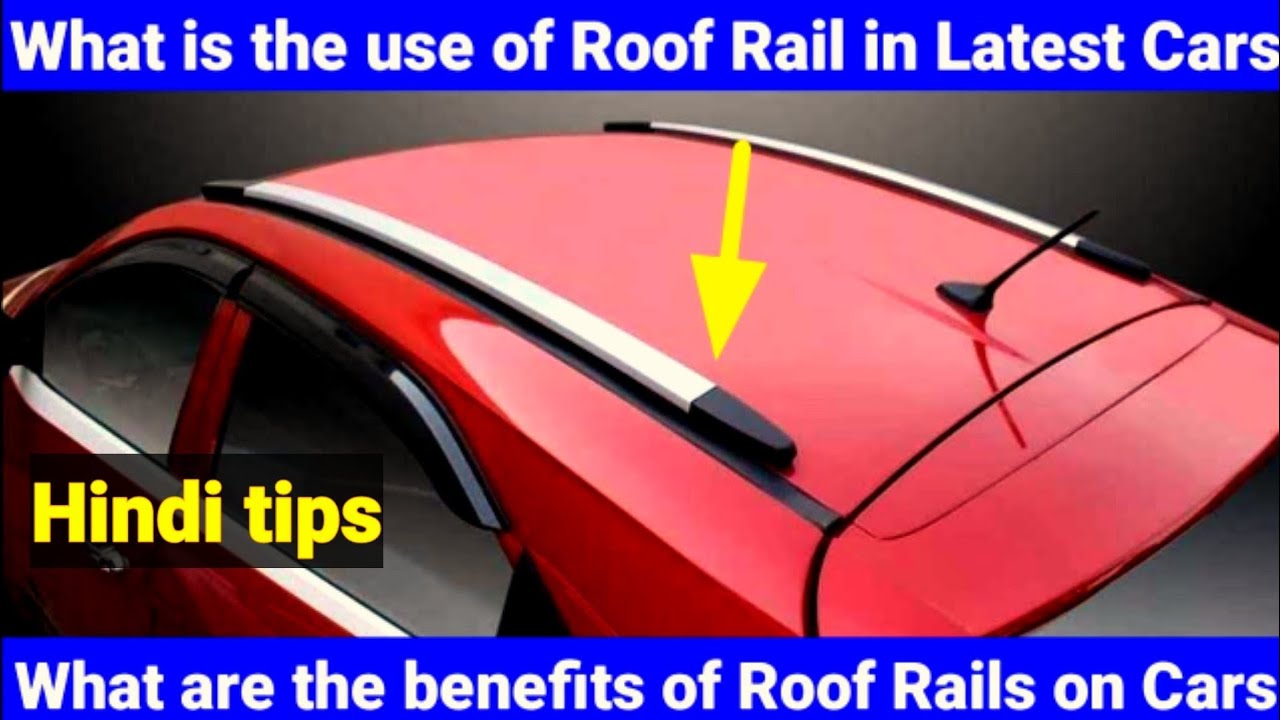

What Are Roof Rails Used For

Okay, let's dive into roof rails – those often-overlooked but incredibly useful features on many vehicles. As an experienced DIYer, understanding roof rails opens up a world of possibilities for cargo carrying, recreational equipment transport, and even vehicle modification. This article will break down the anatomy of roof rails, how they work, their limitations, and safety considerations.

Purpose of Understanding Roof Rails

Understanding roof rails is crucial for several reasons:

- Cargo Management: Correctly utilizing roof rails allows you to safely and efficiently transport luggage, sporting equipment, and other bulky items, freeing up space inside your vehicle.

- Vehicle Modification: For the modder, roof rails provide a solid foundation for mounting various accessories like light bars, awnings, or even specialized camping equipment.

- DIY Repairs & Maintenance: Knowing how roof rails are attached and the materials they're made from allows you to perform basic repairs or replacements yourself, saving on labor costs.

- Accident Prevention: Improperly loaded or secured cargo on roof rails can be a serious safety hazard. Understanding the load limits and proper tie-down techniques is essential.

Key Specs and Main Parts

Roof rails aren't just simple bars; they're engineered systems designed to withstand specific loads and environmental conditions. Here's a breakdown of the key components and specifications:

Main Parts:

- Rails (Longitudinal Bars): These are the primary bars that run along the length of the roof, typically made of aluminum or steel. They provide the main anchor points. Some are "flush" mounted close to the roof, others have a space below them.

- Towers/Mounts: These connect the rails to the vehicle's roof. The design varies depending on the vehicle and roof type. They are often bolted or riveted to reinforced areas of the roof.

- Crossbars: These attach perpendicularly to the rails and provide a surface for mounting cargo or accessories. They're usually sold separately.

- End Caps: These are protective covers for the ends of the rails, preventing water ingress and improving aerodynamics.

