What Awd Means In A Car

Alright, let's dive into the nuts and bolts of All-Wheel Drive, or AWD. As a seasoned DIYer, understanding your car's drivetrain is crucial for everything from basic maintenance to advanced modifications. This article breaks down what AWD means in a car, covering its purpose, key components, how it works, and some practical troubleshooting tips.

Purpose – Why Understanding AWD Matters

Why bother learning about AWD? Well, knowledge is power, especially when it comes to your car. Understanding your AWD system allows you to:

- Diagnose Problems Accurately: Knowing the components and how they interact means you can pinpoint issues faster and avoid unnecessary repairs.

- Perform Maintenance Effectively: You'll understand what fluids need changing and when, maximizing the lifespan of your AWD system.

- Make Informed Modification Decisions: Planning to upgrade your suspension or tires? Understanding how AWD affects handling is critical.

- Avoid Costly Mistakes: Attempting repairs without proper knowledge can lead to expensive damage.

Key Specs and Main Parts of an AWD System

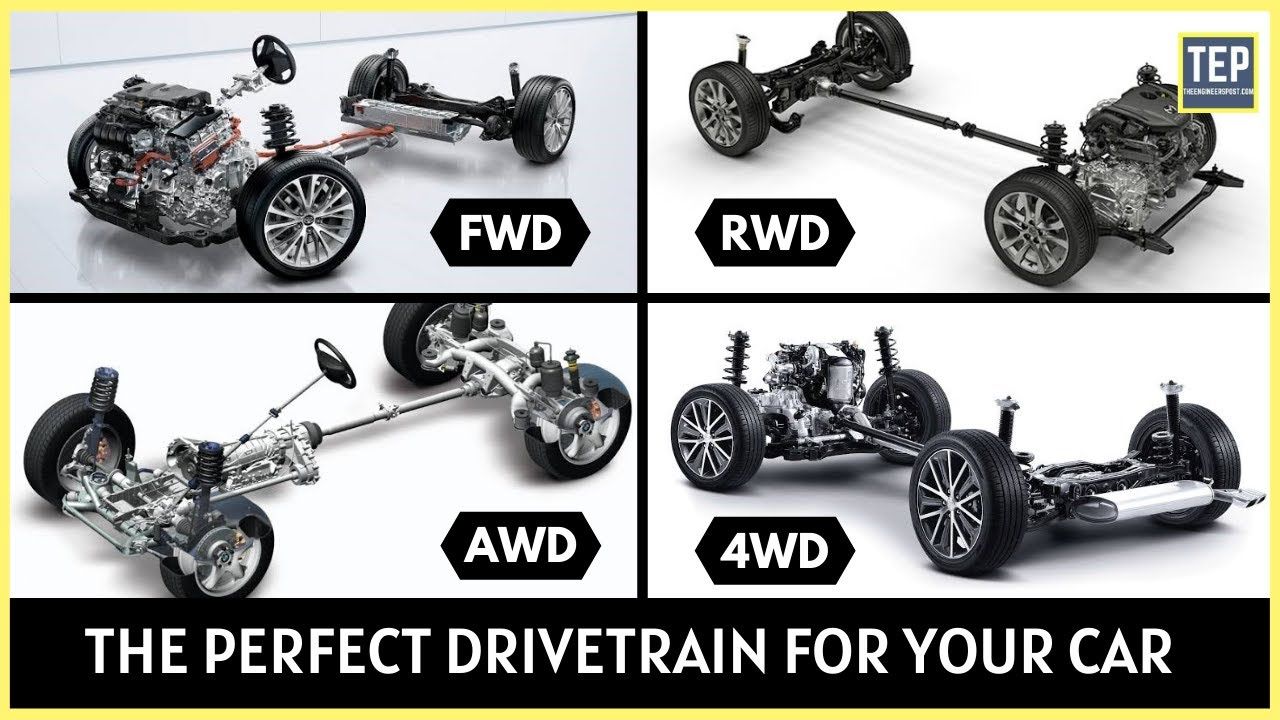

AWD systems aren't all created equal. They vary significantly in their design and performance. Let's cover the main types and components:

Types of AWD Systems:

- Part-Time AWD: Typically found in older trucks and SUVs. The driver manually engages AWD, locking the front and rear axles together. Not suitable for on-pavement driving because it can cause driveline binding.

- Full-Time AWD: Often uses a center differential or viscous coupling to distribute power between the front and rear axles. Allows for on-pavement driving in AWD.

