How To Work On A Car

So, you're ready to tackle some serious work on your car. Excellent! Getting hands-on is the best way to truly understand your vehicle, save money on labor costs, and even customize it to your exact liking. This guide will walk you through the fundamentals of working on your car, focusing on how to use a car's schematic diagram for repairs, maintenance, and modifications. Think of this as your advanced DIY handbook. I'm assuming you're already comfortable with basic tools and safety procedures. If not, brush up on those before continuing!

Understanding Automotive Diagrams: Your Car's Blueprints

A car's schematic diagram (also often called a wiring diagram, especially when dealing with electrical systems) is essentially a blueprint for how its various components interact. It uses symbols and lines to represent parts and connections, allowing you to trace circuits, identify component locations, and understand how systems function. Without it, troubleshooting electrical problems is like navigating a maze blindfolded.

Purpose: Why Bother with Diagrams?

Why should you spend time learning to decipher these complex-looking diagrams? Here’s why:

- Accurate Repairs: Diagrams pinpoint the exact components involved in a problem, preventing you from replacing perfectly good parts (a common and costly mistake).

- Efficient Troubleshooting: You can trace circuits and identify fault locations quickly.

- Safe Modifications: When adding aftermarket accessories (lights, stereos, etc.), a diagram helps you tap into the correct circuits safely and without damaging the car's electrical system.

- Deep Understanding: Working with diagrams solidifies your understanding of how your car's systems work, empowering you to diagnose and fix issues independently.

Key Specs and Main Parts Represented

Automotive diagrams can be highly specialized, focusing on specific systems like:

- Engine Management: Covers sensors, actuators, the ECU (Engine Control Unit, sometimes referred to as the PCM – Powertrain Control Module), and related wiring.

- Transmission Control: Shows the transmission control module (TCM), solenoids, sensors, and wiring for automatic transmissions.

- Body Electrical: Includes lighting, power windows, door locks, airbags, and other interior and exterior electrical systems.

- Anti-lock Braking System (ABS): Details the ABS module, wheel speed sensors, hydraulic unit, and related wiring.

- Climate Control: Illustrates the components of the A/C and heating systems, including the compressor, blower motor, sensors, and controls.

Within these diagrams, you'll typically find representations of:

- Power Sources: Battery, alternator, fuses, relays.

- Sensors: Measuring parameters like temperature, pressure, speed, and position. Examples include O2 sensors, MAP sensors, and crankshaft position sensors.

- Actuators: Components that perform actions based on signals from the ECU/PCM, such as fuel injectors, solenoids, and motors.

- Control Modules: The "brains" of the system, processing sensor data and controlling actuators.

- Wiring Harnesses: Bundles of wires connecting different components.

- Ground Points: Connections to the vehicle's chassis, providing a return path for electrical current. These are critical for proper electrical function.

Symbols: Decoding the Diagram Language

Diagrams use a standardized set of symbols to represent components and connections. Here's a breakdown of common symbols:

- Lines: Indicate wires. Solid lines typically represent powered circuits, while dashed lines might indicate ground circuits or control signals. Line thickness can sometimes indicate wire gauge (thicker lines = thicker wires, able to handle more current).

- Circles: Often represent lights, sensors, or switches. The symbol inside the circle clarifies the specific component.

- Squares/Rectangles: Typically used for relays, control modules, or fuses.

- Resistors: Represented by a zigzag line.

- Capacitors: Two parallel lines.

- Diodes: Triangle pointing to a vertical line.

- Ground Symbol: Usually three horizontal lines, decreasing in size, connected to a vertical line.

- Connectors: Show where wires plug into each other. The specific connector type might be indicated with a code (e.g., "C101").

Colors: Wires are often color-coded on diagrams. This corresponds to the actual wire colors in the car, making it easier to identify them. Always verify wire color before cutting or splicing! Common color codes include:

- BK: Black (Ground)

- RD: Red (Power)

- BL: Blue

- GN: Green

- YW: Yellow

- WT: White

- OR: Orange

- VT: Violet

Diagrams may also include numbers or alphanumeric codes next to wires or components. These are reference designators that help you locate the physical parts in the car or find related information in other technical documents. Always refer to the legend or key provided with the diagram to fully understand the symbols and codes used.

How It Works: Tracing Circuits

The key to using a diagram is to trace circuits. Start with the power source (usually the battery) and follow the path of the current through the circuit to the component you're interested in. Look for switches, relays, fuses, and sensors along the way. A circuit is complete when it provides a path from the power source to the component and back to ground.

For example, let's say you're troubleshooting a headlight that's not working. The diagram will show you the circuit: Battery -> Fuse -> Headlight Switch -> Headlight Relay -> Headlight -> Ground. If you suspect a bad relay, you can use a multimeter to check for voltage at the relay's power and ground terminals. You can also check if the relay is receiving a signal from the headlight switch to activate. If the relay checks out, you can then trace the circuit further to the headlight connector itself.

Real-World Use: Basic Troubleshooting Tips

Here are some practical troubleshooting tips using diagrams:

- No Power? Check the Fuse: This is the most common cause of electrical problems. The diagram will show you which fuse protects the circuit you're working on.

- Component Not Working? Check the Ground: A poor ground connection can prevent a component from functioning properly. Use the diagram to locate the ground point and ensure it's clean and securely attached to the chassis.

- Use a Multimeter: A multimeter is your best friend for electrical troubleshooting. Use it to check for voltage, continuity (a complete circuit), and resistance (opposition to current flow).

- Backprobe Connectors: Use a backprobe (a thin, pointed probe) to measure voltage or continuity at a connector without disconnecting it. This allows you to test the circuit under load.

