What Does 6 Cylinder Engine Mean

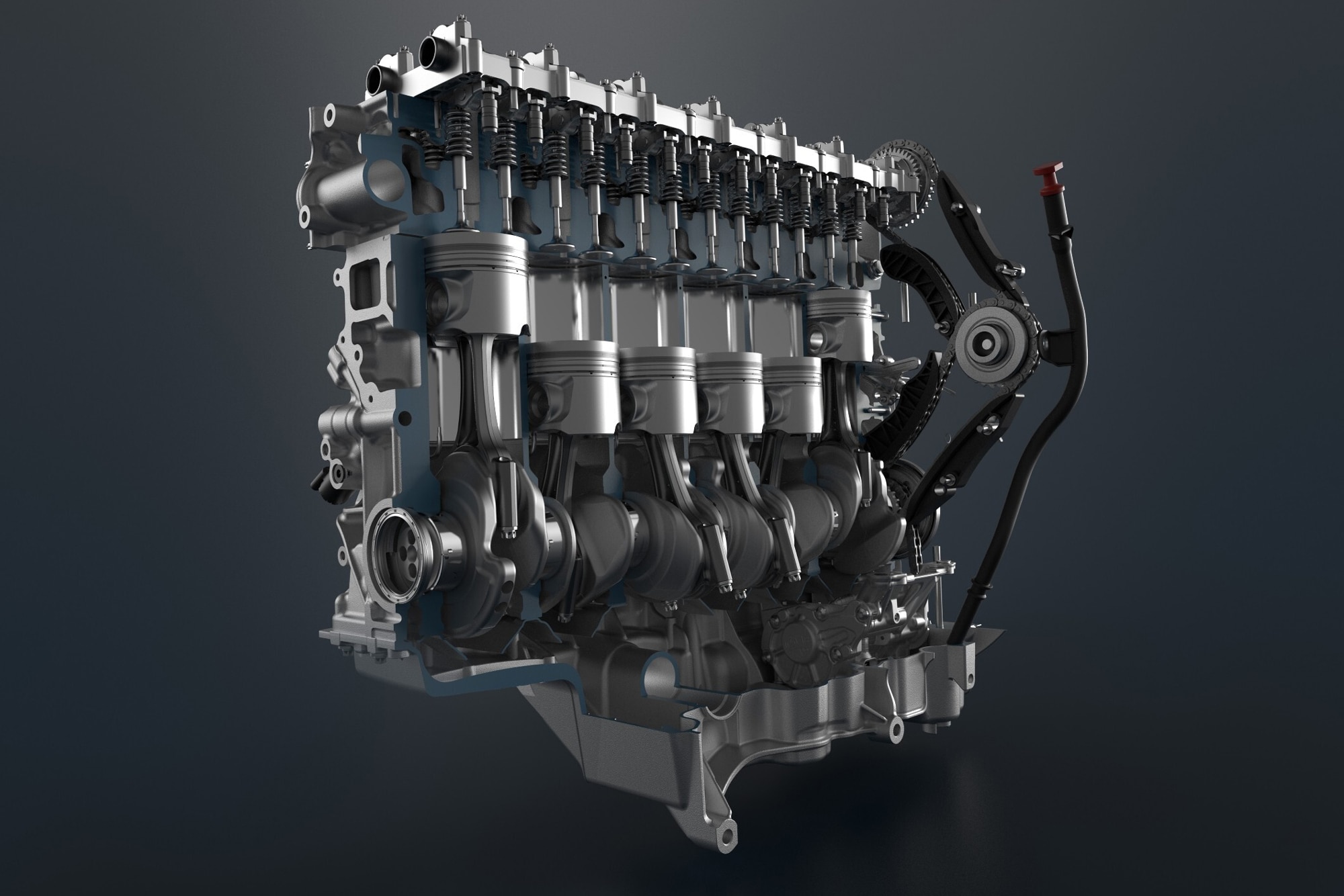

Alright, let's dive into the heart of the matter: what exactly *does* a 6-cylinder engine mean? If you're comfortable wrenching on your car, understanding the fundamentals of engine configuration, especially a 6-cylinder, is crucial. Whether you're planning performance mods, diagnosing a misfire, or just want to know your engine better, grasping the 6-cylinder layout will prove invaluable. We'll break down the components, function, and even some common problems you might encounter. And, as a bonus, we have a detailed diagram you can download at the end to help you visualize everything we cover.

Key Specs and Main Parts of a 6-Cylinder Engine

The most defining characteristic of a 6-cylinder engine is, unsurprisingly, the presence of six cylinders. But the specifics beyond that simple fact dictate its performance and characteristics. These engines can come in two primary configurations: inline-six (straight-six) and V6.

Inline-Six (I6)

In an inline-six, all six cylinders are arranged in a single straight line along the engine block. Historically, this configuration offered exceptional smoothness and balance due to its inherent mechanical properties. However, the length of the engine often presented packaging challenges in smaller engine bays, leading to its decline in popularity. You'll still find them in some BMWs, for instance, and they're prized for their characteristic sound and smooth power delivery.

