What Are Cylinders In An Engine

Alright, let's dive into the heart of your engine: the cylinders. Understanding these vital components is crucial whether you're planning on performing routine maintenance, tackling a major repair, or just want to grasp how your car *really* works. Think of this explanation as a roadmap, and this article as the key to deciphering it.

Purpose of Understanding Cylinders

Why bother understanding the intricacies of your engine's cylinders? There are several compelling reasons:

- Repairs and Maintenance: Diagnosing misfires, understanding compression issues, and knowing when to replace piston rings all hinge on a solid understanding of cylinder function.

- Performance Tuning and Modification: If you're planning on boosting horsepower, knowing how cylinders handle pressure, heat, and combustion is paramount. Modifications like bore and stroke adjustments directly impact cylinder characteristics.

- Troubleshooting: A strange noise, a loss of power, or excessive oil consumption could stem from a problem within a cylinder. Knowing what to look for dramatically speeds up the diagnostic process.

- General Knowledge and Appreciation: Simply knowing how your car's engine converts fuel into motion is a satisfying accomplishment for any mechanically inclined individual.

Key Specs and Main Parts

Each cylinder is essentially a precisely machined chamber where combustion occurs. Let's break down the key components:

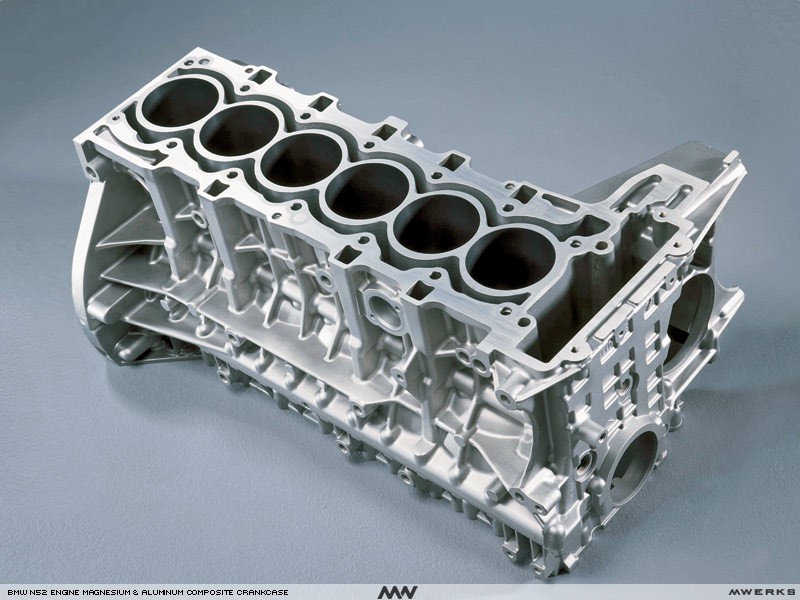

- Cylinder Block: The foundation of the engine, housing the cylinders themselves. Often made of cast iron or aluminum.

- Cylinder Bore: The precisely machined inner surface of the cylinder where the piston moves. Its diameter is a crucial specification.

- Piston: A cylindrical component that moves up and down within the cylinder bore. It's connected to the connecting rod.

- Piston Rings: Located in grooves around the piston, these rings create a seal against the cylinder wall, preventing combustion gases from escaping and controlling oil consumption. Types include compression rings, oil control rings, and wiper rings.

- Connecting Rod (Con-Rod): Connects the piston to the crankshaft, translating the piston's linear motion into rotational motion.

- Crankshaft: A rotating shaft that converts the reciprocating motion of the pistons into rotational motion, which ultimately drives the wheels.

- Cylinder Head: Sits atop the cylinder block, sealing the cylinders and housing the valves, spark plugs (in gasoline engines), and fuel injectors.

- Valves: Control the intake of air/fuel mixture and the exhaust of combustion gases. Intake valves are typically larger than exhaust valves.

- Spark Plug (Gasoline Engines): Ignites the air/fuel mixture within the cylinder.

