Learn How To Drive Stick Shift

So, you’re thinking about tackling the stick shift. Good on you. While automatics might be the norm these days, mastering a manual transmission opens up a whole new level of driving control and understanding of how your car actually works. It's not just about nostalgia; knowing how to drive stick can get you out of a jam if you need to drive someone else's car, it gives you a better feel for performance driving, and frankly, it's just plain fun. Consider this guide your detailed roadmap to conquering the clutch. We'll delve into the mechanics, the feel, and the practicalities of driving a manual transmission.

Why This Matters: Understanding the Manual Transmission

Forget just getting from A to B. Understanding the manual transmission is crucial for a few reasons, even if you don't plan on driving one daily:

- Diagnostics and Repair: When your friend's car is acting up and they say "it's a problem with the transmission," knowing the basics allows you to have an intelligent conversation with the mechanic, potentially saving you time and money. You'll understand terms like "clutch slippage," "synchros," and "shift linkage" instead of staring blankly.

- Performance Driving: Manual transmissions offer far more control over the engine's power output. This is essential for performance driving, whether on a track or just navigating challenging roads. You can choose the optimal gear for maximum acceleration or engine braking.

- Emergency Situations: What if you need to drive someone else’s vehicle in an emergency and it's a manual? Knowing the basics could be a lifesaver.

- Deeper Automotive Understanding: Learning the manual transmission gives you a fundamental understanding of power transfer in a car. You'll appreciate the nuances of engine torque, horsepower, and gear ratios in a way that's simply not possible with an automatic.

Key Specs and Main Parts of a Manual Transmission

The manual transmission, at its core, is a deceptively simple system. Let's break down the main components:

- Clutch: The clutch is the heart of the manual transmission. Its job is to temporarily disconnect the engine from the transmission, allowing you to change gears. It consists of a clutch disc (friction material), a pressure plate, and a release bearing.

- Flywheel: Bolted to the back of the engine, the flywheel provides a friction surface for the clutch disc and also stores rotational energy, smoothing out the engine's power pulses.

- Input Shaft: This shaft receives power directly from the engine, via the clutch. It spins at the same speed as the engine when the clutch is engaged (pedal up).

- Output Shaft: This shaft delivers power to the driveshaft, which in turn drives the wheels. The speed of the output shaft depends on the selected gear.

- Gears: Sets of gears with different sizes that provide various gear ratios. These ratios multiply the engine's torque or speed, depending on which gear is selected. A lower gear (e.g., 1st or 2nd) provides more torque for acceleration, while a higher gear (e.g., 5th or 6th) provides better fuel economy at higher speeds.

- Synchronizers (Synchros): These ingenious devices match the speed of the gears before they engage, preventing grinding. They are small friction rings that gently bring the gears to the same speed, allowing for smooth shifting.

- Shift Linkage: This system of rods, cables, or levers connects the gear shift lever in the cabin to the shift forks inside the transmission. It translates your gear selection into the movement of the shift forks.

- Shift Forks: These forks slide the synchronizers along the mainshaft, engaging the desired gear.

- Transmission Case: The housing that contains all the internal components of the transmission.

Gear Ratios Explained

Understanding gear ratios is fundamental. A gear ratio is simply the ratio of the number of teeth on the driven gear to the number of teeth on the driving gear. For example, a gear ratio of 3:1 means that the output shaft rotates once for every three rotations of the input shaft. This multiplies the torque delivered to the wheels but reduces the speed.

How It Works: The Dance of the Clutch and Gears

Here's a simplified breakdown of the process:

- Clutch Disengagement: You press the clutch pedal. This action disengages the clutch disc from the flywheel, disconnecting the engine from the transmission.

