What Causes An Engine To Miss

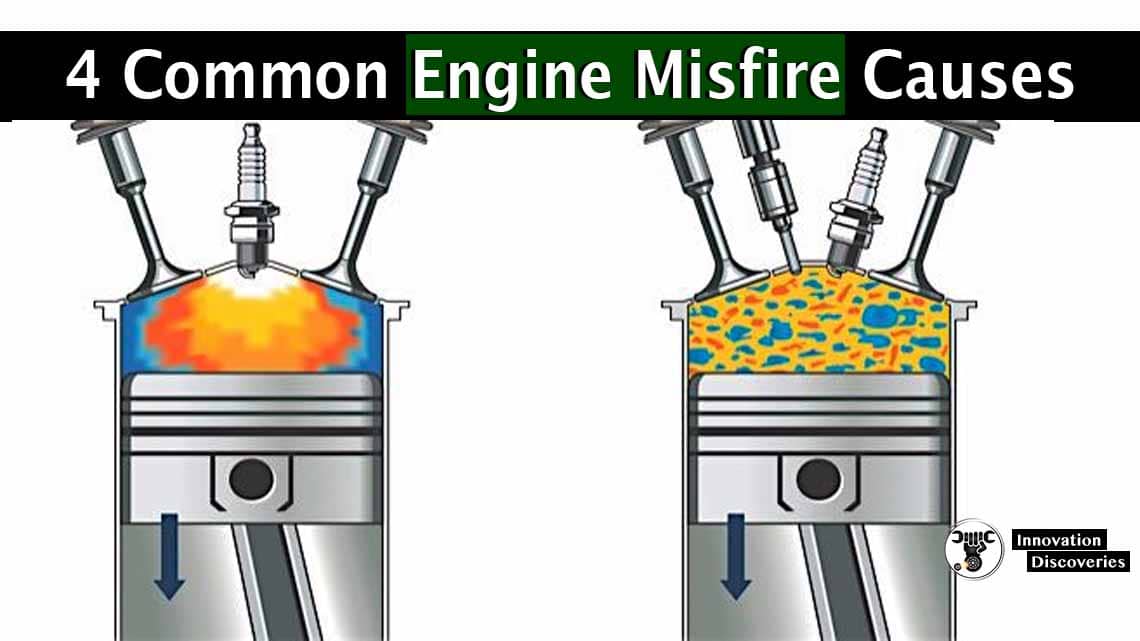

Alright, let's dive into what causes an engine to miss. A misfire, at its core, is a failure in the combustion process within one or more of your engine's cylinders. This results in incomplete or nonexistent burning of the air-fuel mixture, leading to rough running, loss of power, poor fuel economy, and potentially even damage to other engine components. Understanding why misfires happen is crucial, whether you're trying to diagnose a problem yourself or just want a better grasp of how your engine works.

Why Understanding Misfires Matters

Knowing the causes of engine misfires is essential for several reasons:

- Diagnosis and Repair: Pinpointing the root cause of a misfire allows for targeted repairs, saving you time and money. You won't be replacing parts unnecessarily.

- Preventative Maintenance: Recognizing the early signs of potential misfire causes lets you address them before they become major problems, preventing more costly repairs down the line.

- Performance Tuning: Understanding the factors influencing combustion is critical for optimizing engine performance, especially if you're modifying your vehicle.

- General Engine Knowledge: Simply put, it's good to know how your engine functions and what can go wrong.

The Combustion Quartet: Key Specs and Main Parts

For combustion to occur correctly, you need four things: air, fuel, compression, and spark. These elements are interdependent; a problem with any one can lead to a misfire.

1. Air Intake System

The air intake system draws air into the engine. Key components include:

- Air Filter: Cleans the incoming air, preventing debris from entering the engine.

- Throttle Body: Controls the amount of air entering the intake manifold.

- Intake Manifold: Distributes air to the cylinders.

- Mass Airflow (MAF) Sensor: Measures the amount of air entering the engine, providing data to the ECU. A faulty MAF sensor can cause incorrect air-fuel ratios.

- Manifold Absolute Pressure (MAP) Sensor: Measures the pressure in the intake manifold.

2. Fuel System

The fuel system delivers fuel to the cylinders. Key components include:

- Fuel Tank: Stores fuel.

- Fuel Pump: Supplies fuel under pressure to the fuel injectors.

