What Causes Dry Rot On Tires

Alright, let's talk about dry rot on tires. It's a common problem, especially in certain climates and with vehicles that sit for extended periods. As an experienced DIYer, you've probably encountered it or at least heard the term, but let's dive deep into the causes and what you can do about it. We'll use a technical diagram later to visualize the breakdown.

What is Dry Rot?

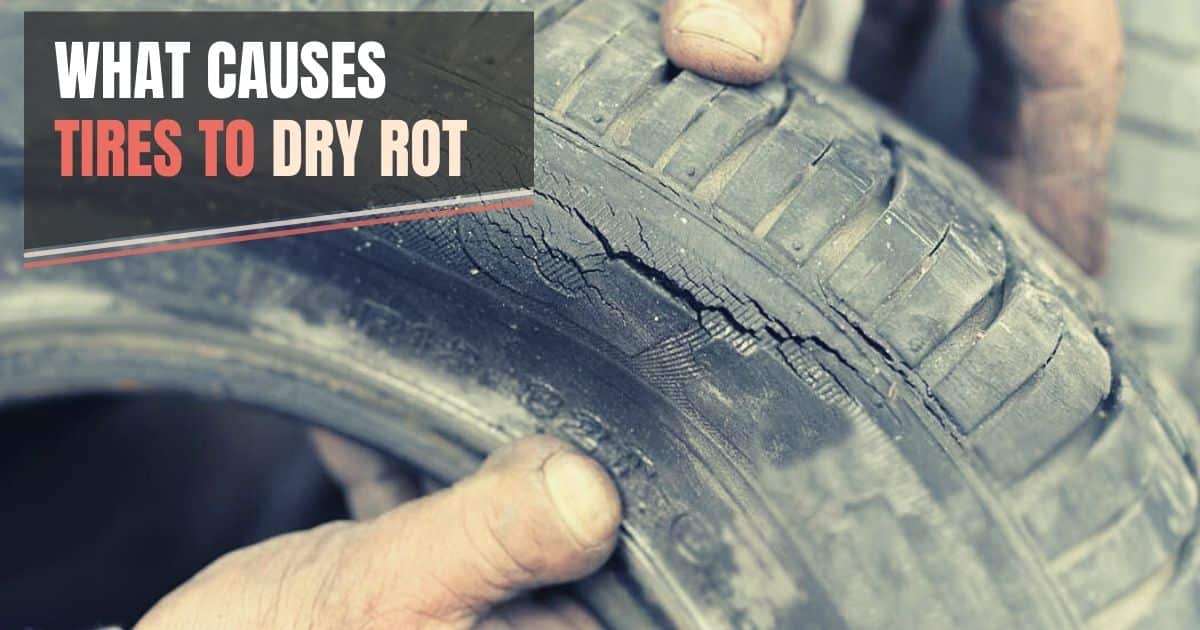

First things first, dry rot, also known as sidewall cracking or ozone cracking, isn't actually "rot" in the biological sense like wood rot. It's the degradation of the rubber compound in your tires, leading to surface cracks and, in severe cases, complete tire failure. The cracks appear as small, hairline fissures on the sidewalls, sometimes extending down into the tread area. Early detection is key to preventing a catastrophic blowout. In extreme cases, the tire can separate, leading to a loss of vehicle control.

The Purpose of Understanding Dry Rot

Why is understanding dry rot so important? Simple. Safety and cost. Identifying and addressing dry rot early allows you to replace tires before they fail, preventing accidents and potentially saving you from more extensive vehicle damage. It also allows you to make informed decisions about tire care and storage, prolonging the lifespan of your tires and saving you money in the long run.

Key Specs and Main Parts of a Tire Related to Dry Rot

To understand the causes of dry rot, we need to look at the basic structure of a tire, focusing on the components most susceptible to degradation:

- Sidewall: The most visible area affected by dry rot. Composed of various rubber compounds designed for flexibility and protection of the tire's carcass. This is the primary area where cracking will appear.

- Tread: While the tread itself can experience cracking from wear and tear, dry rot can extend into the tread area from the sidewall. The tread compound is designed for grip and durability, but it's still susceptible to UV damage and ozone.

- Carcass (or Casing): The structural foundation of the tire, made of layers of fabric (typically polyester or nylon) embedded in rubber. Although not directly affected visibly by dry rot, severe cracking can expose the carcass to moisture and further degradation, causing the tire to weaken.

- Rubber Compounds: Tires are not made of a single type of rubber. They are crafted from a sophisticated mix of natural and synthetic rubbers, reinforcing agents (like carbon black), antioxidants, antiozonants, and other chemicals that influence the tire's properties. The degradation of these compounds is the root cause of dry rot.

The Chemistry Behind Dry Rot: How it Works

Dry rot is primarily caused by a combination of factors, all working together to break down the rubber compounds in your tires. The main culprits are:

- Ozone (O3): Ozone is a powerful oxidizing agent, meaning it readily reacts with other substances, causing them to degrade. It's found naturally in the atmosphere, but its concentration is higher in urban areas due to pollution from car exhaust and industrial processes. Ozone attacks the double bonds in the rubber polymers, causing them to break and become brittle. This leads to the formation of micro-cracks on the tire surface.

