What Are Lifters In A Car

Welcome, fellow gearheads! Today, we're diving deep into the heart of your engine to understand a critical component often overlooked: lifters (also sometimes called tappets). Whether you're chasing that perfect idle, tackling a mysterious ticking noise, or simply expanding your automotive knowledge, understanding lifters is crucial. This isn't just academic; understanding lifters can help you diagnose engine problems, perform repairs, or even choose the right performance upgrades.

Purpose and Why This Matters

Lifters act as the intermediary between the camshaft and the valves in your engine. Think of them as tireless messengers, translating the rotational motion of the camshaft's lobes into the linear movement required to open and close the intake and exhaust valves. This synchronized dance is what allows your engine to breathe, combust fuel, and generate power. Understanding lifters is vital for a few key reasons:

- Diagnosis: A faulty lifter can cause a variety of engine problems, from annoying ticking noises to significant performance loss. Knowing how they work allows you to pinpoint the source of the problem.

- Repair: Replacing lifters can be a necessary part of engine maintenance or repair. Knowing the different types and how they interact with other engine components will make the repair smoother.

- Modification: When upgrading your camshaft for more power, you may also need to upgrade your lifters to match. Choosing the right lifter type for your application is critical to avoid damage and achieve the desired performance.

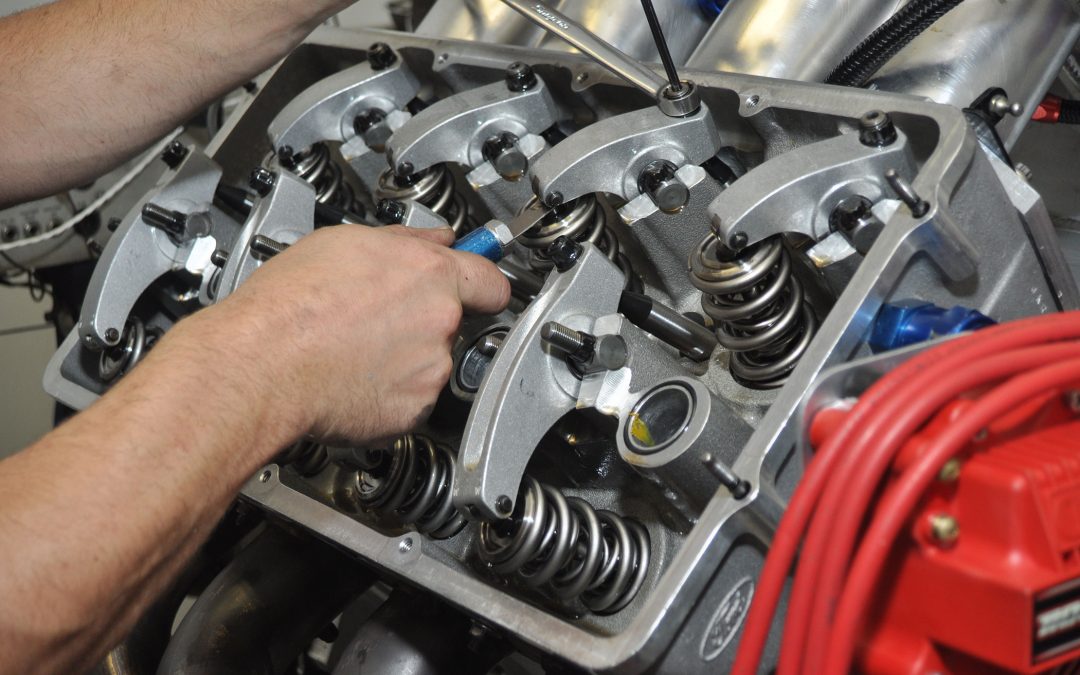

Key Specs and Main Parts

Lifters come in several different designs, each with its own characteristics and applications. Here's a breakdown of the main types:

Types of Lifters

- Hydraulic Lifters: These are the most common type in modern engines. They use engine oil pressure to maintain zero valve lash (the gap between the rocker arm and the valve stem). Hydraulic lifters automatically adjust for wear, making them relatively maintenance-free. They consist of a body, a plunger, a check valve, and a pushrod seat.

