What Are The Parts Of A Road

Hey there, fellow gearheads! Ever wonder what's *really* going on beneath your tires when you're cruising down the road? Beyond the obvious asphalt, there's a whole engineered system designed to support your vehicle, manage water runoff, and ensure a smooth (and safe!) ride. Understanding the anatomy of a road isn't just for civil engineers; it's incredibly useful for informed car owners, modders, and DIY mechanics. It empowers you to understand road conditions, potentially diagnose vehicle issues stemming from road damage, and even appreciate the complexity of infrastructure we often take for granted.

Why This "Road Map" Matters

Think of this as a diagram for the road *itself*. It’s not the electrical or mechanical diagram you're used to. Understanding the components that make up the road is crucial for several reasons:

- Problem Diagnosis: Bumps, potholes, and uneven surfaces can wreak havoc on your suspension, tires, and alignment. Knowing the layers beneath can help you identify potential root causes of vehicle problems.

- Informed Repairs: If you're dealing with a local council regarding road damage claims, understanding the standard road construction can help you formulate a better argument.

- Road Awareness: Recognizing signs of road degradation (like alligator cracking or rutting) can allow you to anticipate potential hazards and drive more defensively.

- Project Planning: If you're ever involved in a construction project near a road (e.g., landscaping or driveway installation), understanding the road structure will help you comply with regulations and avoid damaging it.

Key Specs and Main Parts

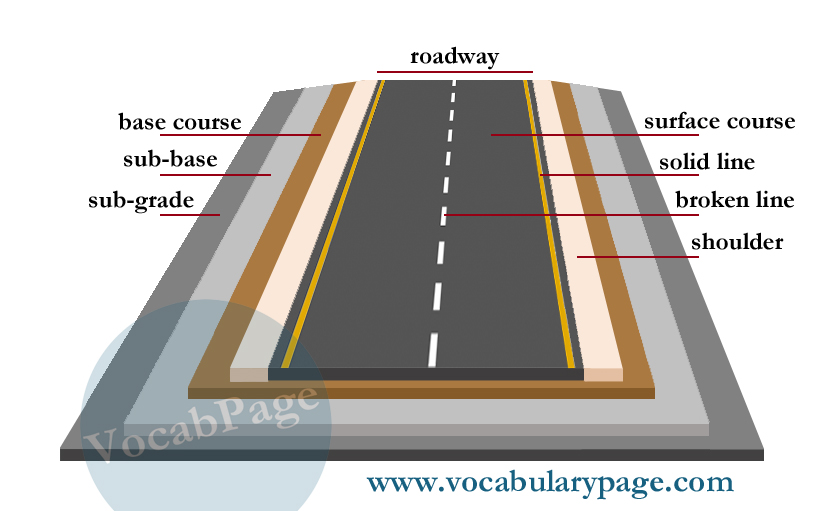

A typical road isn't just a layer of asphalt. It's a layered system, each layer contributing to the overall strength and durability. Here’s a breakdown of the essential parts, from top to bottom:

1. Surface Course (Wearing Course)

This is the topmost layer, the one your tires directly interact with. Its primary function is to provide a smooth, durable, and skid-resistant surface. Common materials include:

- Asphalt Concrete (AC): The most common, a mixture of asphalt binder and aggregates (crushed stone, gravel, sand). Different grades of asphalt are used depending on traffic volume and climate.

- Portland Cement Concrete (PCC): A mixture of cement, aggregates, and water, offering higher durability and longer lifespan than asphalt, but also more expensive. Often used in high-traffic areas or where heavy loads are expected.

- Surface Treatments: Chip seal (asphalt sprayed with aggregate), slurry seal (a thin mixture of asphalt emulsion and aggregate), and micro-surfacing (similar to slurry seal but with polymer-modified asphalt). These are used for preventative maintenance or to improve skid resistance.

Key Specs: Thickness typically ranges from 1.5 to 4 inches, depending on the material and traffic load. Skid resistance is measured using the International Friction Index (IFI).

2. Binder Course (Intermediate Course)

This layer provides a transition between the surface course and the base course. It is not always present but is often used on highways and roads with heavy traffic. It helps distribute loads and reduce stresses on the underlying layers.

- Asphalt Concrete (AC): Usually a coarser mix than the surface course, with larger aggregates.

Key Specs: Thickness varies, typically around 2-4 inches.

3. Base Course

This is the primary load-bearing layer. It distributes the weight of vehicles over a wider area, protecting the subgrade (the natural soil beneath). Common materials include:

- Crushed Stone: Angular, well-graded crushed rock. The interlocking nature of the angular aggregate provides excellent stability and load-bearing capacity.