- Fuel Injector: Sprays fuel into the cylinder or intake port.

Key Specifications:

- Bore: The diameter of the cylinder bore.

- Stroke: The distance the piston travels from its highest point (Top Dead Center - TDC) to its lowest point (Bottom Dead Center - BDC).

- Displacement: The volume swept by the piston as it moves from TDC to BDC. Calculated as: π * (Bore/2)² * Stroke * Number of Cylinders. This is often expressed in cubic centimeters (cc) or liters (L).

- Compression Ratio: The ratio of the cylinder volume when the piston is at BDC to the cylinder volume when the piston is at TDC. A higher compression ratio generally means more power, but it also increases the risk of detonation.

How It Works: The Four-Stroke Cycle

Most automotive engines operate on a four-stroke cycle, which consists of four distinct phases:

- Intake Stroke: The piston moves down, creating a vacuum in the cylinder. The intake valve opens, allowing the air/fuel mixture to be drawn into the cylinder.

- Compression Stroke: The intake valve closes, and the piston moves up, compressing the air/fuel mixture. This increases the mixture's temperature and pressure, making it easier to ignite.

- Combustion (Power) Stroke: At or near TDC, the spark plug ignites the compressed air/fuel mixture. The resulting explosion forces the piston down, generating power.

- Exhaust Stroke: The exhaust valve opens, and the piston moves up, pushing the burnt gases out of the cylinder and into the exhaust system.

Real-World Use: Basic Troubleshooting Tips

Cylinder issues can manifest in various ways. Here are a few common problems and how they relate to cylinder function:

- Misfires: A misfire occurs when one or more cylinders fail to fire correctly. This can be caused by faulty spark plugs, bad ignition coils, leaky fuel injectors, or compression problems.

- Low Compression: Low compression in a cylinder can indicate worn piston rings, leaking valves, or a blown head gasket. A compression test is a crucial diagnostic tool.

- Excessive Oil Consumption: Worn piston rings or damaged cylinder walls can allow oil to leak into the combustion chamber, leading to excessive oil consumption and blue smoke from the exhaust.

- Knocking or Pinging: This can be caused by detonation or pre-ignition within the cylinder. Detonation occurs when the air/fuel mixture explodes instead of burning smoothly, often due to excessive heat or high compression.

Basic Troubleshooting Steps:

- Check Spark Plugs: Inspect the spark plugs for signs of wear, fouling, or damage. A worn spark plug can cause misfires.

- Perform a Compression Test: This test measures the compression pressure in each cylinder. Low compression in one or more cylinders indicates a problem.

- Check for Vacuum Leaks: Vacuum leaks can disrupt the air/fuel mixture and cause misfires.

- Listen for Unusual Noises: Unusual noises, such as knocking or pinging, can indicate problems within the cylinders.

Safety Considerations

Working on an engine's cylinders involves inherent risks. Here are some key safety precautions:

- Disconnect the Battery: Always disconnect the negative battery cable before working on the engine to prevent electrical shocks.

- Allow the Engine to Cool: Never work on a hot engine. Allow it to cool completely before starting any repairs.

- Use Proper Tools: Using the right tools for the job is essential for safety and preventing damage to the engine.

- Wear Safety Glasses: Protect your eyes from debris and fluids.

- Be Aware of High-Pressure Components: Fuel injectors and other components can be under high pressure. Relieve the pressure before disconnecting them.

- Handle Fluids Carefully: Engine oil, coolant, and gasoline are hazardous. Wear gloves and avoid skin contact. Dispose of fluids properly.

- The timing chain or timing belt is a critical component that controls the valve timing. If it breaks or is improperly installed, it can cause severe engine damage.

Finally, remember that tackling cylinder work can be complex. If you're not comfortable with the procedures, it's always best to consult a qualified mechanic.

We have a detailed cylinder diagram available for download to further enhance your understanding. It includes detailed schematics and labeled parts. We recommend referring to this diagram during your learning process.