What Car Has A 5x115 Bolt Pattern

Alright, let's talk about the 5x115 bolt pattern. This is a pretty common spec, but figuring out exactly *what* cars use it can sometimes feel like a treasure hunt. Knowing this information is crucial for several reasons, whether you're swapping wheels for aesthetics, replacing damaged rims, or just trying to ensure you're buying the right parts. This article will give you the inside scoop.

Why This Bolt Pattern Information Matters

Understanding bolt patterns is fundamental for several reasons:

- Wheel Replacement & Upgrades: The most obvious reason. Incorrect bolt patterns mean the wheel simply won't mount. You'll be left with a useless wheel and wasted money.

- Proper Fitment & Safety: Even if you *force* a wheel on with the wrong bolt pattern (don't do this!), you create an incredibly dangerous situation. Uneven pressure on the studs can lead to stud failure, wheel separation, and catastrophic accidents.

- Repair & Maintenance: When replacing damaged wheels, you *must* know the correct bolt pattern to order the right replacements.

- Learning & Understanding: As a DIYer, understanding these specifications allows you to be more informed about your vehicle and make better decisions regarding its care and modification.

Key Specs and Main Parts Involved

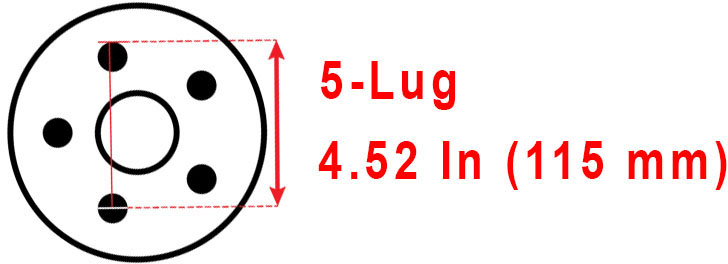

Let's break down the specifics of a 5x115 bolt pattern:

- "5" - Number of Lugs: This indicates the wheel has five lug holes (the holes through which the lug nuts/bolts pass).

- "115" - Bolt Circle Diameter (BCD): This is the diameter of the circle that passes through the center of each of the five lug holes. It's measured in millimeters (mm). This is sometimes incorrectly reported as 4.53" (which is a close, but not precise, inch equivalent). Precision matters here.

- Center Bore: This is the diameter of the hole in the center of the wheel. It's critical for proper centering on the hub. While not directly part of the bolt pattern, it’s essential for proper wheel fitment. Some wheels may have a larger center bore and require hub-centric rings to properly center on the vehicle's hub.

- Offset: The offset is the distance between the wheel's mounting surface and its center line. Measured in millimeters (mm) and crucial for proper clearance from brakes, suspension, and body panels. A wrong offset can cause rubbing or interference.

- Lug Nuts/Bolts: These fasten the wheel to the hub. They come in various styles (conical, ball seat, flat seat) and thread sizes. Using the correct lug nut/bolt for your wheel is *critical* for safety.

Main Parts:

- Wheel Hub: The central part of the wheel assembly that rotates. It's where the wheel mounts and where the bearings reside.

- Wheel Studs: These are threaded bolts pressed into the hub. The lug nuts thread onto these studs to secure the wheel. (Some vehicles use wheel bolts that thread directly into the hub).

- Lug Nuts/Bolts: As mentioned before, these are the fasteners.

What Cars Use a 5x115 Bolt Pattern?

This is where things get a bit tricky. The 5x115 bolt pattern is primarily associated with certain American manufacturers, particularly Chrysler, Dodge, and some GM models. However, it's important to verify the bolt pattern for *your specific year and trim* as manufacturers sometimes change bolt patterns even within the same model line. A wheel fitment guide or an online database is your friend here. Here are some examples, but *always verify*:

- Chrysler: Some Chrysler 300 models (especially older ones), Chrysler Concorde, Chrysler LHS.

- Dodge: Some Dodge Charger models (again, often older ones), Dodge Magnum, Dodge Intrepid.

- Buick: Some Buick Park Avenue and Buick Riviera models.

- Pontiac: Some Pontiac Bonneville models.

- Cadillac: Some Cadillac DeVille and Cadillac Seville models.

Important Note: There's a similar bolt pattern – 5x114.3mm (or 5x4.5 inches) – that's *very close* to 5x115mm. While some might try to force the fit, this is generally not recommended due to potential stress on the wheel studs and hub. Always double-check your measurements!

How It Works: The Physics of Wheel Mounting

The lug nuts (or bolts) clamp the wheel to the hub via friction. When properly torqued, the clamping force is immense. The conical (or ball or flat) shape of the lug nut/bolt and the corresponding seat on the wheel are designed to evenly distribute this clamping force. This even distribution is critical. If the bolt pattern is incorrect, the clamping force won't be even, potentially leading to:

- Stud Failure: Uneven stress can cause studs to fatigue and eventually break.

- Wheel Loosening: The wheel may not be securely clamped, leading to it coming loose while driving.

- Vibration: An improperly mounted wheel will vibrate, which can be felt through the steering wheel and seats.

- Damage to the Hub: Over time, the uneven stress can damage the wheel hub itself.

Real-World Use: Basic Troubleshooting Tips

Here are some common problems and how to address them when dealing with wheel mounting:

- Vibration After Wheel Installation: This could indicate a loose lug nut, an improperly balanced wheel, or a bent wheel. Retorque the lug nuts to the manufacturer's specification. If the vibration persists, have the wheels balanced.

- Difficulty Tightening Lug Nuts: Check the threads on the studs and lug nuts for damage. Replace any damaged components. Also, ensure you're using the correct lug nut type (conical, ball, or flat).

- Lug Nuts Keep Loosening: This could be a sign of stretched studs or a worn hub. Replace the studs and/or hub as needed. Always use a torque wrench to tighten lug nuts to the correct specification.

- Wheel Doesn't Seat Properly: The bolt pattern is likely incorrect, or the center bore is too small. Double-check the bolt pattern and center bore specifications. Don't force it!

Safety: Risky Components and Procedures

Working on wheels and tires can be dangerous if you don't take the proper precautions. Here are some key safety points:

- Always use jack stands: Never work under a vehicle supported only by a jack. This is non-negotiable.

- Use a torque wrench: Overtightening lug nuts can stretch the studs and damage the wheels. Undertightening can lead to the wheel coming loose. A torque wrench ensures proper and even tightening.

- Inspect lug nuts and studs: Look for signs of wear, damage, or corrosion. Replace any questionable components.

- Proper lifting points: Consult your vehicle's owner's manual for the correct jacking points. Using the wrong points can damage the vehicle.

- Wheel chocks: Always use wheel chocks on the wheels that are *not* being lifted to prevent the vehicle from rolling.

Working with wheels and tires is a relatively straightforward process, but it's crucial to understand the underlying principles and safety considerations. Knowing your car's bolt pattern, offset, and center bore is essential for ensuring proper fitment and safe operation.

Disclaimer: Wheel fitment can be complex and vary based on vehicle modifications and aftermarket parts. Always consult with a qualified professional or use a reputable fitment guide to ensure proper wheel selection.

We have a detailed diagram of the 5x115 bolt pattern available for download to help you visualize the measurements and components discussed. Feel free to use it as a reference during your wheel selection or repair process.