- Automatic AWD: Engages automatically when the system detects wheel slip. Often uses electronically controlled clutches or couplings to transfer power.

Main Components:

- Engine: The source of power.

- Transmission: Transfers power from the engine to the drivetrain.

- Transfer Case (or Power Transfer Unit - PTU): This is a crucial component in most AWD systems. It splits the power from the transmission and sends it to both the front and rear axles. A PTU is generally lighter and less robust than a transfer case and often found on crossover vehicles.

- Front Differential: Allows the front wheels to rotate at different speeds when turning.

- Rear Differential: Allows the rear wheels to rotate at different speeds when turning.

- Drive Shafts (or Propeller Shafts): Connect the transfer case to the front and rear differentials.

- Axle Shafts: Connect the differentials to the wheels.

- Electronic Control Unit (ECU) & Sensors: Modern AWD systems often use sensors (wheel speed sensors, throttle position sensor, etc.) and an ECU to monitor driving conditions and adjust power distribution accordingly.

- Couplings/Clutches (Viscous Coupling, Haldex Clutch, etc.): These are used in automatic and some full-time AWD systems to control the amount of power sent to the front or rear axles.

How It Works: Power Distribution

The core function of an AWD system is to distribute engine power to all four wheels. How it does this depends on the type of system.

In a part-time AWD system, when engaged, the transfer case mechanically locks the front and rear drive shafts together. This forces the front and rear axles to rotate at the same speed. While simple, this system is only suitable for low-traction surfaces. Using it on dry pavement can damage the drivetrain.

Full-time AWD systems use a center differential to allow for different front and rear axle speeds. The center differential can be a mechanical differential, a viscous coupling, or an electronically controlled clutch. A mechanical differential allows a set percentage of torque to the front and rear axle and allows for slippage between the axles. A viscous coupling uses a fluid that becomes more solid as the difference in speed between the axles increases, thus transferring more torque to the axle with better traction. Electronically controlled clutches can vary the amount of torque sent to each axle based on sensor data.

Automatic AWD systems typically operate in two-wheel drive under normal conditions. When the system detects wheel slip (e.g., through wheel speed sensors), it engages the AWD system, often using an electronically controlled clutch to transfer power to the axle with more traction. The Haldex system is a common example of this. It's an on-demand system that biases power towards the front wheels until slippage is detected.

Real-World Use: Basic Troubleshooting Tips

Here are a few basic troubleshooting tips for your AWD system:

- Unusual Noises: Grinding, clunking, or whining noises can indicate problems with the transfer case, differentials, or drive shafts.

- Vibrations: Excessive vibrations, especially at certain speeds, could point to a worn U-joint, unbalanced drive shaft, or damaged CV joint.

- AWD Light Illumination: If the AWD warning light comes on, there's a fault in the system. Have it diagnosed using a scan tool.

- Fluid Leaks: Check the transfer case and differentials for leaks. Low fluid levels can lead to serious damage. Regular fluid changes are crucial.

- Wheel Speed Sensor Issues: A faulty wheel speed sensor can disable the AWD system in some vehicles. These often trigger an ABS or Traction Control light as well.

Safety – Highlight Risky Components

Working on an AWD system involves handling some potentially dangerous components:

- High-Pressure Fluids: Some AWD systems use hydraulic clutches or couplings. Be careful when disconnecting hydraulic lines.

- Heavy Components: Transfer cases, differentials, and drive shafts are heavy. Use proper lifting equipment and techniques to avoid injury.

- Rotating Parts: Always disconnect the battery before working on the drivetrain to prevent accidental engagement.

- Jacking and Support: Ensure the vehicle is properly supported on jack stands before working underneath. Never rely solely on a jack.

Driveline Binding: As mentioned before, using part-time AWD on high-traction surfaces can cause driveline binding, which puts stress on the drivetrain components and can lead to damage. Always disengage part-time AWD when driving on pavement.

Proper Torquing: When reassembling any drivetrain components, it's crucial to use a torque wrench and follow the manufacturer's specifications. Overtightening or undertightening bolts can lead to leaks or component failure.

Understanding your AWD system empowers you to maintain, troubleshoot, and even modify your vehicle with confidence. Don't be afraid to get your hands dirty, but always prioritize safety and consult the service manual for specific procedures.

We have a detailed AWD system diagram available for download. This diagram visually represents the components discussed above and their interconnections. Having this at your disposal will greatly enhance your understanding and ability to work on your AWD system effectively.