How To Work On Car Engines

So, you're ready to dive deeper into the heart of your vehicle – the engine. This isn't just about changing your oil anymore; we're talking about understanding how this mechanical marvel works, performing more complex repairs, and maybe even modifications. This guide will arm you with the knowledge to confidently tackle more advanced engine work.

Understanding Your Engine: A Deep Dive

Let's get one thing straight: working on engines can be challenging, but with the right knowledge and a systematic approach, it's incredibly rewarding. We'll cover essential concepts, components, and best practices to help you succeed.

Why This Knowledge Matters

Having a solid understanding of engine mechanics isn't just for professional mechanics. For the experienced DIYer, it opens doors to:

- Advanced Repairs: Tackle issues beyond basic maintenance, like replacing sensors, diagnosing misfires, or even rebuilding parts of the engine.

- Performance Tuning: Understanding the engine's inner workings allows you to optimize its performance for improved horsepower, fuel efficiency, or both.

- Informed Modifications: When upgrading components (intake, exhaust, etc.), you'll be able to make smarter decisions based on how those changes will impact the entire engine system.

- Cost Savings: Labor costs for engine work can be substantial. Being able to diagnose and fix problems yourself can save you a significant amount of money.

- Personal Satisfaction: There's a unique sense of accomplishment that comes with understanding and working on your own vehicle.

Key Specs and Main Parts

Let's break down the fundamental components and specifications you'll encounter when working on engines.

Core Engine Components

- Cylinder Block: The foundation of the engine, containing the cylinders where combustion occurs. Typically made of cast iron or aluminum.

- Cylinder Head: Sits atop the cylinder block, containing the valves, valve springs, and often the camshaft(s). Responsible for controlling the intake and exhaust processes.

- Pistons: Move up and down within the cylinders, driven by the expanding gases from combustion. Connected to the connecting rods.

- Connecting Rods: Connect the pistons to the crankshaft, transferring the linear motion of the pistons into rotational motion.

- Crankshaft: Converts the reciprocating motion of the pistons into rotary motion, which is then used to power the vehicle.

- Valves: Control the flow of intake air and exhaust gases into and out of the cylinders.

- Camshaft: Controls the opening and closing of the valves.

- Timing Belt/Chain: Connects the crankshaft to the camshaft, ensuring proper timing of the valve train.

- Intake Manifold: Distributes the air-fuel mixture (or just air in direct injection engines) to the cylinders.

- Exhaust Manifold: Collects exhaust gases from the cylinders and directs them to the exhaust system.

Key Specifications

- Displacement: The total volume of all cylinders in the engine, usually measured in liters or cubic inches.

- Compression Ratio: The ratio of the cylinder volume at the bottom of the stroke to the volume at the top of the stroke. Higher compression ratios generally result in more power.

- Bore and Stroke: The diameter of the cylinder (bore) and the distance the piston travels (stroke). These dimensions significantly impact engine characteristics.

- Horsepower and Torque: Horsepower is a measure of the engine's power output, while torque is a measure of its rotational force.

- Firing Order: The sequence in which the cylinders fire in a multi-cylinder engine. Proper firing order is crucial for smooth engine operation.

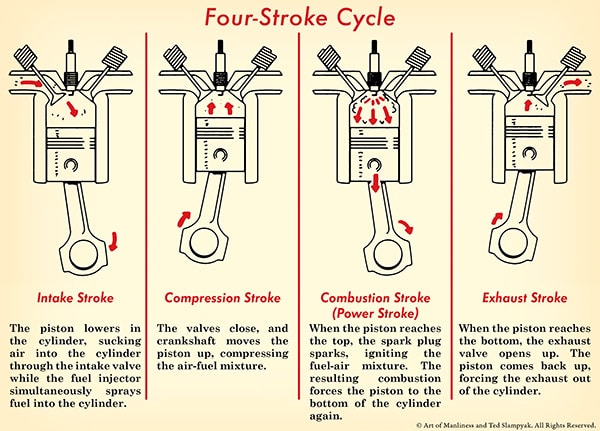

How It Works: The Four-Stroke Cycle

Most automotive engines operate on the four-stroke cycle: intake, compression, combustion (or power), and exhaust.

- Intake: The intake valve opens, and the piston moves down, drawing a mixture of air and fuel (or just air in direct injection engines) into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture.

- Combustion (Power): The spark plug ignites the compressed air-fuel mixture, creating an explosion that forces the piston down. This is the power stroke.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder.

Real-World Use: Basic Troubleshooting Tips

Here are a few common engine problems and some basic troubleshooting steps:

- Misfires: Rough idling, loss of power, and a check engine light can indicate a misfire. Check spark plugs, ignition coils, and fuel injectors. A faulty sensor could also be the culprit.

- Overheating: Caused by low coolant, a faulty thermostat, a leaking radiator, or a blown head gasket. Never open a hot cooling system.

- Low Oil Pressure: Can indicate a low oil level, a worn oil pump, or internal engine damage. Address immediately to prevent serious engine damage.

- Excessive Oil Consumption: May be caused by worn piston rings, valve seals, or external leaks.

- Check Engine Light (CEL): Use an OBD-II scanner to read the trouble codes. These codes provide valuable clues to the source of the problem. Remember that the code only points to a *potential* cause, not a guaranteed one. Further diagnosis is almost always needed.

Important: Always consult your vehicle's repair manual for specific troubleshooting procedures and diagnostic information.

Safety First: Handling Risky Components

Engine work involves potential hazards. Here are some key safety precautions:

- High Temperatures: Engines get extremely hot. Allow the engine to cool completely before working on it.

- Flammable Liquids: Gasoline and other engine fluids are flammable. Work in a well-ventilated area and avoid open flames.

- High Voltage: The ignition system can generate high-voltage electricity. Disconnect the battery before working on electrical components.

- Moving Parts: Keep hands and clothing clear of moving parts, especially when the engine is running (e.g., during diagnostic testing).

- Chemicals: Wear appropriate protective gear, such as gloves and eye protection, when handling chemicals like coolant, brake fluid, and solvents.

- Springs: Valve springs and other springs can store a significant amount of energy. Use the correct tools and procedures when working with them to avoid injury.

- Exhaust Fumes: Never run an engine in an enclosed space. Exhaust fumes contain carbon monoxide, a deadly gas.

Never underestimate the potential dangers of working on engines. Always prioritize safety and use proper tools and procedures.

Final Thoughts

Working on car engines is a complex but rewarding endeavor. By understanding the fundamental principles, components, and safety precautions, you can confidently tackle more advanced repairs and modifications. Remember to always consult your vehicle's repair manual and seek professional assistance when needed.

We have a detailed engine diagram available for download, which provides a visual representation of the engine's components and their relationships. This diagram will be a valuable resource as you continue your journey into the world of engine mechanics.