- Ultraviolet (UV) Radiation: Sunlight is a major source of UV radiation, which also degrades rubber compounds. UV light breaks down the chemical bonds in the rubber, causing it to harden and crack.

- Heat: High temperatures accelerate the rate of chemical reactions, including the degradation caused by ozone and UV radiation. Tires that are constantly exposed to heat, especially in hot climates, are more prone to dry rot.

- Lack of Use: Ironically, tires that sit unused for long periods are more susceptible to dry rot than tires that are regularly used. When a tire is in use, the flexing of the rubber helps to release protective oils and waxes that migrate to the surface, forming a barrier against ozone and UV damage. When a tire sits idle, these oils and waxes don't migrate to the surface, leaving the rubber unprotected.

- Chemical Exposure: Contact with certain chemicals, such as solvents, oils, and cleaning products, can also damage tire rubber and accelerate dry rot.

- Age: Even with proper care, tire rubber degrades over time. The older a tire is, the more likely it is to develop dry rot, regardless of how much it's been used.

Think of it this way: the rubber compounds in your tires are like a chain. Ozone, UV radiation, heat, and lack of use act like rust, slowly weakening the individual links in the chain. Over time, these links break, leading to cracks and ultimately, tire failure.

Real-World Use: Basic Troubleshooting and Prevention Tips

Now that you understand the causes of dry rot, let's talk about what you can do to prevent it and how to troubleshoot potential problems:

- Regular Inspections: Regularly inspect your tires for signs of cracking, especially on the sidewalls. Pay close attention to tires that are several years old or that have been exposed to harsh conditions.

- Proper Tire Pressure: Maintaining proper tire pressure helps to distribute stress evenly across the tire, reducing the risk of cracking. Underinflated tires flex more, which can accelerate dry rot.

- Tire Rotation: Rotating your tires regularly helps to distribute wear evenly and prevents any one tire from being exposed to the same conditions for too long.

- Protect from Sunlight: When possible, park your vehicle in a garage or shaded area to protect the tires from direct sunlight. If you can't park in a covered area, consider using tire covers.

- Store Tires Properly: If you're storing tires, clean them thoroughly, wrap them in airtight bags, and store them in a cool, dry, and dark place.

- Use Tire Protectants (with caution): Some tire protectants claim to protect against UV damage and ozone. However, some products can actually damage the rubber. Be cautious and choose products that are specifically designed for tires and that are recommended by the tire manufacturer. Avoid petroleum-based products.

- Check the Manufacturing Date: Look for the DOT (Department of Transportation) code on the tire sidewall. The last four digits indicate the week and year the tire was manufactured. For example, "1223" means the tire was manufactured in the 12th week of 2023. Even if a tire looks new, it might be several years old and more susceptible to dry rot.

Troubleshooting Tip: If you notice minor surface cracking, you might be able to continue using the tires for a while, but monitor them closely. If the cracks become deeper or wider, or if you notice bulging or other signs of tire damage, replace the tires immediately.

Safety: Risky Components and Critical Considerations

Tires are a critical safety component of your vehicle. Driving on tires with severe dry rot is extremely dangerous and can lead to:

- Blowouts: A blowout can cause you to lose control of your vehicle, potentially leading to an accident.

- Tire Separation: The tread can separate from the tire carcass, causing the tire to destabilize and potentially damage your vehicle.

- Reduced Traction: Cracked tires have reduced traction, especially in wet or snowy conditions, increasing the risk of skidding and accidents.

Important Safety Note: Never attempt to repair dry rot. There are no effective methods for repairing dry rot, and any attempts to do so are likely to fail and could make the tires even more dangerous. The only safe solution is to replace the affected tires.

Technical Diagram: Visualizing the Breakdown

To further illustrate the process of dry rot, consider the technical diagram below (which, unfortunately, I can't display directly in this text-based response). In this diagram, you'd typically see:

- Key Specs and Main Parts: The diagram would highlight the sidewall, tread, carcass, and rubber compounds.

- Symbols: Lines would represent cracks, colors might indicate the severity of degradation (e.g., yellow for minor cracking, red for severe cracking), and icons could represent ozone molecules, UV radiation, and heat sources.

- How It Works: Arrows would show the direction of ozone and UV radiation attacking the rubber compounds. Close-up views would illustrate the breaking of polymer chains at a microscopic level.

This diagram provides a visual representation of the chemical breakdown occurring within the tire's rubber structure, making it easier to understand the causes and effects of dry rot.

We have a detailed technical diagram of tire dry rot that visually explains the process. You can download this file to get a better understanding of the causes and how to prevent it.

By understanding the causes of dry rot and taking preventative measures, you can help prolong the life of your tires and ensure your safety on the road. Remember, regular inspections and prompt replacement of damaged tires are crucial for maintaining vehicle safety.