- Gravel: Rounded rock fragments, often mixed with sand and silt. Less stable than crushed stone but more cost-effective.

- Stabilized Base: Crushed stone or gravel mixed with a stabilizing agent like cement, asphalt, or lime. This improves strength, durability, and resistance to moisture damage.

Key Specs: Thickness ranges from 4 to 12 inches or more, depending on the subgrade strength and traffic load. California Bearing Ratio (CBR) is a common test to determine the load-bearing capacity of the base course.

4. Subbase Course (Optional)

This layer is placed between the base course and the subgrade. It provides additional support, improves drainage, and prevents the migration of fine-grained soil particles from the subgrade into the base course. Often used in areas with poor subgrade conditions.

- Gravel: Often a coarser gravel than used in the base course.

- Sand: Used to improve drainage.

- Geotextile: A fabric layer used to separate the base course and subgrade, preventing mixing and improving drainage.

Key Specs: Thickness varies depending on subgrade conditions.

5. Subgrade

This is the natural soil that underlies the entire road structure. Its strength and stability are critical to the performance of the road. The subgrade may need to be compacted or stabilized to improve its load-bearing capacity. Common subgrade materials include clay, silt, sand, and gravel. The subgrade is almost never changed, it is the in situ soil.

Key Specs: The California Bearing Ratio (CBR) is also used to evaluate the subgrade strength.

Other Important Components

- Drainage Systems: Ditches, culverts, and subsurface drains are essential for removing water from the road structure and preventing damage from moisture.

- Shoulders: The area on either side of the travel lanes, providing space for emergency stopping, maintenance, and future widening.

- Road Markings: Paint, thermoplastic, or raised pavement markers used to delineate lanes, indicate traffic direction, and provide warnings.

Symbols – Lines, Colors, and Icons

While there isn't a universally standardized set of symbols for road diagrams (unlike electrical schematics), certain conventions are common:

- Layer Representation: Each layer is typically represented by a distinct solid color or a shaded area. Darker colors are often used for the upper layers (surface and binder courses) and lighter colors for the lower layers (base and subbase).

- Material Indication: Text labels are used to identify the material composition of each layer (e.g., "Asphalt Concrete," "Crushed Stone," "Clay").

- Arrows: Arrows may be used to indicate the direction of water flow in drainage systems.

- Hatching: Hatching patterns are sometimes used to differentiate between different types of materials within the same layer (e.g., different types of asphalt concrete).

How It Works

The road works as a system to distribute the stresses caused by vehicles. Each layer contributes to this process. The surface course takes the brunt of the wear and tear and provides the necessary friction. The binder course links the surface course and the base course. The base course, the main load-bearing layer, spreads the load over a wider area, reducing the stress on the subgrade. The subbase (if present) provides further support and drainage. Finally, the subgrade provides the foundation upon which the entire structure rests.

Effective drainage is crucial. Water infiltrating the road structure can weaken the materials, leading to premature failure. Drainage systems remove water, preventing this damage and extending the road's lifespan.

Real-World Use – Basic Troubleshooting Tips

Here are a few basic troubleshooting tips related to road conditions and their potential impact on your vehicle:

- Potholes: These indicate a failure in the surface course and potentially underlying layers. Driving through potholes can damage tires, wheels, suspension components, and alignment.

- Alligator Cracking: A network of interconnected cracks resembling alligator skin. This indicates structural failure, often due to a weakened base course or subgrade. Can lead to further deterioration and potholes.

- Rutting: Longitudinal depressions in the wheel paths. Caused by repeated traffic loading and can be exacerbated by water infiltration. Can lead to hydroplaning and reduced vehicle control.

- Bleeding: Excess asphalt binder on the surface, creating a shiny, sticky surface. Can reduce skid resistance and make the road slippery.

- Uneven Shoulders: Can make it difficult to safely pull over in an emergency.

If you notice any of these conditions, it's essential to drive cautiously and report them to the relevant authorities (e.g., local council or transportation department).

Safety – Highlight Risky Components

While the road itself isn't inherently "dangerous," certain components and conditions can pose risks:

- Potholes and Uneven Surfaces: These can cause loss of vehicle control, tire blowouts, and damage to suspension components.

- Slippery Surfaces: Bleeding asphalt or icy conditions can significantly reduce skid resistance, increasing the risk of accidents.

- Poor Drainage: Standing water on the road surface can lead to hydroplaning.

- Construction Zones: These often involve uneven surfaces, temporary lane closures, and reduced speed limits. Always be aware, reduce speed, and follow all traffic control devices.

Remember to always drive defensively and adjust your speed and driving style to match the road conditions. Regular vehicle maintenance, especially tire pressure checks and suspension inspections, can also help you mitigate the risks associated with poor road conditions.