- Isolate the Problem: If a circuit isn't working, systematically disconnect components one at a time to isolate the fault. For example, if multiple lights on a circuit are out, disconnect them one by one to see if one of them is shorting out the circuit.

Safety: Handle with Care

Working on cars can be dangerous, especially when dealing with electrical systems. Here are some crucial safety precautions:

- Disconnect the Battery: Always disconnect the negative (-) battery terminal before working on the electrical system. This prevents accidental shorts and electrical shocks.

- Be Aware of the Airbag System: The airbag system is extremely sensitive. Follow the manufacturer's instructions for disabling the airbag system before working on any components near airbags or impact sensors. Incorrect handling can cause airbags to deploy, resulting in serious injury.

- High-Voltage Systems: Hybrid and electric vehicles have high-voltage systems that can be lethal. Only qualified technicians should work on these systems.

- Fuel System: When working on the fuel system, be extremely careful to avoid sparks or open flames. Fuel is highly flammable. Relieve fuel pressure before disconnecting fuel lines.

- Use Proper Tools: Use insulated tools when working on electrical systems.

Remember to always consult your vehicle's repair manual for specific instructions and safety precautions related to your particular make and model.

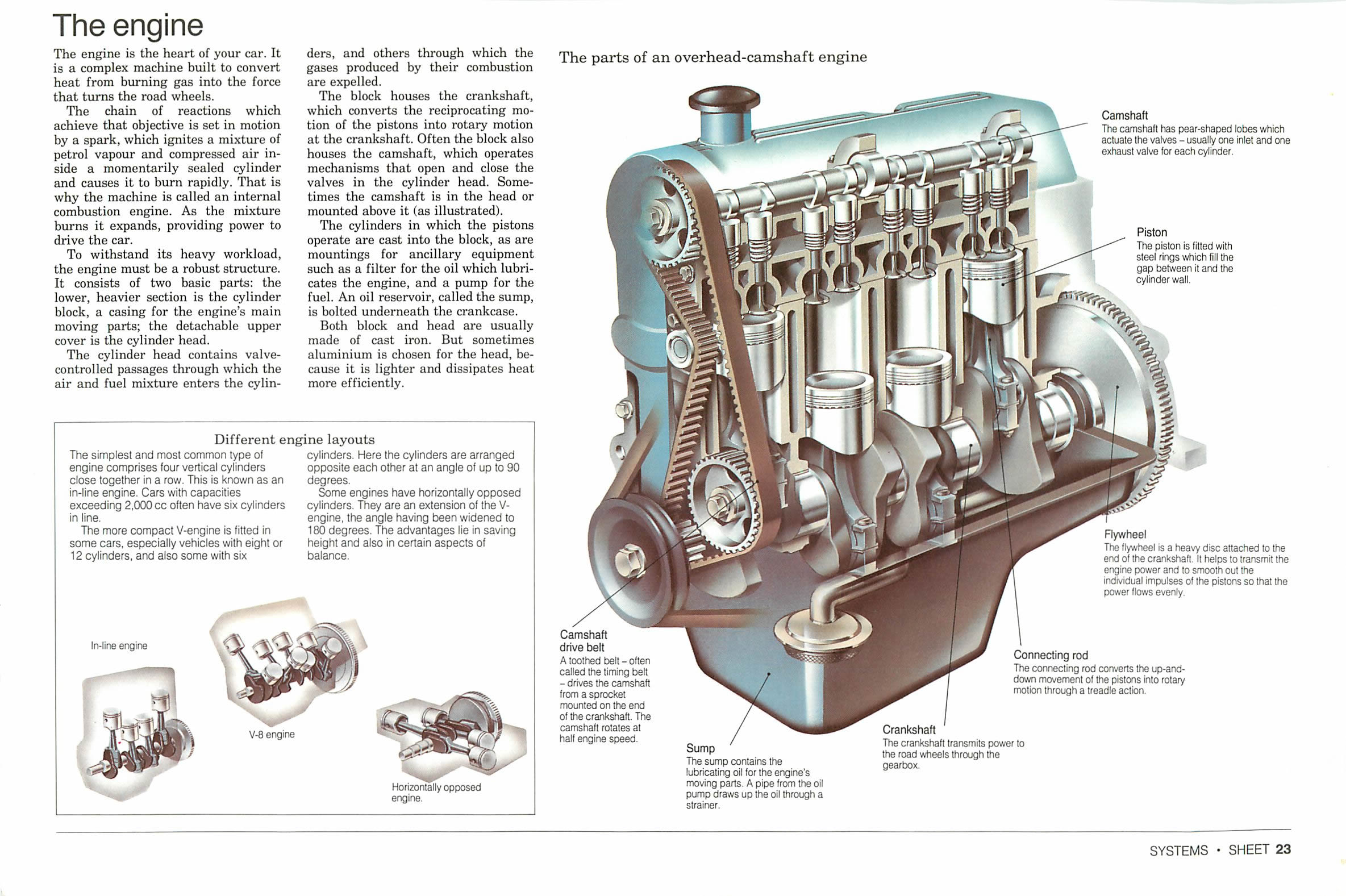

We have a sample of a generic automotive schematic diagram you can download. It is a great resource to get familiar with automotive diagrams. Use this information to get you started and remember to always consult your vehicle's repair manual before starting any repair.

Understanding and utilizing automotive diagrams is a powerful skill for any DIY mechanic. With practice and patience, you'll be able to confidently diagnose and repair a wide range of automotive problems. Good luck, and happy wrenching!