How To Use A/c Vacuum Pump

So, you're ready to tackle some A/C work, huh? That’s ambitious, and with the right knowledge and tools, totally doable. One of the most critical tools in your A/C arsenal is the vacuum pump. This isn't just some fancy gadget; it's essential for properly servicing your car's air conditioning system. We're going to dive deep into how to use an A/C vacuum pump, covering everything from its purpose to troubleshooting. Think of this as your comprehensive guide to getting that cold air blowing again. We will be discussing the theory and procedure, including best practices to ensure a long-lasting A/C repair.

Purpose of Using an A/C Vacuum Pump

Before we get into the nitty-gritty, let's understand why you need a vacuum pump. The primary purpose is twofold: removing air and moisture from the A/C system.

- Removing Air: Air contains nitrogen and oxygen, which are non-condensable gases. These gases will increase the pressure in your A/C system, reducing its efficiency and potentially damaging components. Think of it like trying to compress a spring with solid objects wedged between the coils. It just won't work right.

- Removing Moisture: Moisture (water vapor) is even worse. It can react with the refrigerant to form acids, which corrode the inside of the system. It can also freeze at the expansion valve or orifice tube, blocking refrigerant flow and crippling your cooling capacity.

By drawing a vacuum, you effectively boil off any remaining moisture inside the system at room temperature. The lower the pressure (the deeper the vacuum), the lower the boiling point of water. This is crucial for a reliable and efficient A/C repair. Skipping this step is like painting over rust – it might look good for a little while, but the underlying problem will quickly resurface.

Key Specs and Main Parts

A typical A/C vacuum pump consists of a few key components:

- Pump Body: This houses the motor and pumping mechanism. Usually made of durable metal, often aluminum or cast iron.

- Motor: Provides the power to drive the pump. Horsepower (HP) is a key spec, as is voltage (usually 110V or 220V).

- Vacuum Gauge: Displays the vacuum level, usually in inches of mercury (inHg) or microns. Microns are a much finer measurement, with 1 micron being equal to 0.0000393701 inches of mercury. A good pump will pull down to at least 500 microns (or 29.9 inHg).

- Oil Reservoir: Holds the vacuum pump oil, which is essential for lubricating and sealing the pump. Keeping the oil clean and at the correct level is critical for proper operation.

- Intake Port(s): Where you connect your A/C manifold gauge set hoses. These are usually standard sizes (1/4" SAE, 3/8" SAE).

- Exhaust Port: Where the extracted air and moisture are expelled. Some pumps have a built-in oil mist filter to minimize oil discharge.

- Ballast Valve: Introduces a small amount of air into the pump to help purge moisture from the oil.

Key Specs to look for include:

- CFM (Cubic Feet per Minute): This indicates the pump's displacement or how much air it can move per minute. Higher CFM generally means faster evacuation. A 3-4 CFM pump is often adequate for smaller automotive A/C systems. Larger systems, especially on trucks or SUVs, might benefit from a 5-7 CFM pump.

- Ultimate Vacuum: The lowest vacuum level the pump can achieve, usually measured in microns. Lower is better. Aim for at least 500 microns.

How It Works

A vacuum pump uses a rotary vane design. Inside the pump, there's a rotor with vanes that slide in and out. As the rotor spins, the vanes create chambers of increasing and decreasing volume. As the chamber increases in volume, it pulls air from the A/C system through the intake port. As the chamber decreases in volume, it compresses the air and expels it through the exhaust port. Vacuum pump oil provides lubrication for the moving parts and seals the clearances to maintain a high vacuum.

The ballast valve allows a small amount of air to be introduced into the pump during operation. This air helps to vaporize any moisture that may have condensed in the pump oil, which then helps to push it out the exhaust valve, preserving the pumps effectiveness.

Real-World Use and Basic Troubleshooting Tips

Here's how to use your A/C vacuum pump effectively:

- Connect the Pump: Connect your A/C manifold gauge set to the A/C system service ports. Connect the center (yellow) hose from the manifold gauge set to the vacuum pump’s intake port. Make sure all connections are tight.

