What Cars Are Front Wheel Drive

Understanding which cars utilize front-wheel drive (FWD) is crucial for anyone performing their own maintenance, modifications, or even just diagnosing issues. This article serves as a comprehensive guide to FWD systems, breaking down the components, operation, and troubleshooting techniques relevant to the experienced DIYer. We will cover the main parts and specifications, explaining how it all works together.

Why This Matters: The Importance of Understanding FWD

Many owners of front-wheel drive vehicles attempt repairs that don't go well, simply because they don't fully understand the system. A solid understanding of FWD allows you to accurately diagnose problems, perform maintenance correctly, and potentially save significant money on repairs. This is especially relevant when working on components like the transaxle, driveshafts, or suspension. Furthermore, knowing the nuances of FWD handling characteristics can improve your driving skills and safety. Modifying FWD vehicles effectively requires understanding how changes impact torque steer and overall vehicle dynamics.

Key Specs and Main Parts of a FWD System

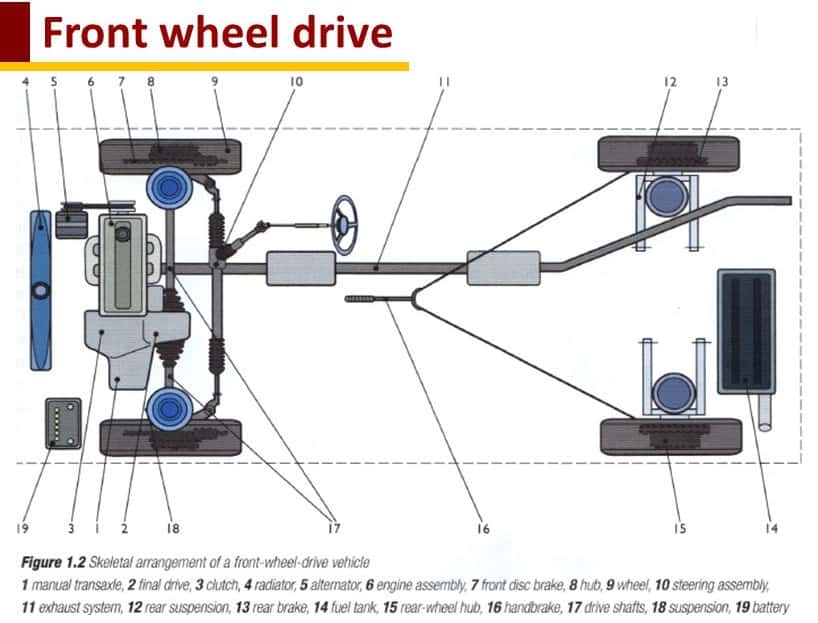

At its core, a FWD system combines the engine, transmission, and differential into a single unit, commonly referred to as a transaxle. This compact design helps reduce weight and complexity. Here’s a breakdown of the main components:

- Engine: The power source, generating torque that drives the wheels. Specifications to consider include horsepower, torque output (especially at different RPMs), and compression ratio.

- Transaxle: A combination of the transmission and differential.

- Transmission: Responsible for changing the gear ratio to optimize engine torque for different speeds and driving conditions. Types include manual transmissions (MT) and automatic transmissions (AT), each with its own specific construction and maintenance requirements.

- Differential: Allows the wheels to rotate at different speeds when cornering, preventing tire slippage and maintaining traction. In FWD applications, this is typically an open differential, though limited-slip differentials (LSDs) are available as aftermarket upgrades for enhanced performance.

- Driveshafts (or Half-shafts): Transmit power from the transaxle to the front wheels. They consist of two constant velocity (CV) joints connected by a shaft.

- CV Joints: Allow the driveshaft to articulate freely as the suspension moves and the wheels steer. They are packed with grease and protected by rubber boots.

- Hubs and Bearings: Connect the wheels to the suspension and allow them to rotate smoothly.

- Steering System: Allows the driver to control the direction of the wheels. This can be hydraulic power steering (HPS) or electric power steering (EPS), both of which connect to the steering knuckles.

- Suspension System: Absorbs bumps and maintains tire contact with the road. Front suspension in FWD cars is typically MacPherson strut or double wishbone designs.

Key Specifications: When working on a FWD system, pay close attention to the following:

- Torque specifications: Critical for fasteners on components like driveshafts, hubs, and suspension parts. Improper torque can lead to component failure.

- Fluid types: Using the correct transmission fluid (ATF or MTF) is essential for longevity. Always consult the vehicle's service manual.

- CV joint grease: Specific types of grease are required for CV joints to ensure proper lubrication and prevent premature wear.

How a FWD System Works

The process begins with the engine producing torque. This torque is then transmitted to the transaxle. Inside the transaxle, the transmission selects the appropriate gear ratio based on the driver's input and vehicle speed. The selected gear ratio multiplies the engine torque, delivering the necessary power to the wheels. From the transmission, power flows to the differential. The differential splits the torque between the two front wheels, allowing them to rotate at different speeds during turns. Finally, the driveshafts transfer the torque from the differential to the front wheels, propelling the vehicle forward.

One of the critical elements in FWD is the CV joint. It is designed to transmit torque through a variable angle, therefore accommodating both suspension travel and steering movements. Without CV joints, the driveshaft would bind and break as the wheels move. The CV joint boots are crucial for protecting the joint from dirt and water. If a boot tears, the joint will quickly become contaminated and fail.

Real-World Use: Basic Troubleshooting Tips

Here are some common FWD-related issues and troubleshooting tips:

- Clicking or popping sound during turns: This is a classic symptom of worn or damaged CV joints. Inspect the CV joint boots for tears or leaks. If the boot is intact, the joint itself may be worn internally. Replacement of the driveshaft is often the best course of action.

- Vibrations during acceleration: Can indicate worn CV joints, an unbalanced driveshaft, or even issues within the transaxle. Start by inspecting the CV joints.

- Fluid leaks from the transaxle: Inspect the seals around the driveshaft outputs and the transmission case. Low fluid levels can cause shifting problems and internal damage.

- Difficulty shifting gears (manual transmission): Could be caused by worn clutch components, low transmission fluid, or damaged shift linkage.

- Harsh or erratic shifting (automatic transmission): Often indicates low transmission fluid, contaminated fluid, or internal transmission problems. A transmission flush and fluid change can sometimes resolve minor issues.

- Torque steer (excessive pulling to one side during acceleration): This is an inherent characteristic of FWD vehicles, but excessive torque steer can indicate uneven tire wear, suspension problems, or a faulty differential.

Safety: Highlight Risky Components

Working on a FWD system involves inherent risks. Always disconnect the negative battery cable before starting any work.

Transaxle: Be extremely cautious when working with the transaxle. It's heavy and can cause serious injury if dropped. Use a transmission jack to support the transaxle during removal and installation.

Springs: The coil springs in the front suspension store a significant amount of energy. Never attempt to disassemble a MacPherson strut without using a proper spring compressor. Improper spring compression can result in serious injury or death.

Driveshafts: Avoid exposing CV joints to dirt or debris. Always replace a damaged CV joint boot immediately.

Hydraulic Systems: When dealing with hydraulic power steering (HPS) be mindful of the high-pressure fluid. Depressurize the system before disconnecting any lines.

Additional Resources

For more in-depth information and detailed diagrams, consult your vehicle's service manual. Numerous online forums and communities cater to DIY mechanics, providing valuable insights and assistance.

We have a detailed exploded diagram of a typical FWD system. You can download it here. This diagram will help you visualize the relationship between the different components and aid in your troubleshooting and repair efforts. Good luck!