What Are Rims Of A Car

Alright, let's dive into the often-overlooked but crucial component of your vehicle: the rims. Often casually referred to as "wheels," understanding what rims *actually* are, their function, and key specifications can empower you to make informed decisions about maintenance, upgrades, and even diagnosing potential problems. We're not just talking aesthetics here; we're talking about a critical link between your tires and the road.

Purpose: Why Bother Understanding Rims?

You might be thinking, "I just need them to hold the tire." While that's fundamentally true, a deeper understanding of rims is invaluable for several reasons:

- Maintenance & Repair: Identifying damage, understanding wear patterns, and knowing when a rim needs repair or replacement can save you money and prevent accidents.

- Upgrades & Customization: Choosing the right rims can dramatically improve your vehicle's handling, performance, and appearance. But you need to know your specs!

- Troubleshooting: Understanding rim-related issues can help you diagnose vibration problems, tire wear, and even suspension issues.

- Safety: A damaged or improperly installed rim can be a serious safety hazard. Knowing what to look for is crucial.

This article acts as a detailed guide to help you navigate the complexities of automotive rims. Let's get started.

Key Specs and Main Parts of a Rim

Let's break down the anatomy of a typical automotive rim and the key specifications you need to be aware of:

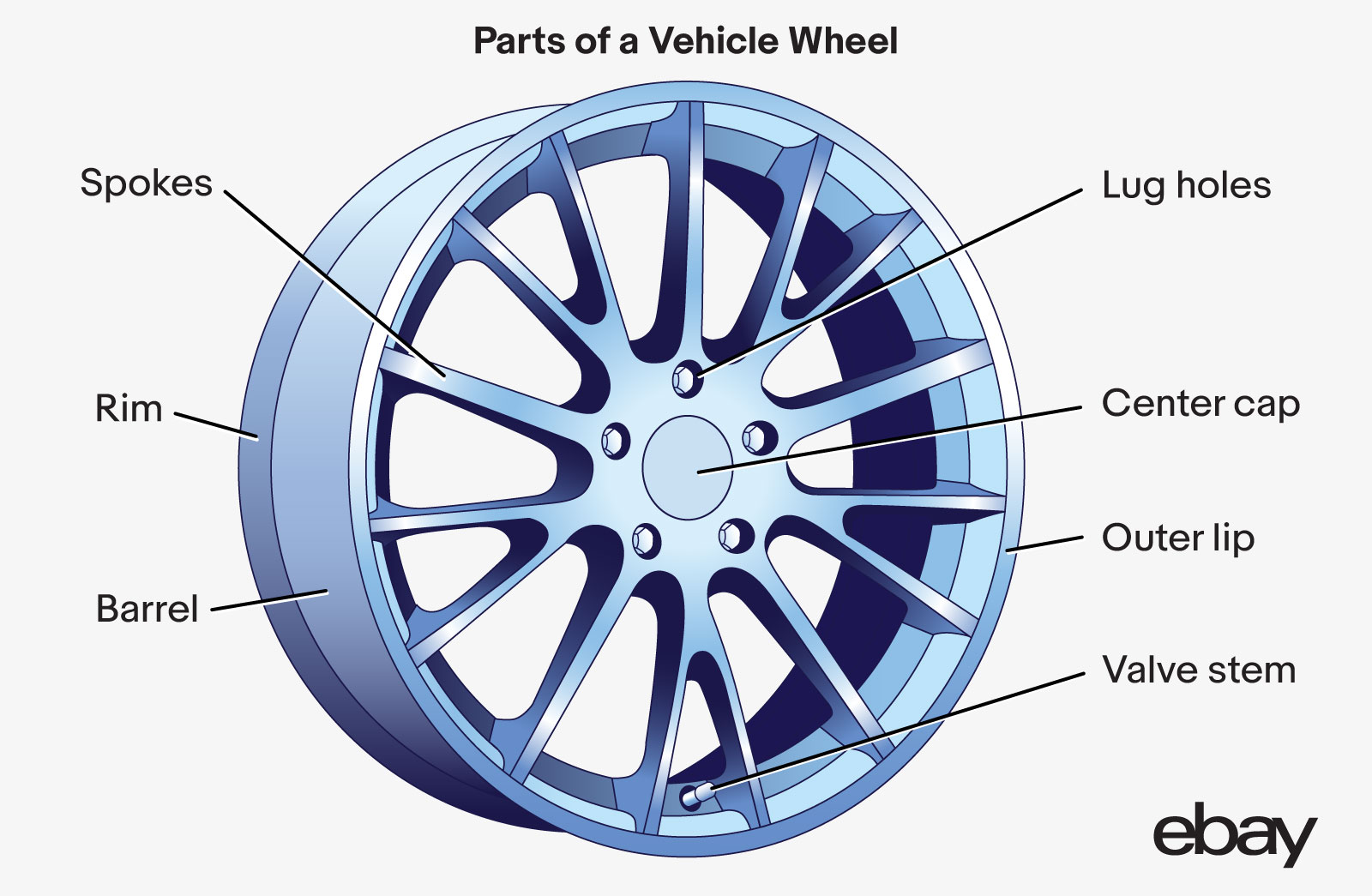

Main Parts:

- Rim Body (or Barrel): This is the main cylindrical part of the wheel that provides the structural support and connects to the wheel's center.