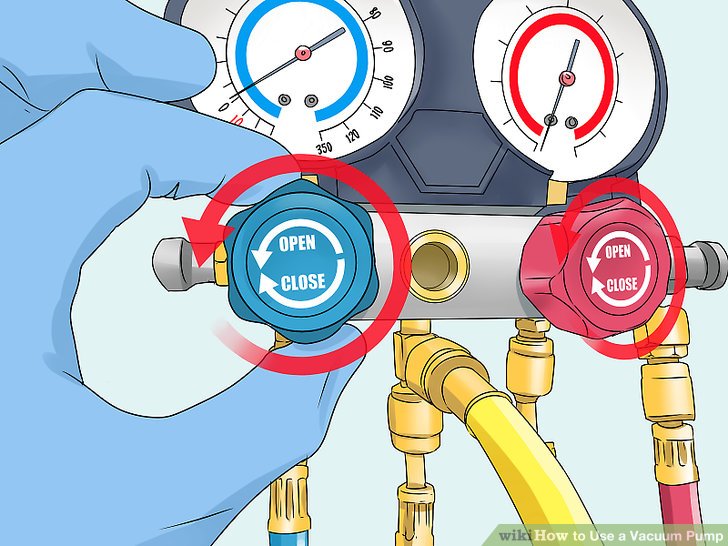

- Prepare the Pump: Ensure the vacuum pump oil is at the correct level and is clean. If the oil is dirty or contaminated, change it. Open both the high and low side valves on your manifold gauge set.

- Start the Pump: Turn on the vacuum pump.

- Evacuate the System: Allow the pump to run for at least 30-60 minutes. Longer is better, especially if you suspect a large amount of moisture in the system. Observe the vacuum gauge on your manifold. It should steadily decrease. If the system has been opened for repairs, it may be required to run the pump even longer, up to 2 hours.

- Isolate and Check for Leaks: Once you've achieved the desired vacuum level (e.g., 500 microns), close both the high and low side valves on your manifold gauge set. Turn off the vacuum pump. Monitor the vacuum gauge for at least 30 minutes. If the vacuum holds steady, you're good to go. If the vacuum drops, you have a leak in the system.

- Break the Vacuum: With the valves on the A/C system closed, connect a refrigerant source to the center port on the manifold set. Introduce a small amount of refrigerant to relieve the vacuum before disconnecting the manifold.

Troubleshooting:

- Pump Doesn't Pull a Vacuum: Check the oil level, ensure the connections are tight, and make sure the ballast valve is closed (unless you are purging the oil, in which case you would open it for a short time). If the pump is old, the vanes may be worn.

- Pump Runs Noisily: Low oil or contaminated oil. Change the oil.

- Slow Evacuation: Could be a low CFM pump, leaks in your connections, or a heavily contaminated system.

- Cannot Reach Desired Vacuum: Leak in the system is the most common culprit. Use a leak detector to find and repair the leak. It could also be a pump nearing the end of its life.

Safety

Working with A/C systems involves pressurized refrigerants, which can be dangerous if handled improperly. Always wear safety glasses and gloves. Refrigerant can cause frostbite if it comes into contact with your skin. Never release refrigerant into the atmosphere; it's illegal and environmentally damaging. Always recover refrigerant using a recovery machine. Furthermore, the vacuum pump itself uses electricity, so make sure your hands are dry and you're working in a dry environment to prevent electrical shock.

Always use the proper personal protective equipment (PPE) when servicing an A/C system.

Conclusion

Using an A/C vacuum pump is crucial for effective A/C repairs. Understanding its operation, key specs, and troubleshooting techniques can help you complete successful A/C system repairs and maintenance, saving you money and the hassle of relying on a mechanic for simple repairs.

If you want to delve deeper, we have the A/C System Diagram file available for download. It's a valuable resource for understanding the complete A/C system layout and components. With this knowledge, you'll be well-equipped to tackle most A/C related issues and ensure optimal cooling performance in your vehicle.