Lights In Cars And What They Mean

Understanding your car's electrical system, particularly its lighting, is crucial for both routine maintenance and more complex modifications. This article provides an in-depth look at automotive lighting systems, focusing on the purpose, key components, and troubleshooting techniques that every experienced DIY car enthusiast should know. We'll cover everything from basic bulb identification to deciphering wiring diagrams, empowering you to diagnose and repair lighting issues with confidence.

Purpose of Understanding Automotive Lighting

Why bother diving into the intricacies of automotive lighting? Several compelling reasons exist:

- Repairs & Maintenance: Identifying a faulty bulb is easy, but tracing a wiring issue or understanding why a light isn't working requires a deeper understanding of the system.

- Modifications: Adding aftermarket lights (fog lights, LED strips, etc.) requires proper wiring and understanding of the existing circuits to avoid overloading or causing shorts.

- Diagnostics: Modern cars integrate lighting systems with the vehicle's computer. Understanding the lighting circuits can help diagnose broader electrical problems.

- Safety: Properly functioning lights are critical for safe driving, especially at night or in inclement weather.

- Learning: Understanding the basics of automotive lighting circuits is a great entry point for further exploration into automotive electrical systems.

Key Specs and Main Parts of a Car's Lighting System

A typical automotive lighting system comprises several key components, each with its own specifications and functions. Knowing these components is essential before attempting any repairs or modifications.

Main Components:

- Light Bulbs: The heart of the system, available in various types including incandescent, halogen, LED, and HID (High-Intensity Discharge). Each type has its own voltage, wattage, and light output characteristics.

- Fuses & Relays: Fuses protect circuits from overcurrent, while relays act as electrically controlled switches, allowing a low-current circuit (e.g., a headlight switch) to control a high-current circuit (e.g., headlights).

- Switches: Control the activation of various lights, from headlights and taillights to turn signals and interior lights.

- Wiring Harness: A bundle of wires that connects all the lighting components. Wire gauge (thickness) is crucial; thicker wires can handle higher currents.

- Control Modules (BCM, ECM): In modern vehicles, the Body Control Module (BCM) or Engine Control Module (ECM) often control lighting functions, enabling features like automatic headlights or daytime running lights (DRLs).

- Grounding Points: Critical for completing the electrical circuit. Poor grounding can cause dim lights, flickering, or complete failure.

Key Specifications:

- Voltage: Typically 12V DC in most vehicles.

- Wattage: The power consumption of each bulb, measured in watts (W). Exceeding the rated wattage can overload the circuit and blow fuses.

- Amperage: The current flowing through the circuit, measured in amps (A). Understanding the amperage draw is crucial when adding aftermarket lights.

- Wire Gauge: The thickness of the wires, measured in AWG (American Wire Gauge). Lower AWG numbers indicate thicker wires.

- Lumens: A measure of the total light output of a bulb. Higher lumens indicate a brighter light.

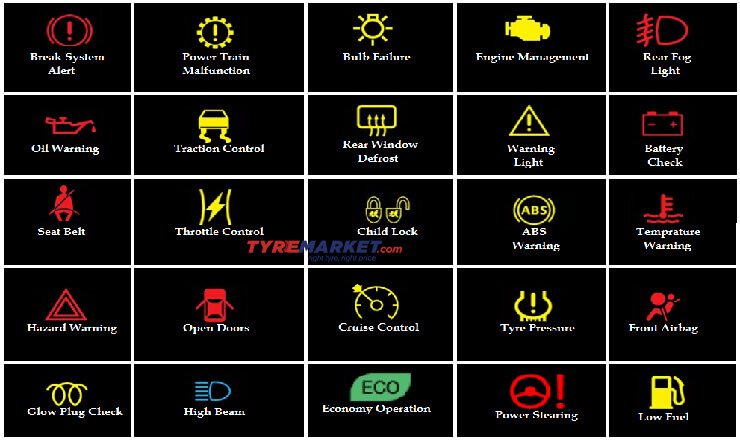

Understanding Lighting System Symbols

Wiring diagrams use standardized symbols to represent electrical components. Learning these symbols is crucial for interpreting the diagrams correctly.