- Mechanical (Solid) Lifters: Also known as solid tappets, these lifters have no hydraulic mechanism. Instead, they require manual adjustment of valve lash. While they require more maintenance, they are preferred in high-performance applications because they are more reliable at high RPMs and provide a more precise valve opening and closing.

- Roller Lifters: These can be either hydraulic or mechanical, but they incorporate a roller wheel at the bottom that rides on the camshaft lobe. This reduces friction and wear compared to flat-bottom lifters, allowing for more aggressive camshaft profiles. They are common in high-performance and racing engines.

Main Parts of a Hydraulic Lifter

Understanding the components of a hydraulic lifter is key to understanding its function.

- Lifter Body: The main housing of the lifter, which sits in the lifter bore in the engine block.

- Plunger: A small piston inside the lifter body that moves up and down.

- Check Valve: A one-way valve that allows oil to enter the lifter but prevents it from escaping, maintaining pressure.

- Pushrod Seat: The cup or socket where the pushrod sits, transferring the lifter's motion to the rocker arm.

- Oil Inlet: A small hole that allows engine oil to enter the lifter.

How It Works

The basic principle is simple: as the camshaft rotates, its lobes push against the lifter. The lifter, in turn, pushes on the pushrod (if equipped), which then actuates the rocker arm. The rocker arm then opens the valve. The difference between hydraulic and mechanical lifters lies in how they maintain proper valve lash.

Hydraulic Lifter Operation

In a hydraulic lifter, engine oil is supplied to the lifter body. The check valve allows oil to fill the small chamber beneath the plunger. As the camshaft lobe pushes on the lifter, the oil-filled chamber acts as a solid link, transmitting the motion to the pushrod. If there is any valve lash, the plunger will move up slightly, filling the chamber with more oil and eliminating the gap. This self-adjusting mechanism is what keeps the valve lash at zero.

Mechanical Lifter Operation

Mechanical lifters, on the other hand, require manual adjustment of valve lash. A small gap is intentionally left between the rocker arm and the valve stem when the camshaft lobe is on its base circle. This gap allows for thermal expansion of the engine components. If the valve lash is too tight, the valve may not fully close, leading to compression loss and potential valve damage. If the valve lash is too loose, it can cause excessive valve train noise and reduced engine performance.

Real-World Use – Basic Troubleshooting Tips

Here's some common problems you might encounter and how to diagnose them:

- Ticking Noise: This is the most common symptom of a lifter problem. It can be caused by a collapsed hydraulic lifter, excessive valve lash in a mechanical lifter, or a worn lifter or camshaft lobe.

- Loss of Power: A collapsed lifter can prevent the valve from opening fully, leading to a loss of compression and reduced power.

- Rough Idle: A malfunctioning lifter can cause erratic valve timing, resulting in a rough and unstable idle.

Troubleshooting Steps

- Identify the Source: Use a mechanic's stethoscope to pinpoint the location of the ticking noise.

- Check Oil Pressure: Low oil pressure can prevent hydraulic lifters from properly functioning.

- Inspect Lifters: Remove the valve cover and inspect the lifters for wear or damage. For mechanical lifters, check and adjust the valve lash according to the manufacturer's specifications.

- Compression Test: Perform a compression test to identify cylinders with low compression, which could be caused by a valve not seating properly due to a lifter issue.

Safety – Highlight Risky Components

Working on the valve train involves several potential hazards. Here are some important safety considerations:

- Hot Engine: Never work on an engine when it's hot. Allow it to cool completely before starting any repairs.

- Moving Parts: Be extremely careful when working around moving parts, such as the camshaft and valve train. Keep your hands and tools clear of these areas.

- Eye Protection: Always wear safety glasses to protect your eyes from debris.

- Oil: Engine oil can be hot and slippery. Wear gloves to protect your hands and prevent slipping.

- Valve Springs: Valve springs are under considerable tension. Use appropriate valve spring compressors to avoid injury. Releasing a valve spring improperly can cause serious harm.

Important Note: Before performing any repairs, consult your vehicle's service manual for specific instructions and safety precautions.

We have prepared a detailed diagram of the lifter system with labels and explanations. You can download this file [link to diagram file] to further enhance your understanding and aid in your repairs and projects.