What Causes Ticking In An Engine

Engine ticking. That seemingly innocuous sound can be the bane of any gearhead's existence. It's a noise that whispers, or sometimes screams, "Something's not quite right in your engine." This article dives deep into the most common causes of engine ticking, equipping you, the experienced DIYer, with the knowledge to diagnose and potentially address the problem. We'll break down the complexities with clear explanations and practical troubleshooting tips.

Why Understanding Engine Ticking Matters

Identifying the source of a ticking sound is crucial for several reasons. First and foremost, it prevents potential catastrophic engine failure. A small tick can quickly escalate into a major breakdown if ignored. Secondly, early diagnosis can save you significant money on repairs. Addressing a minor valve issue is far cheaper than replacing an entire engine. Finally, understanding the underlying causes enhances your overall understanding of engine mechanics, empowering you to perform preventative maintenance and make informed decisions about your vehicle.

Key Specs and Main Parts Involved in Engine Ticking

To understand ticking, you need to be familiar with certain engine components. Here are the key players:

- Valves: These control the intake of air and fuel and the exhaust of combustion gases. They open and close at precise intervals, allowing the engine to breathe. Valve lash, the clearance between the valve stem and the rocker arm or cam follower, is critical.

- Rocker Arms/Cam Followers (Lifters): These transmit the motion of the camshaft to the valves. There are two main types: hydraulic and mechanical. Hydraulic lifters use oil pressure to maintain proper valve lash, while mechanical lifters require manual adjustment.

- Camshaft: A rotating shaft with lobes (cams) that push on the lifters/followers to open the valves. Wear on the cams can lead to incorrect valve timing and ticking.

- Connecting Rods: Connect the pistons to the crankshaft. Bearings at both ends allow for smooth rotation.

- Pistons: Move up and down within the cylinders, compressing the air-fuel mixture and being driven by the combustion.

- Crankshaft: Converts the reciprocating motion of the pistons into rotary motion, which powers the vehicle.

- Oil Pump: Circulates oil throughout the engine to lubricate moving parts and reduce friction. Low oil pressure can cause or exacerbate ticking sounds.

- Exhaust Manifold: Collects exhaust gases from the cylinders. Leaks in the exhaust manifold can sometimes mimic a ticking sound.

How an Engine Works (Simplified)

An engine operates on a four-stroke cycle: intake, compression, combustion, and exhaust. During the intake stroke, the intake valve opens, allowing air and fuel to enter the cylinder. The piston then moves up, compressing the mixture. At the peak of compression, the spark plug ignites the mixture, forcing the piston down during the combustion stroke. Finally, the exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder. This cycle repeats continuously. The valves, controlled by the camshaft, play a critical role in this process.

Common Causes of Engine Ticking

Here's a breakdown of the most frequent culprits behind that annoying ticking sound:

- Valve Lash Problems: This is the most common cause. Insufficient valve lash creates a ticking sound as the rocker arm or cam follower "taps" against the valve stem. This is more common in engines with mechanical lifters, which require periodic adjustment. Hydraulic lifters are supposed to self-adjust, but they can become clogged or fail, leading to excessive valve lash.

- Collapsed Hydraulic Lifter: If a hydraulic lifter fails to maintain oil pressure, it can collapse, creating excessive valve lash and a noticeable tick.

- Exhaust Leak: A small leak in the exhaust manifold or a gasket can produce a ticking sound, especially when the engine is cold. As the metal heats up, the leak may seal slightly, reducing or eliminating the noise.

- Low Oil Pressure: Insufficient oil pressure can prevent hydraulic lifters from functioning correctly and can also cause excessive wear on bearings, leading to a ticking or knocking sound.

- Worn Rod Bearings (Rod Knock): This is a more serious issue. Worn bearings in the connecting rods allow excessive play, resulting in a knocking or ticking sound, particularly under load. This sound is often deeper and more pronounced than a valve tick.

- Piston Slap: Occurs when the piston rocks back and forth in the cylinder due to excessive clearance. This can be caused by wear or improper piston installation.

- Fuel Injector Tick: Fuel injectors can sometimes produce a faint ticking sound as they open and close. This is usually normal, but excessive ticking from an injector could indicate a problem.

Real-World Use: Troubleshooting Engine Ticking

Here's a basic troubleshooting approach:

- Listen Carefully: Try to pinpoint the location of the ticking sound. Is it coming from the top of the engine (valve train) or the bottom (crankshaft/connecting rods)?

- Check Oil Level and Pressure: Ensure the engine has sufficient oil and that the oil pressure is within the normal range. A low oil level or pressure reading is a red flag.

- Inspect for Exhaust Leaks: Look for black soot around the exhaust manifold and gaskets. You can also use a stethoscope or a piece of hose to listen for leaks near the exhaust system.

- Valve Lash Adjustment: If you suspect valve lash problems, check the valve lash according to your vehicle's service manual and adjust as needed (if applicable to your engine type).

- Use a Mechanic's Stethoscope: A stethoscope can help you isolate the source of the noise. Place the probe on different parts of the engine while it's running to listen for the ticking sound.

