What Do Cylinders Mean In A Car

Okay, let's dive deep into engine cylinders. If you're wrenching on your own car, modifying it for performance, or even just trying to understand what the mechanic is talking about, grasping the fundamentals of cylinders is crucial. We're not just talking about knowing how many your engine has; we're talking about understanding how they work, what components they contain, and how that knowledge translates into real-world diagnostics and repair. Think of this article as your comprehensive guide to everything cylinder-related.

Purpose: Why Understanding Cylinders Matters

Why spend time learning about cylinders? Several reasons spring to mind, especially for the DIY enthusiast:

- Diagnostics & Troubleshooting: Misfires, low compression, and unusual noises are often cylinder-related. Knowing the cylinder layout and function helps pinpoint the problem quickly.

- Performance Tuning: Increasing displacement, changing compression ratios, and optimizing combustion all revolve around cylinder modifications.

- Repair & Maintenance: Replacing piston rings, honing cylinder walls, or dealing with head gasket issues requires a solid understanding of cylinder anatomy.

- General Knowledge: Simply put, it's empowering! Understanding your engine empowers you to make informed decisions about its care and potential modifications.

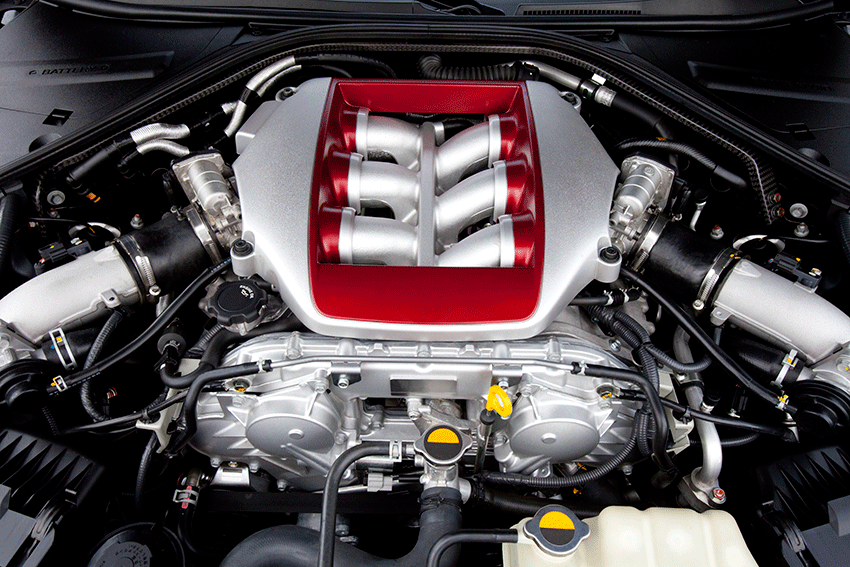

Key Specs and Main Parts

Let's break down the key components and specifications related to cylinders:

Main Parts of a Cylinder

- Cylinder Block: The foundation of the engine, housing the cylinders. Typically made of cast iron or aluminum.

- Cylinder Bore: The internal diameter of the cylinder. This is where the piston moves.

- Piston: A cylindrical component that moves up and down within the cylinder, driven by expanding gases during combustion.

- Piston Rings: Circular rings fitted into grooves on the piston, sealing the combustion chamber and preventing oil from entering. Important rings include the compression ring(s) and the oil control ring.

- Connecting Rod (Con-Rod): Connects the piston to the crankshaft, translating the piston's linear motion into rotational motion.

- Crankshaft: A rotating shaft that converts the reciprocating motion of the pistons into rotary motion, which drives the wheels.

- Cylinder Head: Sits atop the cylinder block, containing the valves, spark plugs (in gasoline engines), and combustion chamber.

- Valves (Intake & Exhaust): Control the flow of air/fuel mixture into the cylinder (intake valve) and exhaust gases out of the cylinder (exhaust valve).

