What Causes Dry Rot In Tires

Let's dive into a critical, often overlooked aspect of tire health: dry rot, also known as sidewall cracking or weather cracking. As experienced DIYers, we understand the importance of maintaining all aspects of our vehicles, and tires are no exception. Dry rot, if left unchecked, can lead to dangerous situations, including tire failure at speed. This article will give you a solid understanding of the causes of dry rot, how to spot it, and what you can do about it.

Understanding Dry Rot: A Technical Deep Dive

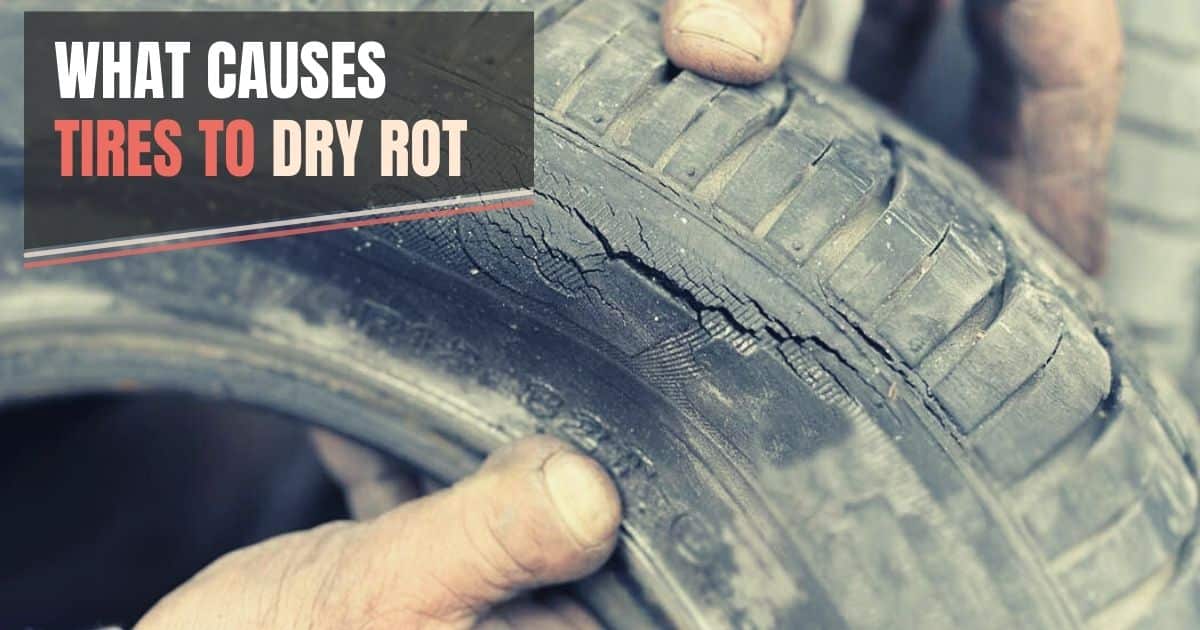

Dry rot, technically known as ozone cracking or weather cracking, is the deterioration of tire rubber, particularly in the sidewall, due to environmental factors. It manifests as small cracks or fissures appearing on the surface of the tire. These cracks initially are cosmetic, but they can deepen over time and compromise the tire's structural integrity.

Purpose of Understanding Dry Rot

Knowing the causes and signs of dry rot is crucial for several reasons:

- Safety: Preventing tire failure, which can lead to accidents.

- Cost Savings: Identifying and addressing dry rot early can extend the lifespan of your tires, delaying the need for replacements.

- Informed Decisions: Knowing the condition of your tires empowers you to make informed decisions about tire rotation, maintenance, and replacement.

Key Specs and Main Parts Involved

The main components involved in dry rot are:

- Sidewall Rubber Compound: The rubber compound used in the sidewall is specifically formulated for flexibility and weather resistance. However, it's still susceptible to degradation.

- Antiozonants and Antioxidants: These chemical additives are included in the rubber compound to protect against ozone and oxidation. Their effectiveness diminishes over time.

- Tire Carcass: The underlying structure of the tire, made of layers of fabric (typically polyester or nylon) and steel belts. Dry rot weakens the sidewall rubber, exposing the carcass to potential damage.

- Bead: The edge of the tire that sits securely on the wheel rim. Severe dry rot near the bead can compromise the tire's seal.

How It Works: The Chemistry of Dry Rot

Dry rot is primarily caused by a combination of the following factors:

- Ozone Exposure: Ozone (O3), a highly reactive form of oxygen, is naturally present in the atmosphere and is also produced by electrical equipment. Ozone attacks the double bonds in the unsaturated polymers of the rubber compound. This attack leads to chain scission (breaking of the polymer chains), making the rubber brittle and prone to cracking. The effect is accelerated by stress and flexing of the tire.