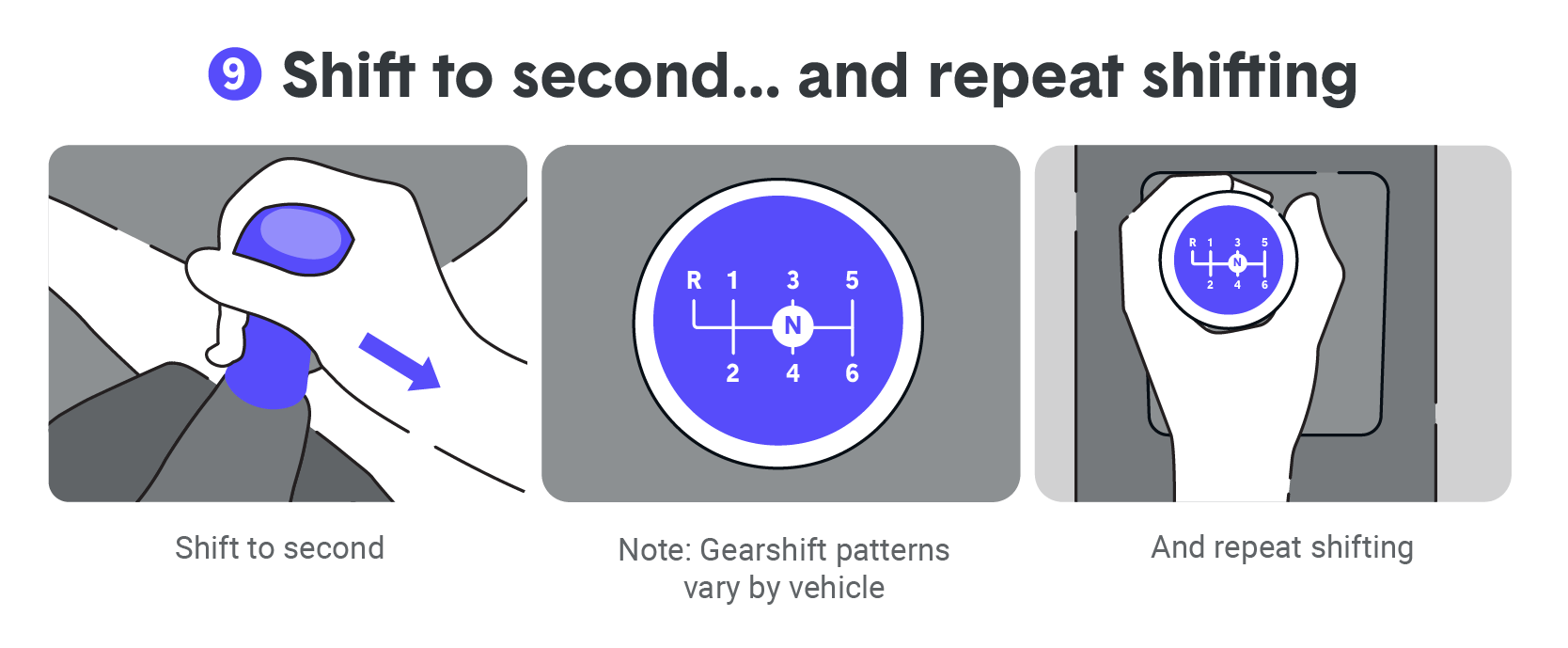

- Gear Selection: With the clutch disengaged, you move the gear shift lever to select the desired gear. This action moves the shift forks, which slide the synchronizers into engagement with the appropriate gear.

- Clutch Engagement: You slowly release the clutch pedal. This allows the clutch disc to gradually re-engage with the flywheel, transferring power from the engine to the transmission and, ultimately, to the wheels.

- Synchronization: As the clutch re-engages, the synchronizers ensure that the gears are rotating at the same speed, preventing grinding.

Real-World Use and Basic Troubleshooting

Let's talk about common issues and how to identify them:

- Clutch Slippage: The engine revs high but the car doesn't accelerate proportionally. This indicates a worn clutch disc that is no longer providing sufficient friction.

- Clutch Chatter: A shuddering or vibration when engaging the clutch. This can be caused by a contaminated clutch disc, worn engine mounts, or a warped flywheel.

- Grinding Gears: Difficulty shifting into gear, accompanied by a grinding noise. This is often caused by worn synchronizers or a misadjusted clutch linkage.

- Difficulty Shifting: Resistance when shifting into gear. This can be caused by a stiff or misadjusted shift linkage, low transmission fluid, or internal transmission damage.

Troubleshooting Tips

- Check the Clutch Linkage: Ensure the clutch linkage is properly adjusted. Too much slack can prevent the clutch from fully disengaging.

- Inspect the Transmission Fluid: Low or dirty transmission fluid can cause shifting problems. Check the fluid level and condition, and top up or replace it as needed.

- Listen for Noises: Pay attention to any unusual noises coming from the transmission. Grinding, whining, or clunking sounds can indicate serious internal damage.

Safety: Risky Components and Precautions

Working on a manual transmission involves potential hazards:

- Rotating Parts: The flywheel, input shaft, and output shaft rotate at high speeds when the engine is running. Keep hands and loose clothing clear of these parts.

- Heavy Components: Transmissions are heavy and can cause serious injury if dropped. Use proper lifting techniques and equipment.

- Springs Under Tension: The clutch pressure plate contains powerful springs that are under high tension. Use caution when disassembling the pressure plate, and wear safety glasses to protect your eyes.

- Fluid Leakage: Transmission fluid can be slippery and messy. Clean up spills immediately to prevent falls.

- Exhaust System: When working under the car, be mindful of the exhaust system. It can be extremely hot, even after the engine has been turned off for a while.

Always disconnect the battery before working on any electrical components related to the transmission. Always use jack stands when working under a vehicle. Never rely solely on a jack.

Ready to Dive Deeper?

This article provides a solid foundation, but there's always more to learn. For a more detailed visual understanding, we have a comprehensive manual transmission diagram available for download. This diagram includes labeled components, fluid pathways, and exploded views to give you an even deeper insight into the inner workings of a manual transmission. This is not just for theoretical understanding; it's a practical tool you can use when diagnosing problems or even attempting repairs. The diagram provides a level of detail that can be invaluable when working on your own vehicle or helping a friend out.

With dedication and a bit of grease under your fingernails, you'll be shifting gears like a pro in no time. Happy driving!