- Lines: Represent wires. Solid lines indicate a direct connection, while dashed lines may indicate a shielded wire or a connection through a connector.

- Colors: Wires are often color-coded for identification. Common colors include red (power), black (ground), and various colors for signal wires (e.g., blue for headlight high beam).

- Icons: Specific icons represent each component:

- Bulb: Typically a circle with an "X" inside.

- Resistor: A jagged line.

- Capacitor: Two parallel lines.

- Ground: A series of horizontal lines decreasing in length.

- Fuse: A wavy line between two dots.

- Relay: A coil (representing the electromagnet) and a switch (representing the contacts).

- Connectors: Often represented by a square or rectangle, indicating a point where wires can be disconnected.

- Numbers & Letters: Often used to label wires and connectors for identification.

Understanding these symbols is like learning a new language. Practice interpreting simple circuits first before tackling more complex diagrams.

How Automotive Lighting Works: A Simplified Explanation

At its core, an automotive lighting system is a relatively simple circuit. Power from the battery flows through a fuse, then to a switch. When the switch is closed (turned on), the circuit is completed, and current flows through the light bulb, causing it to illuminate. The current then returns to the battery through a ground connection.

Relays are used when the switch cannot handle the high current required by the light bulb. In this case, the switch controls a low-current circuit that activates the relay. The relay then closes the high-current circuit, allowing power to flow to the light bulb.

Modern vehicles often use control modules to manage lighting functions. These modules receive input from sensors (e.g., ambient light sensor for automatic headlights) and control the lights accordingly. They may also monitor the lighting system for faults and trigger warning lights on the dashboard.

Real-World Use: Basic Troubleshooting Tips

When a light stops working, follow these basic troubleshooting steps:

- Check the Bulb: This is the simplest and most common issue. Replace the bulb with a new one of the correct type and wattage.

- Check the Fuse: Use a multimeter or test light to check the fuse for continuity. If the fuse is blown, replace it with a new fuse of the same amperage rating. Never use a fuse with a higher amperage rating, as this can damage the wiring.

- Check the Ground Connection: Ensure that the ground connection is clean and tight. Corroded or loose ground connections can cause dim lights or flickering.

- Check the Switch: Use a multimeter to check for continuity through the switch when it is in the "on" position.

- Check the Wiring: Inspect the wiring for damage, such as frayed wires, broken connectors, or corrosion. Use a multimeter to check for continuity between different points in the circuit.

- Consult a Wiring Diagram: If you're still having trouble, consult a wiring diagram for your specific vehicle. This will help you trace the circuit and identify potential problem areas.

For example, if your headlights are not working, start by checking the headlight bulbs. If the bulbs are good, check the headlight fuse. If the fuse is blown, replace it. If the fuse blows again immediately, there is a short circuit in the wiring. You will need to trace the wiring to find the short.

Safety Considerations When Working with Automotive Lighting

Working with automotive electrical systems can be dangerous if proper precautions are not taken.

- Disconnect the Battery: Always disconnect the negative battery terminal before working on any electrical components. This will prevent accidental shorts and potential electric shock.

- Use Proper Tools: Use insulated tools designed for electrical work.

- Avoid Working in Wet Conditions: Water is a conductor of electricity.

- Be Careful with HID Bulbs: HID bulbs contain high-pressure gas and can explode if mishandled. Handle them with care and avoid dropping them.

- Do Not Overload Circuits: Adding too many lights to a circuit can overload the circuit and cause a fire. Consult a wiring diagram to determine the maximum load for each circuit.

The ballast for HID headlights stores very high voltage even after the car is turned off. Discharge any capacitors before handling. This is one of the riskiest components and should be handled with extreme care.

By understanding the principles outlined in this article, you'll be well-equipped to tackle most automotive lighting issues, saving time, money, and ensuring your vehicle's lighting system operates safely and efficiently.