What Are Cylinders In A Car

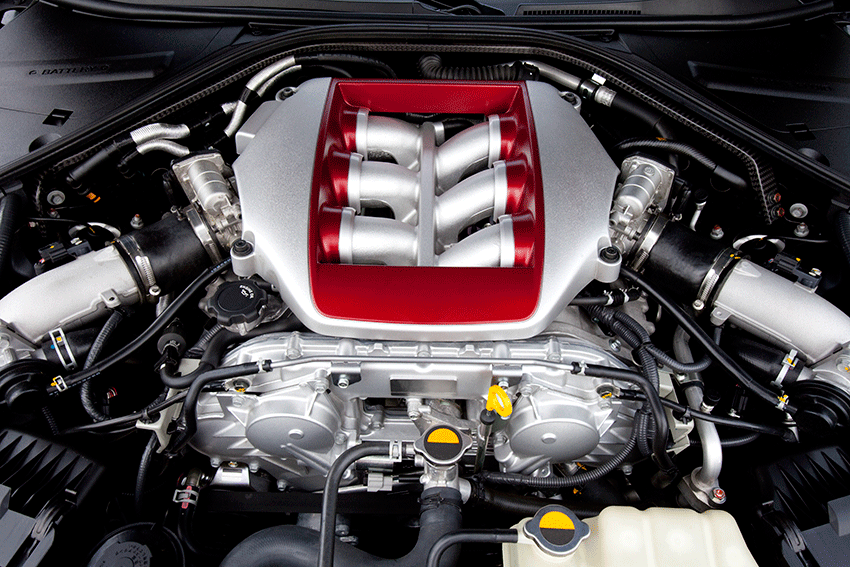

Hey there, fellow gearheads! Ever wonder what those "cylinders" are that everyone talks about when describing an engine? You hear about V6s, inline-4s, and maybe even a W12, and it all comes down to the number and arrangement of these crucial components. In this deep dive, we're going to dissect the cylinder – the heart of your engine – so you can understand its purpose, components, and operation. This isn’t just academic; understanding cylinders is vital for diagnosing engine problems, performing repairs, and even planning modifications. Plus, we've got a detailed diagram available for download that will serve as a fantastic visual aid.

Purpose and Why This Matters

The primary purpose of a cylinder is to provide a sealed chamber where combustion can occur. This controlled explosion pushes a piston, converting chemical energy from fuel into mechanical energy that ultimately turns your wheels. This is the fundamental principle behind the internal combustion engine. Understanding this process unlocks a deeper understanding of engine performance, efficiency, and potential problems.

This knowledge is crucial for:

- Diagnostics: Recognizing symptoms like misfires or low compression, and understanding which cylinder(s) are affected.

- Repairs: Knowing the parts involved in a cylinder and how to access them for replacement or repair.

- Modification: Planning performance upgrades that might affect cylinder pressure, temperature, or airflow.

- General Knowledge: Appreciating the engineering marvel that is the internal combustion engine!

Key Specs and Main Parts

Let's break down the essential components of a typical cylinder:

- Cylinder Bore: This is the internal diameter of the cylinder, usually measured in millimeters (mm) or inches. The bore, along with the piston's stroke (distance the piston travels), determines the engine's displacement (volume). A larger bore generally allows for more airflow and potential power.

- Piston: A cylindrical component that moves up and down inside the cylinder. It's connected to the connecting rod, which in turn is connected to the crankshaft. The piston's crown (top surface) is exposed to the combustion process.

- Piston Rings: These fit into grooves on the piston's outer surface and create a seal between the piston and the cylinder wall. They prevent combustion gases from escaping into the crankcase (blow-by) and also help scrape excess oil off the cylinder walls. Typically, there are compression rings (top) and an oil control ring (bottom).

- Connecting Rod: Connects the piston to the crankshaft. It transmits the force from the piston to the crankshaft, converting linear motion into rotary motion.

- Cylinder Head: Sits atop the cylinder block and contains the valves, spark plug (or injector in a diesel engine), and combustion chamber. It’s a complex casting with precisely machined passages for coolant and oil.

- Valves: Typically intake and exhaust valves. Intake valves open to allow air (or air-fuel mixture) into the cylinder, while exhaust valves open to allow exhaust gases to exit. Valve timing is crucial for optimal engine performance.