- Consider an Oil Analysis: An oil analysis can reveal the presence of metal particles, which could indicate bearing wear or other internal engine damage.

Safety Considerations

Working on a running engine involves several safety risks:

- High Temperatures: The engine and exhaust system can get extremely hot. Wear gloves and use caution to avoid burns.

- Moving Parts: Keep your hands and clothing away from moving parts like belts, pulleys, and fans.

- Electrical Hazards: Be careful when working around the ignition system. High voltage can be dangerous.

- Flammable Materials: Keep flammable materials away from the engine. Gasoline and other fluids can ignite easily.

- Exhaust Fumes: Work in a well-ventilated area to avoid inhaling exhaust fumes. Carbon monoxide is a deadly gas.

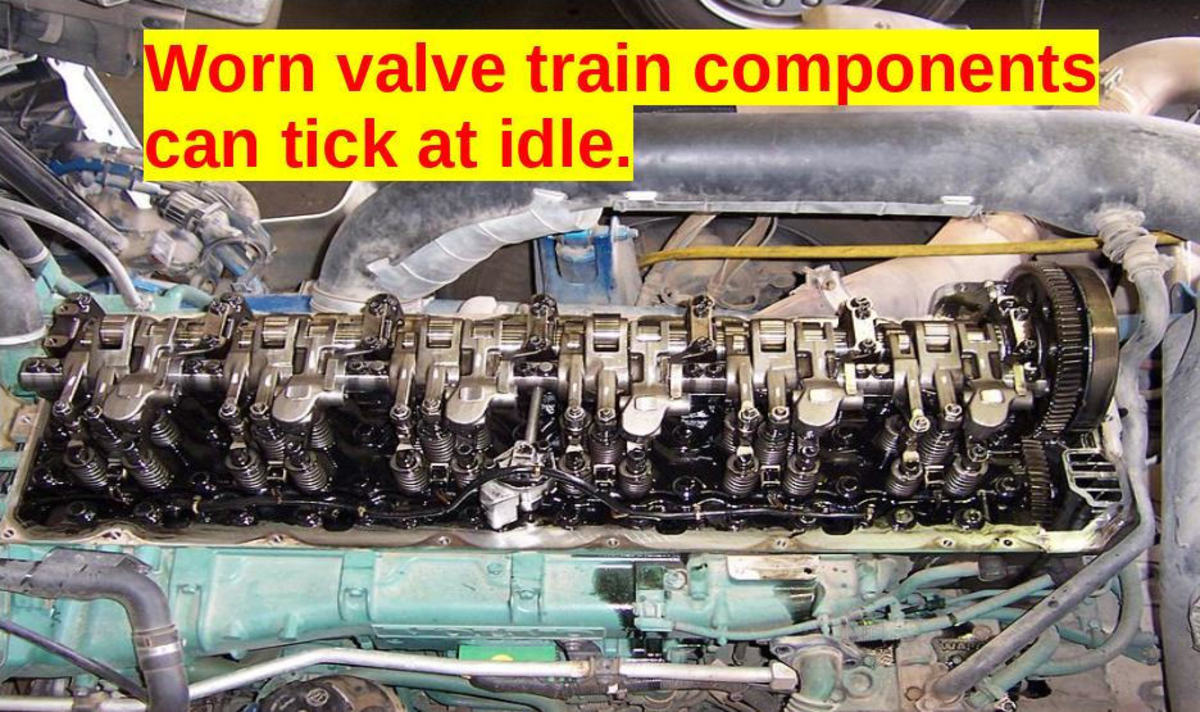

Diagram of Engine Components

For a comprehensive understanding of engine components and their relationship, refer to the detailed engine diagram. This diagram illustrates the location of various engine parts, including valves, lifters, camshaft, connecting rods, pistons, and crankshaft. Analyzing this diagram alongside the troubleshooting steps can greatly help you in identifying the potential source of the ticking sound.

Purpose – The diagram is invaluable for identifying components mentioned in this article and understanding their spatial relationships within the engine. This assists in pinpointing the potential source of a tick and planning repairs. It's also a great learning tool for understanding engine mechanics.

Key Specs and Main Parts – The diagram highlights: Cylinder head, Valve train components (valves, springs, retainers, rockers, lifters/followers), Camshaft, Pistons, Connecting Rods, Crankshaft, Oil Pan, and the location of various sensors and hoses.

Symbols – The diagram typically uses line weights to differentiate between components. Colors are often used to highlight different systems (e.g., lubrication, cooling). Icons might represent sensors or electrical components.

Download the Engine Diagram

A detailed engine diagram is an invaluable resource for any DIY mechanic. We have a high-resolution diagram available for you to download. This diagram will help you visualize the engine components discussed in this article and aid in your troubleshooting efforts.

Note: While this article provides general guidance, it's essential to consult your vehicle's service manual for specific instructions and torque specifications. If you're unsure about any repair procedure, it's best to seek the advice of a qualified mechanic.