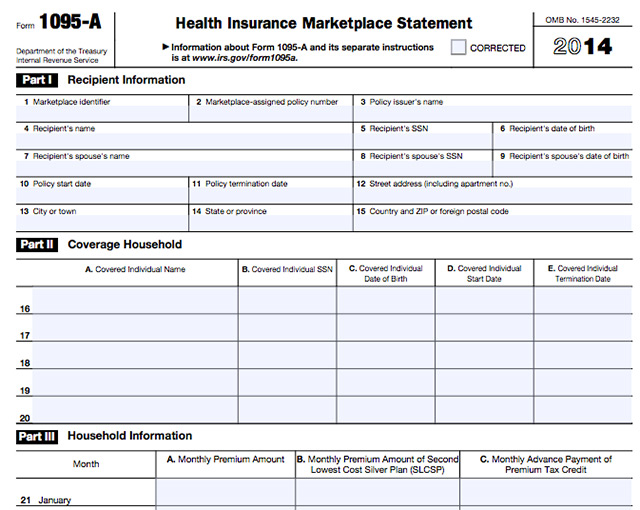

What Does 1095 A Look Like

Alright, let's dive into understanding a 1095 schematic. Think of it as the blueprint for your car's brain – the electronic control unit (ECU) and all the components it interacts with. Knowing how to read and interpret a 1095 diagram is crucial for serious DIYers, modders, and anyone tackling complex automotive repairs. This isn't just about slapping on a new part; it's about understanding the system, diagnosing problems accurately, and making informed decisions. We'll break it down into manageable chunks, so you can confidently use these schematics in your garage.

Purpose: Why This Diagram Matters

The primary purpose of a 1095 schematic (or wiring diagram) is to illustrate the electrical connections within a vehicle's system. It's a visual representation of how different components are wired together, including the ECU, sensors, actuators, relays, and fuses. Understanding this diagram allows you to:

- Troubleshoot Electrical Issues: Pinpoint shorts, opens, and other wiring problems.

- Perform Modifications: Safely add or modify existing circuits.

- Understand System Operation: Gain insight into how different components interact.

- Verify Wiring Integrity: Ensure proper connections during repairs or installations.

- Prevent Damage: Avoid accidentally damaging components by miswiring.

Without a 1095, you're essentially working blind, relying on guesswork and potentially causing more harm than good. These diagrams are essential for accurate and efficient diagnosis and repair.

Key Specs and Main Parts of a 1095 Schematic

A typical 1095 schematic will include several key pieces of information:

- Component Symbols: Each component (sensor, relay, motor, etc.) is represented by a specific symbol. We'll get into symbol identification later.

- Wire Numbers/Colors: Each wire is identified by a number and/or color code, which helps you trace it throughout the system.

- Connectors: These show where wires are joined together using connectors. Connector diagrams are often included separately to show pin layouts.

- Ground Points: These indicate where circuits are grounded to the vehicle's chassis.

- Voltage Sources: Indicate the power supply voltage (e.g., 12V, 5V).

- Fuses and Relays: Schematics clearly show the location and amperage of fuses and the types of relays used.

- ECU (Electronic Control Unit): This is the brain of the system. The schematic will show all the input and output signals connected to the ECU.

Understanding these elements is the foundation for reading any 1095 diagram. Let's break down the symbols further.

Component Symbols: Deciphering the Code

Component symbols are standardized, but they can vary slightly depending on the manufacturer. Here are some of the most common symbols you'll encounter:

- Resistor: A zigzag line.

- Capacitor: Two parallel lines (may be curved for electrolytic capacitors).

- Inductor/Coil: A series of loops.

- Diode: A triangle pointing to a vertical line.

- Transistor: Various symbols depending on the type (NPN, PNP, FET, etc.).

- Ground: Three horizontal lines, decreasing in length.

- Fuse: A short line connecting two points, or a stylized "S" shape.

- Relay: A coil with a switch controlled by the coil. The switch can be normally open (NO) or normally closed (NC).

- Sensor: Can vary greatly, often a box with an arrow pointing into it or a specialized symbol representing the sensor type (e.g., a crankshaft position sensor).