- Spark Plug (Gasoline Engines): Ignites the air-fuel mixture within the cylinder. Diesel engines use compression ignition, so they don't have spark plugs but instead use fuel injectors.

- Cylinder Liner (Sleeves): Some engines have cylinder liners, which are sleeves inserted into the cylinder block. These can be replaced if the cylinder bore becomes damaged, saving the cost of replacing the entire engine block.

Understanding these components is vital for visualizing how the engine works. The relationship between them is key to optimizing performance and troubleshooting problems.

How It Works: The Four-Stroke Cycle

Most modern car engines operate on the four-stroke cycle, which involves these four distinct phases:

- Intake Stroke: The piston moves downwards, creating a vacuum inside the cylinder. The intake valve opens, allowing air (or a mixture of air and fuel) to be drawn into the cylinder.

- Compression Stroke: The piston moves upwards, compressing the air-fuel mixture. Both intake and exhaust valves are closed. Compression increases the temperature of the mixture, making it easier to ignite.

- Combustion (Power) Stroke: At the top of the compression stroke, the spark plug ignites the compressed air-fuel mixture (in a gasoline engine). The resulting explosion forces the piston downwards, producing power.

- Exhaust Stroke: The piston moves upwards, pushing the burnt exhaust gases out of the cylinder through the open exhaust valve.

This cycle repeats continuously, providing the power to drive your vehicle. The precise timing of these events is controlled by the engine's timing system (timing belt or chain).

Real-World Use – Basic Troubleshooting

Here are some common cylinder-related problems and basic troubleshooting tips:

- Misfire: A misfire occurs when one or more cylinders fails to fire properly. This can be caused by a faulty spark plug, ignition coil, fuel injector, or low compression. Symptoms include rough idling, loss of power, and a check engine light. Start by checking the spark plugs and ignition coils. If those are fine, a compression test can help determine if there's a problem with the valves or piston rings.

- Low Compression: Low compression in a cylinder indicates a loss of sealing. This can be caused by worn piston rings, leaky valves, or a damaged cylinder head gasket. A compression test will reveal which cylinders have low compression. A leak-down test can help pinpoint the source of the leak.

- Oil Consumption: Excessive oil consumption can be caused by worn piston rings or valve stem seals. Blue smoke from the exhaust is a common symptom.

- Coolant in Oil: If you find coolant in your oil (milky-looking oil), it could indicate a blown head gasket or a cracked cylinder head or block. This is a serious problem that requires immediate attention.

Symbols and Conventions

Let's decipher some common symbols you might find in engine diagrams:

- Solid Lines: Typically represent physical components or fluid flow paths.

- Dashed Lines: Often indicate vacuum lines or control lines.

- Colors: Colors are used for clarity: Red might represent high-pressure oil, blue for coolant, and green for air or fuel. Check the specific diagram's legend for details.

- Arrows: Indicate the direction of flow (e.g., coolant flow, airflow).

- Hatching/Crosshatching: Indicates the material of a component (e.g., cast iron, aluminum).

Pay attention to the legend or key that accompanies any diagram. It will explain the specific symbols and conventions used.

Safety – Risky Components

Working on engine cylinders involves potential hazards. Here are some key safety considerations:

- High Temperatures: Engine components can be extremely hot, even long after the engine has been shut off. Allow the engine to cool completely before working on it.

- High Voltages: The ignition system generates high voltages. Disconnect the battery before working on the ignition system.

- Flammable Liquids: Gasoline and other engine fluids are flammable. Work in a well-ventilated area and avoid sparks or open flames.

- Sharp Edges: Engine components can have sharp edges. Wear gloves to protect your hands.

- Heavy Components: Cylinder heads and engine blocks are heavy. Use proper lifting techniques and equipment to avoid injury.

- Eye Protection: Always wear safety glasses to protect your eyes from debris.

Always consult the manufacturer's service manual for specific safety precautions and procedures. Improper repairs can lead to serious injury or damage to your vehicle.

Conclusion

Understanding the cylinders within your car's engine is key to effective diagnosis, repair, and even performance upgrades. Remember that careful observation, a methodical approach, and adherence to safety precautions are your best allies. By taking your time and diving deeper, you'll grow your knowledge and confidence in working on your car's engine.

We've prepared a downloadable cylinder diagram to enhance your understanding. This visual aid offers a detailed illustration of cylinder components and their interactions. You can access it at [hypothetical download link]. Use it to bolster your learning and reference during future repairs and projects.