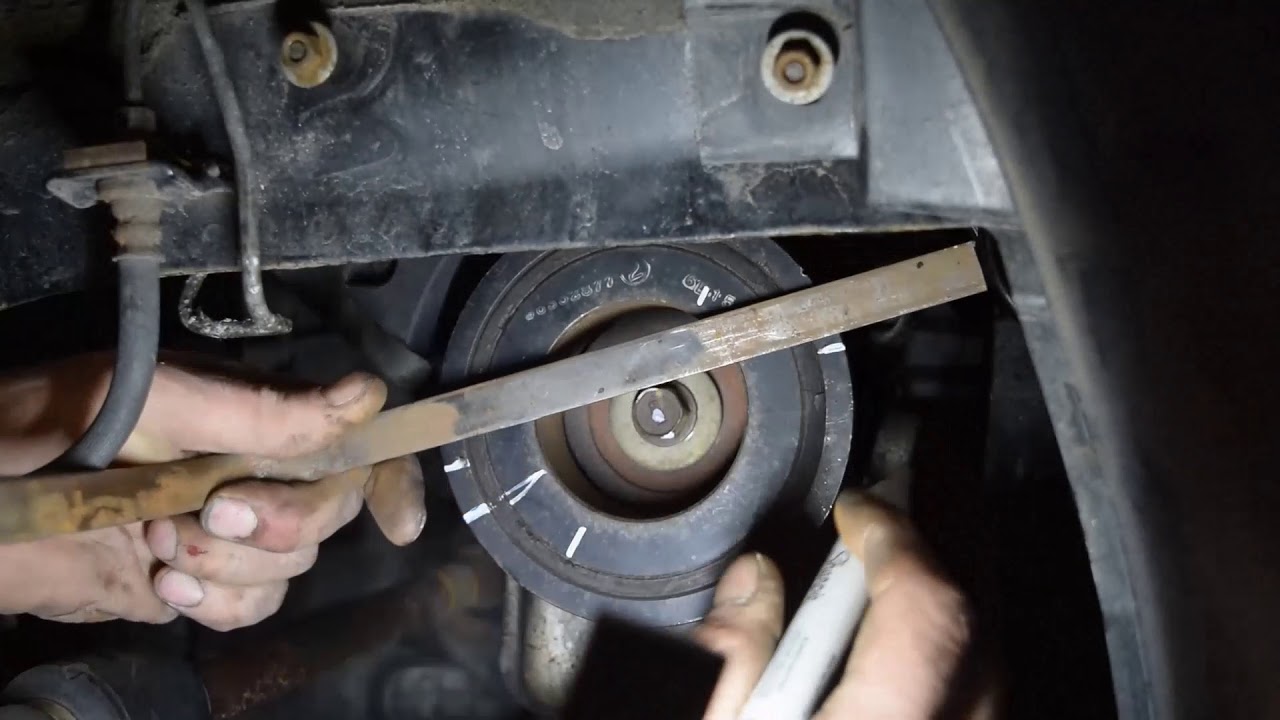

- Immobilize the Crankshaft: This is often the trickiest part. You need to prevent the crankshaft from rotating while you apply torque to the bolt. Several methods exist:

- Crankshaft Holding Tool: This specialized tool locks onto the crankshaft pulley or flywheel, preventing it from turning. There are various designs available, tailored to specific engine types.

- Flywheel Locking Tool: On manual transmission vehicles, a tool can be inserted into the flywheel housing to lock the flywheel.

- "Rope Trick" (Proceed with Caution): This involves feeding a length of soft rope into a cylinder through the spark plug hole to prevent piston movement. This method carries a risk of damaging the engine if the rope isn't properly positioned or if too much force is applied.

- Clean the Threads: Ensure that the threads on both the bolt and the crankshaft are clean and free of debris. A wire brush can be helpful for removing rust or dirt.

- Apply Lubricant (If Specified): Some manufacturers specify the use of a particular lubricant (e.g., engine oil or threadlocker) on the bolt threads. Consult the service manual.

- Initial Tightening: Tighten the bolt to the initial torque specification using the torque wrench.

- Angle Tightening (If Applicable): If the bolt is a TTY type, follow the manufacturer's instructions for angle tightening. This typically involves using an angle gauge or electronic torque wrench to rotate the bolt an additional number of degrees.

- Verify Torque: After tightening, double-check the torque value using the torque wrench to ensure that it is within the specified range.

Manufacturer Examples and Common Pitfalls

Different manufacturers employ varying designs and tightening procedures for crankshaft pulley bolts. For example, Honda engines often use a relatively small bolt with a moderate torque specification, while some Ford engines use a larger bolt with a significantly higher torque requirement. BMW is known to use a stretch bolt with a specific angle tightening sequence.

Here are some common pitfalls to avoid:

- Using the wrong torque specification: Always consult the service manual for your specific vehicle.

- Using an uncalibrated torque wrench: Torque wrenches should be calibrated regularly to ensure accuracy.

- Not immobilizing the crankshaft properly: This can lead to inaccurate torque readings and damage to the engine.

- Reusing TTY bolts: TTY bolts must be replaced after each use.

- Using an impact wrench to tighten the bolt: Impact wrenches can easily over-torque or under-torque the bolt.

Real-World Considerations and Recommendations

Successfully tightening a crankshaft pulley bolt requires a combination of knowledge, skill, and the right tools. If you're not comfortable performing this task yourself, it's best to leave it to a qualified mechanic. However, for those who are determined to tackle this challenge, here are some recommendations:

- Invest in a quality torque wrench: A reliable torque wrench is essential for ensuring accurate torque readings.

- Obtain the vehicle's service manual: The service manual contains detailed instructions and torque specifications for your specific vehicle.

- Use a crankshaft holding tool: A crankshaft holding tool is the safest and most effective way to immobilize the crankshaft.

- Take your time and double-check your work: Rushing through the process can lead to mistakes.

- Consider using an electronic torque wrench: These wrenches provide digital displays and can store torque values, making it easier to achieve accurate results, especially when angle tightening is involved.

- Practice on less critical fasteners: Before tackling the crankshaft pulley bolt, practice using the torque wrench on less critical fasteners to get a feel for how it works.

Properly torquing the crankshaft pulley bolt is more than just tightening a fastener; it's about ensuring the long-term reliability and performance of your engine. By understanding the principles behind torque, using the correct tools and procedures, and paying attention to detail, you can confidently tackle this challenging task and ensure a job well done.