- Actuator: Similar to sensors, these can vary but often involve a box with an arrow pointing out. Examples include fuel injectors and solenoids.

- Switch: Shows the contact arrangement of the switch (e.g., SPST, SPDT, DPST, DPDT).

Consult the specific 1095's legend or key for the exact symbols used, as variations exist.

Symbols: Lines, Colors, and Icons

Besides component symbols, understanding the meaning of lines, colors, and icons is vital:

- Lines: Solid lines represent wires. Dashed lines might indicate shielded cables or connections that are not always present. Line thickness can sometimes indicate wire gauge (thicker lines = thicker wires), but this isn't always consistent.

- Colors: Wire colors are crucial for tracing wires in the real world. The schematic will list the color code for each wire (e.g., BLU for blue, RED for red, GRN for green). Often, wires have a primary color and a stripe (e.g., BLU/WHT = blue with a white stripe).

- Icons: Some schematics use icons to represent specific components, especially connectors. These icons can be simplified representations of the physical connector.

Pay close attention to color codes and connector pin assignments, as these are the most common sources of confusion. A small discrepancy in wire color can lead you down the wrong path.

How It Works: Tracing a Circuit

The key to understanding a 1095 is to trace the circuit from the power source (e.g., battery) to the ground. Here's the process:

- Identify the Power Source: Locate the voltage source (usually 12V).

- Follow the Wire: Trace the wire from the power source through fuses, relays, switches, and components. Use the wire number and color code to stay on the right path.

- Observe Interconnections: Note where the wire connects to other components or splices.

- Trace to Ground: Follow the circuit until it reaches a ground point.

- Understand Component Function: As you trace the circuit, understand the function of each component and how it affects the flow of current.

For example, let's say you're troubleshooting a faulty headlight. You'd start by locating the headlight circuit in the 1095. You'd then trace the wire from the battery through the fuse, switch, relay (if applicable), and finally to the headlight bulb. By tracing the circuit, you can identify potential points of failure, such as a blown fuse, a faulty switch, or a broken wire.

Real-World Use: Basic Troubleshooting Tips

Here are some practical troubleshooting tips using a 1095 schematic:

- No Power: If a component isn't working, start by checking the fuse. Use the 1095 to locate the correct fuse and verify that it's intact.

- Voltage Drop: Use a multimeter to measure the voltage at various points in the circuit. A significant voltage drop indicates a high-resistance connection or a faulty component.

- Continuity Testing: Use a multimeter to check for continuity between two points in the circuit. This can help you identify broken wires or open circuits. Always disconnect the power source before performing continuity testing.

- Short to Ground: If a circuit is drawing excessive current, there may be a short to ground. Use the 1095 to identify potential points where the circuit could be shorting to the chassis.

- Component Testing: Use the 1095 to identify the correct terminals for testing a component. Consult the manufacturer's specifications for the expected voltage or resistance readings.

Always compare your findings to the 1095 schematic to ensure that the actual wiring matches the diagram. Discrepancies can indicate wiring errors or modifications.

Safety: Risky Components

Working with automotive electrical systems can be dangerous. Here are some key safety precautions:

- Disconnect the Battery: Always disconnect the negative battery terminal before working on any electrical system. This prevents accidental shorts and electrocution.

- Airbags: Be extremely careful when working near airbag modules. Disconnecting and reconnecting airbags requires specific procedures. Consult the service manual for your vehicle.

- High-Voltage Systems: Hybrid and electric vehicles have high-voltage systems that can be lethal. Only qualified technicians should work on these systems.

- Fuel System: Be cautious when working near the fuel system. Disconnect the fuel pump relay before disconnecting any fuel lines.

- Proper Tools: Use insulated tools to prevent accidental shorts.

Specifically, be extremely careful around the ECU, airbag modules, and any high-voltage components. Mishandling these components can lead to serious injury or damage.

By carefully studying the 1095 schematic and following proper safety procedures, you can confidently diagnose and repair electrical issues in your vehicle.

We have a sample 1095 file available for download. This will provide you with a hands-on example to practice reading and interpreting the diagram. You can download the file here.