- Spark Plug (Gasoline Engines): Ignites the air/fuel mixture within the combustion chamber.

- Injector (Fuel Injection): Sprays fuel into the intake manifold or directly into the cylinder.

Key Specifications

- Bore: The diameter of the cylinder bore. Usually measured in millimeters (mm) or inches (in).

- Stroke: The distance the piston travels from Top Dead Center (TDC) to Bottom Dead Center (BDC). Also measured in mm or inches.

- Displacement: The volume swept by the piston as it moves from TDC to BDC, calculated as π * (Bore/2)^2 * Stroke * Number of Cylinders. Usually measured in liters (L) or cubic centimeters (cc). Larger displacement generally means more power.

- Compression Ratio: The ratio of the cylinder volume when the piston is at BDC to the cylinder volume when the piston is at TDC. A higher compression ratio generally leads to more power and efficiency, but also requires higher octane fuel.

- Cylinder Head Volume: The volume of the combustion chamber when the piston is at TDC. Crucial for calculating compression ratio.

How It Works: The Four-Stroke Cycle

Most car engines operate on a four-stroke cycle, meaning it takes four piston strokes (two revolutions of the crankshaft) to complete one combustion cycle. Let's break it down:

- Intake Stroke: The piston moves down, creating a vacuum in the cylinder. The intake valve opens, allowing the air/fuel mixture (or just air in direct injection engines) to be drawn into the cylinder.

- Compression Stroke: The piston moves up, compressing the air/fuel mixture. Both intake and exhaust valves are closed. This compression increases the temperature of the mixture, making it easier to ignite.

- Combustion (Power) Stroke: The spark plug ignites the compressed air/fuel mixture, creating a rapid expansion of gases. This force pushes the piston down, turning the crankshaft and producing power.

- Exhaust Stroke: The piston moves up, pushing the burnt exhaust gases out of the cylinder. The exhaust valve is open.

Real-World Use: Basic Troubleshooting Tips

Understanding cylinder operation is invaluable for troubleshooting. Here are a few examples:

- Misfire: A misfire occurs when one or more cylinders fail to fire correctly. This can be caused by a faulty spark plug, a bad ignition coil, a clogged fuel injector, or low compression. Identifying the specific cylinder that's misfiring is the first step in diagnosing the problem. A compression test can reveal leaky valves or worn piston rings.

- Low Compression: Low compression in a cylinder indicates a leak in the combustion chamber. This could be due to worn piston rings, damaged valves, or a blown head gasket. A leak-down test can help pinpoint the source of the leak.

- Oil Consumption: Excessive oil consumption can be caused by worn piston rings or damaged valve stem seals, allowing oil to enter the combustion chamber and be burned.

- Coolant in Oil: This is a serious problem, often indicating a blown head gasket or a cracked cylinder head/block. Coolant leaking into the oil can cause significant engine damage. Look for a milky substance on the dipstick.

Safety: Highlight Risky Components

Working on engine cylinders involves several potential hazards:

- High Temperatures: Engine components can be extremely hot, even long after the engine has been shut off. Always allow the engine to cool completely before working on it.

- High Pressures: The combustion process generates extremely high pressures inside the cylinders. Never attempt to disassemble pressurized components without proper tools and precautions.

- Flammable Fluids: Gasoline and other engine fluids are highly flammable. Always work in a well-ventilated area and take precautions to prevent spills and ignition.

- Moving Parts: Be extremely careful when working around moving engine parts, such as the crankshaft and camshaft. Always disconnect the battery before working on the engine to prevent accidental starting.

- Sharp Edges: Cylinder blocks and heads can have sharp edges. Wear gloves to protect your hands.

- Head Gasket: If you are working on the head gasket, be aware that the cylinder head is heavy and requires careful handling to avoid injury or damage. Use proper lifting equipment when needed.

Important Safety Note: If you're unsure about any aspect of engine repair, consult a qualified mechanic. Working on engines can be dangerous if you don't know what you're doing.