- Wheel Center (or Hub): This is the central part of the wheel that attaches directly to the vehicle's hub assembly via lug nuts or bolts.

- Spokes (if applicable): In some wheel designs, spokes radiate outward from the center to the rim body, providing strength and contributing to the wheel's aesthetic. Not all rims have spokes; some are solid disc designs.

- Drop Center: A recessed area on the inside of the rim. This helps during tire mounting and dismounting. It allows the tire bead to be pushed towards the center of the rim, providing slack for the other side of the tire to clear the rim flange.

- Rim Flange: The outer edge of the rim that holds the tire bead securely in place.

- Valve Stem Hole: The opening where the tire valve stem is installed for inflating the tire.

Key Specs:

- Diameter: Measured in inches, this is the overall diameter of the rim where the tire bead sits. This *must* match the tire's designated rim diameter. Mismatched diameters are a major safety hazard.

- Width: Measured in inches, this is the distance between the inner flanges of the rim. This also *must* be compatible with the tire's specified rim width range.

- Bolt Pattern (or Lug Pattern): This describes the number of lug nuts/bolts and the diameter of the circle they form. It's expressed as "number of lugs x bolt circle diameter" (e.g., 5x114.3mm). Getting this wrong means the wheel won't bolt onto the hub.

- Offset: Measured in millimeters, this is the distance between the wheel's mounting surface (where it contacts the hub) and the centerline of the wheel. Positive offset means the mounting surface is closer to the outside of the wheel, while negative offset means it's closer to the inside. Zero offset means the mounting surface is exactly on the centerline. Offset affects wheel fitment, scrub radius, and suspension geometry. Incorrect offset can lead to rubbing, handling issues, and premature wear of suspension components.

- Center Bore: The diameter of the hole in the center of the wheel that centers it on the hub. Some vehicles use hub-centric wheels, where the center bore precisely matches the hub diameter for optimal centering and load distribution. Others use lug-centric wheels, which rely solely on the lug nuts/bolts for centering.

- Load Rating: The maximum weight each wheel is designed to safely support. Exceeding this rating is extremely dangerous.

Think of these specs as ingredients in a recipe. If you get the proportions wrong, the dish (or in this case, your vehicle's handling and safety) won't turn out right.

How It Works

The rim's primary function is to provide a secure and airtight mounting surface for the tire. When the tire is inflated, the air pressure forces the tire beads against the rim flanges, creating a seal. The rim then transmits the forces generated by acceleration, braking, and turning from the tire to the vehicle's hub and ultimately the suspension system.

The rim also plays a role in heat dissipation from the brakes. The design and material of the rim can affect how effectively heat is transferred away from the braking system. Some high-performance rims are specifically designed with features to enhance brake cooling.

Real-World Use – Basic Troubleshooting Tips

Here are some common issues you might encounter with your rims and how to troubleshoot them:

- Vibration: Vibration can be caused by a bent rim, an unbalanced tire, or loose lug nuts. Start by checking your tire pressure and tightening the lug nuts to the correct torque. If the vibration persists, have your tires balanced and inspect the rims for damage. A dial indicator can be used to accurately measure runout (out-of-roundness) of the rim.

- Air Leakage: A slow leak can indicate a damaged rim, a faulty valve stem, or a poor seal between the tire and the rim. Inspect the valve stem for cracks and tighten the valve core. If the leak persists, have a tire shop inspect the rim for damage and reseat the tire.

- Visual Damage: Dents, cracks, and bends can compromise the structural integrity of the rim. If you notice any significant damage, have the rim inspected by a professional. Small scratches and cosmetic damage can be repaired, but structural damage often necessitates replacement.

- Uneven Tire Wear: While uneven tire wear is often related to alignment or suspension issues, it can sometimes be exacerbated by a damaged or improperly sized rim. Make sure your rims are the correct size and offset for your vehicle.

Remember: Always prioritize safety when working on your vehicle. If you're not comfortable performing a particular task, seek the help of a qualified mechanic.

Safety – Risky Components

Several components of the rim and wheel assembly are critical for safety:

- Rim Structure: As mentioned before, cracks, bends, or significant dents can severely compromise the structural integrity of the rim, leading to catastrophic failure.

- Lug Nuts/Bolts: Overtightening can stretch or break the studs or bolts. Undertightening can cause the wheel to come loose. Always use a torque wrench and tighten to the manufacturer's specified torque. Use the correct lug nut type for your wheels (conical, ball seat, flat seat).

- Tire Bead Seal: A poor seal between the tire and the rim can lead to sudden tire deflation, which is extremely dangerous, especially at high speeds.

- Valve Stem: A damaged or leaking valve stem can cause a slow leak, which can eventually lead to a flat tire.

A catastrophic rim failure can result in loss of control and a serious accident. Don't take chances with damaged or improperly installed rims.

By understanding the structure and specification of the car rims, you can not only keep your car wheels in the best condition, but also choose the most appropriate wheels based on the car and driving habit.