What Cars Are Rear Wheel Drive

Alright, let's dive into the world of rear-wheel drive (RWD) vehicles. This is a fundamental concept in automotive engineering, and understanding it is crucial whether you're planning on modifying your ride, performing maintenance, or simply want a deeper understanding of how your car operates. This article breaks down the workings of a RWD system, highlighting its key components, operation, and practical considerations. We've also got a detailed schematic available for download – more on that later.

Purpose of Understanding Rear-Wheel Drive

Why bother understanding RWD? Well, several reasons. First, if you own a RWD car, knowing the system intimately will help you diagnose problems faster and more accurately. Are you experiencing wheel spin? Does your car handle differently in wet conditions? Knowing how power is transferred from the engine to the rear wheels gives you insights into the potential causes. Second, understanding RWD is essential for any performance modifications. Upgrading engine power without addressing the drivetrain can lead to component failures. Understanding the limitations of the rear axle, differential, and driveshaft is key to building a reliable and high-performing machine. Finally, and perhaps most importantly, a solid understanding of your car's driveline enhances your ability to perform safe and effective repairs.

Key Specs and Main Parts of a RWD System

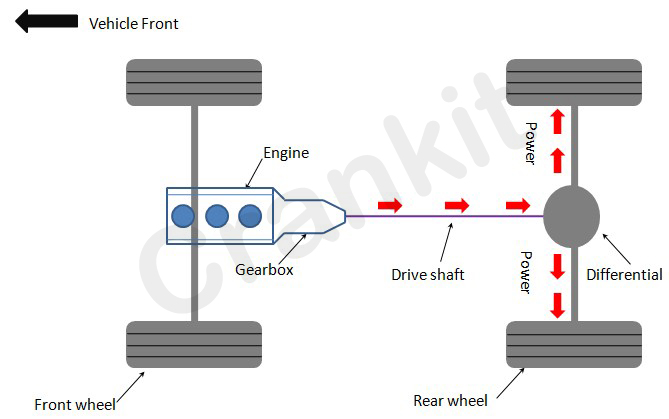

A typical RWD system comprises the following core components:

1. Engine

The engine, of course, generates the power. It's the source of all motion in the vehicle.

2. Transmission

The transmission is a gear-shifting device that matches engine speed and torque to the road speed. It allows the engine to operate within its optimal RPM range while providing the necessary torque to the wheels. Transmissions can be manual or automatic, both serving the same basic function.

3. Driveshaft

The driveshaft (or propshaft) is a rotating shaft that transmits torque from the transmission to the rear axle. It’s a critical component as it bridges the gap between the transmission, often located in the front of the vehicle, and the differential in the rear. Driveshafts are typically made of steel or aluminum and are dynamically balanced to minimize vibrations, especially at high speeds. They feature universal joints (U-joints) or constant-velocity (CV) joints at each end to allow for angular movement as the suspension articulates.

4. Rear Axle/Differential

This is where the magic happens. The rear axle houses the differential, which is a complex assembly of gears designed to do two things: first, it takes the rotational force from the driveshaft and turns it 90 degrees to drive the rear wheels. Second, and more importantly, it allows the rear wheels to rotate at different speeds when the vehicle is turning. This is essential because the outside wheel travels a longer distance than the inside wheel during a turn. Without a differential, the wheels would bind and the car would be very difficult to steer. The differential is typically filled with gear oil to lubricate and cool the gears.

There are also different types of differentials, including:

- Open Differential: The most common type, allowing wheels to spin independently.

- Limited-Slip Differential (LSD): Limits the amount of wheel spin, providing better traction.

- Locking Differential: Locks the axles together, forcing both wheels to spin at the same speed, ideal for off-road conditions but not suited for regular street driving.

5. Axle Shafts

The axle shafts connect the differential to the wheels, transmitting the rotational force from the differential to the hubs and ultimately driving the wheels. They are robust steel shafts designed to withstand significant torque and stress.

Symbols Explained in a Typical RWD Diagram

When you examine a RWD diagram, you'll encounter a variety of symbols representing the different components and connections. Here’s a breakdown:

- Solid Lines: Typically represent mechanical connections, such as the driveshaft or axle shafts.

- Dashed Lines: Often indicate control lines, such as vacuum lines or electrical wiring related to the transmission or differential locking mechanisms.

- Gear Symbols: These depict the gears within the transmission and differential. Different gear sizes and arrangements indicate gear ratios.

- Bearing Symbols: Bearings are represented by circles or rollers, indicating points of rotational support.

- Arrow Symbols: Arrows generally show the direction of rotational force or fluid flow.

- Color Coding: Many diagrams use color to differentiate between components or systems. For example, oil passages might be colored blue, while electrical wiring might be colored according to the standard electrical code (red for power, black for ground, etc.).

How It Works: The Power Flow

Here's a step-by-step breakdown of how a RWD system delivers power to the rear wheels:

- The engine generates power through combustion.

- The power is transmitted to the transmission.

- The transmission selects the appropriate gear ratio, adjusting torque and speed.

- The driveshaft transmits the rotational force from the transmission to the differential.

- The differential splits the power and directs it to the axle shafts.

- The axle shafts rotate the rear wheels, propelling the vehicle forward.

Real-World Use: Basic Troubleshooting Tips

Here are a few common RWD issues and how to troubleshoot them:

- Excessive Wheel Spin: This can be caused by low traction (wet or icy roads), excessive throttle input, or a worn-out differential. If you have an open differential, one wheel might spin freely while the other remains stationary. Consider upgrading to a limited-slip differential for improved traction.

- Vibrations: Vibrations, especially at higher speeds, can indicate a problem with the driveshaft. Check for damaged U-joints, loose bolts, or an unbalanced driveshaft. A bent driveshaft can also cause vibrations and needs to be replaced.

- Clunking Noises: Clunking sounds from the rear axle can indicate worn-out U-joints, loose suspension components, or a problem with the differential. Inspect the U-joints for play and the differential for leaks.

- Differential Leaks: Check the differential housing for leaks. Low gear oil levels can lead to premature wear and failure of the differential. Regularly check and top off the gear oil as needed.

Safety: Highlight Risky Components

Working on a RWD system involves certain safety risks. Here are some key areas to be mindful of:

- Driveshaft: The driveshaft rotates at high speeds and can cause serious injury if it comes loose or breaks. Always ensure the vehicle is properly supported before working on the driveshaft. Never work under a vehicle supported only by a jack. Always use jack stands.

- Differential: The differential contains heavy gears and sharp edges. Use caution when handling the differential components. Gear oil can be slippery, so clean up any spills immediately.

- Springs: Rear suspension springs can store a significant amount of energy. Use spring compressors or other appropriate tools to safely compress and remove the springs.

- Exhaust: Be mindful of the exhaust system's proximity to the drivetrain. Exhaust components get extremely hot during operation and can cause severe burns. Allow the exhaust to cool completely before working near it.

Always disconnect the negative battery terminal before working on any electrical components. If you are not comfortable performing a specific task, seek the help of a qualified mechanic.

Remember to consult your vehicle's repair manual for specific instructions and torque specifications.

We have the RWD system diagram file available for you to download. This diagram provides a visual representation of the system's components and their relationships, which will be a valuable resource for your repairs and modifications.

By understanding the principles of RWD, you can enhance your ability to maintain, repair, and modify your vehicle. Remember to prioritize safety and consult reliable resources whenever you're unsure about a procedure.