- Fuel Filter: Cleans the fuel, preventing contaminants from clogging the injectors.

- Fuel Injectors: Spray fuel into the intake manifold or directly into the cylinder (in direct injection systems). Clogged or failing injectors are a common cause of misfires.

- Fuel Pressure Regulator: Maintains constant fuel pressure to the injectors.

3. Compression

Compression is essential to create the necessary pressure and temperature for combustion. Key components include:

- Pistons: Move up and down in the cylinders, compressing the air-fuel mixture.

- Piston Rings: Seal the gap between the pistons and cylinder walls, preventing compression loss.

- Cylinder Head: Forms the top of the combustion chamber and houses the valves.

- Valves (Intake and Exhaust): Control the flow of air and exhaust gases into and out of the cylinder. Valve train issues, like worn valve seals or bent valves, will cause compression problems.

4. Ignition System

The ignition system provides the spark to ignite the air-fuel mixture. Key components include:

- Battery: Provides the initial power for the ignition system.

- Ignition Coil: Steps up the battery voltage to create a high-voltage spark. Many modern vehicles use coil-on-plug (COP) systems, where each cylinder has its own coil.

- Spark Plugs: Create the spark inside the combustion chamber. Worn or fouled spark plugs are a very common cause of misfires.

- Ignition Control Module (ICM) or Engine Control Unit (ECU): Controls the timing and duration of the spark.

- Distributor (in older vehicles): Distributes the spark to the correct cylinder.

How It Works: The Four-Stroke Cycle

Most modern engines operate on a four-stroke cycle:

- Intake: The intake valve opens, and the piston moves down, drawing air (and fuel in port-injected engines) into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture.

- Combustion (Power): The spark plug ignites the compressed air-fuel mixture, forcing the piston down and generating power.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder.

A misfire occurs when one or more of these steps fails to occur correctly, preventing proper combustion.

Real-World Use: Basic Troubleshooting Tips

If your engine is misfiring, here's a basic troubleshooting approach:

- Check the Check Engine Light (CEL): Use an OBD-II scanner to read the diagnostic trouble codes (DTCs). A code like P0300 (random misfire) or P0301 (misfire cylinder 1) can point you in the right direction.

- Inspect Spark Plugs: Remove and inspect the spark plugs. Look for wear, cracks, fouling (carbon buildup), or damage. Replace them if necessary. Pay attention to which cylinder the bad plug came from – that’s your problem area.

- Check Ignition Coils: If you have a COP system, you can try swapping coils between cylinders to see if the misfire moves with the coil. If it does, the coil is likely the culprit.

- Inspect Fuel Injectors: Listen to the fuel injectors with a stethoscope (or a long screwdriver held to your ear) to see if they are clicking. If one isn't clicking, it may be clogged or faulty. Fuel injector cleaner can sometimes help.

- Check for Vacuum Leaks: Vacuum leaks can disrupt the air-fuel mixture and cause misfires. Inspect vacuum hoses for cracks or disconnections. A simple spray of carb cleaner around vacuum lines can help find a leak – the engine will rev up if it sucks in the cleaner.

- Perform a Compression Test: This will reveal any compression problems caused by worn piston rings, leaky valves, or a blown head gasket.

Safety First! Risk Components

Working on your engine involves certain safety risks:

- High Voltage: The ignition system generates very high voltage, which can be dangerous. Always disconnect the negative battery cable before working on the ignition system. Never touch spark plug wires or coils while the engine is running.

- Fuel: Fuel is flammable and can be harmful if inhaled or ingested. Work in a well-ventilated area and avoid spilling fuel.

- Hot Surfaces: The engine and exhaust system can get very hot. Allow the engine to cool down before working on it.

- Moving Parts: Be extremely careful when working around moving engine parts. Keep your hands and tools clear of belts, pulleys, and fans.

- Exhaust Fumes: Exhaust fumes contain carbon monoxide, which is a deadly gas. Never run an engine in an enclosed space.

Important Notes: * Always consult your vehicle's repair manual for specific procedures and torque specifications. * If you're not comfortable performing any of these repairs yourself, take your vehicle to a qualified mechanic.

Conclusion

Misfires can be frustrating, but by understanding the underlying causes and following a systematic troubleshooting approach, you can often diagnose and repair them yourself. Remember to prioritize safety and consult your vehicle's repair manual for specific instructions. Good luck!