- Ultraviolet (UV) Radiation: UV light from the sun also contributes to rubber degradation. UV radiation breaks down the chemical bonds in the rubber compound, making it less elastic.

- Oxidation: Oxygen in the air reacts with the rubber compound, leading to oxidation. This process causes the rubber to harden and crack.

- Temperature Fluctuations: Extreme temperature swings cause the rubber to expand and contract, placing stress on the sidewall. This stress exacerbates the effects of ozone, UV radiation, and oxidation.

- Lack of Use: Ironically, tires that sit for extended periods are more susceptible to dry rot than tires that are regularly used. When a tire is driven, the antiozonants and antioxidants migrate to the surface, providing a protective layer. When a tire sits idle, these chemicals do not migrate, leaving the rubber vulnerable to attack.

The chemical process of ozone cracking can be summarized as follows:

Rubber + Ozone → Rubber Oxide (Cracked Rubber)

The antioxidants included in the tire formulation are designed to act as radical scavengers, intercepting free radicals formed during the oxidation process and preventing further degradation.

Real-World Use: Troubleshooting Dry Rot

Here's how to troubleshoot dry rot in your tires:

- Visual Inspection: Regularly inspect your tires for signs of cracking, especially on the sidewalls. Look closely for small, hairline cracks. Pay particular attention to the area between the tread and the bead.

- Flexing the Sidewall: Gently flex the sidewall of the tire. If you see cracks opening and closing, it's a sign of dry rot.

- Age Check: Check the DOT code on your tires. The last four digits indicate the week and year of manufacture. Even if your tires look good, tires older than six years should be inspected by a professional, as the rubber compound may have degraded significantly, even with limited use.

- Tire Pressure: Maintaining proper tire pressure helps prevent excessive stress on the sidewalls. Under-inflation can exacerbate dry rot.

If you find dry rot, consider the following:

- Mild Cracking: If the cracking is very minor and superficial, you may be able to continue using the tires, but monitor them closely. Consider using a tire protectant that contains antiozonants and UV inhibitors. However, these products are often more cosmetic than protective against serious dry rot.

- Moderate to Severe Cracking: If the cracks are deep or widespread, it's time to replace the tires. Continuing to use tires with moderate to severe dry rot is dangerous and can lead to tire failure.

Safety: Risky Components and Considerations

The sidewall of the tire is the most vulnerable area when dry rot is present. A compromised sidewall can lead to a sudden loss of air pressure, causing a blowout. This is especially dangerous at high speeds.

Never attempt to repair a tire with dry rot on the sidewall. Patching or plugging the tire will not address the underlying problem, and the tire will still be at risk of failure. Replacement is the only safe solution.

Also, be aware that tires stored improperly (e.g., outdoors, exposed to sunlight and ozone) are more likely to develop dry rot. Store tires in a cool, dry, and dark place.

Diagrammatic Representation (Hypothetical)

While I can't embed an interactive diagram here, imagine a diagram with the following features:

Symbols and Lines

- Solid Lines: Represent the layers of the tire (tread, sidewall, carcass, bead).

- Dotted Lines: Indicate cracks in the sidewall. The density and depth of the dotted lines would correspond to the severity of the dry rot.

- Arrows: Showing the direction of ozone and UV radiation impacting the tire.

- Color Coding: Could be used to show areas of rubber degradation (e.g., lighter shades of gray for mildly affected areas, darker shades for severely affected areas).

- Icons: A sun icon to represent UV exposure, a lightning bolt icon to represent ozone generation from electrical equipment.

Diagram Parts and Functions

- Cross-Section of Tire: Shows the different layers of the tire and how dry rot affects the sidewall.

- Chemical Reaction Diagram: Illustrates the breakdown of the rubber polymer chains due to ozone exposure.

- Close-Up of Cracks: A magnified view of the cracks, showing their depth and orientation.

Purpose of the diagram: To visually represent the process of dry rot and highlight the vulnerable areas of the tire. It aids in understanding the damage at a deeper level.

We have a detailed diagram outlining this whole process and tire anatomy! It's quite comprehensive, showing the key components, the chemical reactions, and the visual signs of dry rot. You can download the diagram [link to a hypothetical diagram file] here. It's a valuable resource for anyone looking to understand dry rot in detail.

Understanding dry rot and taking preventative measures can significantly extend the life of your tires and improve the safety of your vehicle. Regular inspections and proper tire maintenance are essential for all experienced DIYers. Safe driving!