- Mounting Hardware: This includes bolts, screws, washers, and sometimes specialized brackets for attaching the rails to the roof.

Key Specs:

- Load Capacity: This is the maximum weight the roof rail system can safely carry. This is typically specified by the manufacturer and should never be exceeded. Overloading can damage the roof, rails, or even cause an accident. Look for this value in the owner's manual or on a sticker near the roof rails themselves. The load capacity also considers the weight of the rails and crossbars, so those weights needs to be subtracted from the total rating to arrive at the actual available cargo weight.

- Material: The material of the rails (aluminum or steel) affects its strength, weight, and corrosion resistance. Aluminum is lighter and more corrosion-resistant, while steel is stronger but heavier.

- Rail Profile: The shape of the rails influences the type of crossbars and accessories that can be attached. Common profiles include round, square, and aero. Aero profiles are designed to reduce wind noise and drag.

- Mounting Type: The way the rails are attached to the roof varies. Common methods include direct bolting to reinforced points, clamping to existing roof edges (often for vehicles without factory-installed rails), and adhesive bonding (less common for aftermarket installations).

How It Works

Roof rails function as a structural framework for carrying cargo. The rails themselves are designed to distribute the weight evenly across the roof structure. The towers/mounts transfer the load from the rails to the reinforced areas of the vehicle's roof. The crossbars then provide a stable platform for securing cargo or accessories.

The strength of the system depends on the materials used, the design of the mounts, and the way the rails are attached to the roof. Vehicle manufacturers reinforce specific areas of the roof to handle the added stress of carrying loads on the roof rails. This reinforcement is critical; attempting to attach roof rails to areas that are not reinforced can damage the roof structure and compromise the safety of the system.

Real-World Use - Basic Troubleshooting

Here are some common issues and troubleshooting tips for roof rails:

- Loose Rails: Regularly check the mounting hardware (bolts, screws) to ensure they are tight. Loose rails can vibrate, cause noise, and eventually detach. Use a torque wrench to tighten hardware to the manufacturer's specified torque.

- Corrosion: Inspect the rails and mounts for signs of corrosion, especially in areas exposed to salt or moisture. Clean and treat corroded areas to prevent further damage. Consider using anti-seize compound on fasteners during reassembly.

- Crossbar Compatibility: Ensure that the crossbars you use are compatible with the profile of your roof rails. Using incompatible crossbars can damage the rails or create an unsafe mounting situation. Check the manufacturer's specifications for crossbar compatibility.

- Water Leaks: If you notice water leaks inside your vehicle after installing or working on roof rails, check the seals around the mounting points. Damaged or improperly installed seals can allow water to enter the vehicle. Reseal the mounting points with appropriate sealant.

- Noise: Wind noise can be a common issue with roof rails, especially with certain crossbar designs. Using aerodynamic crossbars or adding wind fairings can help reduce noise.

Safety – Risky Components & Practices

Safety is paramount when dealing with roof rails. Here are some critical safety considerations:

- Overloading: Never exceed the load capacity of the roof rail system. Overloading can damage the roof, rails, and compromise vehicle stability. This is the most critical safety aspect.

- Improper Installation: Installing roof rails incorrectly can lead to structural failure and potential accidents. Follow the manufacturer's instructions carefully and use the correct hardware. If you are unsure about any aspect of the installation, consult a professional.

- Insecure Cargo: Always secure cargo properly to the crossbars using appropriate tie-down straps or ropes. Loose cargo can shift during transit, causing instability or even falling off the vehicle. Use ratchet straps with a sufficient working load limit (WLL).

- Roof Damage: Avoid drilling into the roof unless specifically instructed by the manufacturer and unless you are absolutely confident in your skills and knowledge. Improper drilling can weaken the roof structure and create a path for water leaks.

- Height Clearance: Be mindful of your vehicle's increased height when carrying cargo on the roof. Pay attention to overhead clearances in parking garages, tunnels, and low-hanging branches.

- Airbag Interference: Be aware of the placement of side curtain airbags. Mounting accessories too close to the airbag deployment path can interfere with their proper function in the event of an accident.

Symbols – Explained (if a diagram was included)

While we don't have a diagram to refer to directly in this document, here are some common symbols you might encounter in a roof rail diagram or installation manual:

- Torque Symbol (e.g., Nm, ft-lbs): Indicates the specified torque for tightening a bolt or screw.

- Arrow Symbols: Show the direction of movement or force.

- Wrench Symbol: Indicates the need for a wrench or specific tool.

- Warning Symbol (Triangle with Exclamation Point): Indicates a potential hazard or important safety instruction.

- Cutaway View: Reveals internal components or structures.

- Cross-Section View: Shows a side view of a component or assembly.

We have the diagram file available for download. It provides visual representation of the components discussed above and will aid in your understanding and potential repair projects. Safe travels!