V6 Engine

The V6 engine arranges the six cylinders in two banks of three cylinders, set at an angle to each other, forming a "V" shape. This configuration is much more compact than an inline-six, making it easier to fit into a wider range of vehicles. The angle between the cylinder banks can vary, with 60-degree and 90-degree V6s being the most common. Each angle has different benefits concerning engine balance and manufacturing complexity.

Key Components common to both configurations include:

- Cylinders: The chambers where combustion occurs. The bore (diameter of the cylinder) and stroke (distance the piston travels) define the cylinder's volume, which is a key factor in engine displacement (measured in liters or cubic inches).

- Pistons: Move up and down within the cylinders, driven by the expanding gases produced during combustion. They are connected to the connecting rods.

- Connecting Rods: Link the pistons to the crankshaft, converting the linear motion of the pistons into rotary motion.

- Crankshaft: The main rotating shaft that converts the reciprocating motion of the pistons into rotational power. The crankshaft's design (counterweights, etc.) is crucial for engine balance.

- Cylinder Head(s): Sits atop the cylinder block and houses the valves, spark plugs (in gasoline engines), and combustion chambers. V6 engines have two cylinder heads, one for each bank.

- Valves: Control the flow of air and fuel into the cylinders (intake valves) and the exhaust gases out (exhaust valves). The timing and lift of the valves are critical for engine performance.

- Camshaft(s): Rotate and operate the valves through a system of lifters, pushrods (in some older designs), and rocker arms. Many modern engines use dual overhead camshafts (DOHC) for finer valve control.

- Intake Manifold: Distributes the air-fuel mixture to the cylinders.

- Exhaust Manifold: Collects the exhaust gases from the cylinders and directs them to the exhaust system.

- Fuel Injectors: Spray fuel into the intake manifold or directly into the cylinders (direct injection).

- Spark Plugs: In gasoline engines, ignite the air-fuel mixture to start the combustion process.

- Engine Block: The main structure of the engine, containing the cylinders, coolant passages, and oil passages.

- Oil Pan: Sits at the bottom of the engine and holds the engine oil.

Understanding Engine Diagram Symbols

Engine diagrams use standardized symbols to represent different components and systems. Here's a rundown of some common ones:

- Solid Lines: Generally represent mechanical connections, such as linkages, shafts, or rods.

- Dashed Lines: Often indicate vacuum lines or control signals.

- Dotted Lines: May represent electrical wiring or sensors.

- Arrows: Show the direction of flow (e.g., air, fuel, coolant, oil).

- Circles: Can represent various components, depending on what's inside the circle (e.g., a filter, a sensor).

- Rectangles: Commonly used for electronic control units (ECUs), relays, or switches.

- Colors: While not always consistent, colors can sometimes be used to differentiate systems. For example, blue might represent coolant lines, red for oil, and yellow for fuel. However, *always* refer to the diagram's legend for accurate color coding.

- Component-Specific Icons: These are visual representations of the actual components, such as a simplified drawing of a piston, valve, or spark plug.

How a 6-Cylinder Engine Works

Regardless of whether it's an inline-six or a V6, the basic operating principle is the same: the four-stroke combustion cycle. This cycle happens in each cylinder, and the timing of each cylinder's cycle is staggered to provide a smooth flow of power.

Here's a breakdown of the four strokes:

- Intake Stroke: The piston moves down, creating a vacuum. The intake valve opens, allowing the air-fuel mixture to be drawn into the cylinder.

- Compression Stroke: The intake valve closes, and the piston moves up, compressing the air-fuel mixture. This compression increases the mixture's temperature and pressure, making it easier to ignite.

- Combustion (Power) Stroke: At the top of the compression stroke, the spark plug ignites the compressed air-fuel mixture. The resulting explosion forces the piston down, producing power.

- Exhaust Stroke: The exhaust valve opens, and the piston moves up, pushing the burnt gases out of the cylinder and into the exhaust manifold.

The crankshaft converts the linear motion of the pistons into rotational motion, which is then transmitted through the transmission to the wheels. The precise timing of the valves and ignition is controlled by the engine's computer (ECU) to optimize performance and efficiency.

Real-World Use and Basic Troubleshooting

Understanding the 6-cylinder engine layout can significantly aid in troubleshooting common problems. Here are a few examples:

- Misfires: A misfire occurs when one or more cylinders fails to fire correctly. Knowing the cylinder layout allows you to pinpoint the affected cylinder and troubleshoot the ignition system (spark plug, coil), fuel injector, or compression in that specific cylinder.

- Rough Idling: Can be caused by vacuum leaks. Identifying the intake manifold and its connections makes it easier to locate potential leaks.

- Oil Leaks: Common leak points include valve cover gaskets, oil pan gasket, and crankshaft seals. Knowing the location of these components simplifies the search.

- Coolant Leaks: Look for leaks around the water pump, hoses, and radiator. Understanding the coolant flow path helps to trace the leak back to its source.

Example: You're experiencing a misfire on cylinder #3. By looking at an engine diagram, you can quickly identify the location of cylinder #3, then inspect its spark plug, ignition coil, and fuel injector. You might even perform a compression test on that cylinder to check for internal engine damage.

Safety Considerations

Working on any engine involves inherent risks. Here are some specific safety concerns when dealing with 6-cylinder engines:

- High Voltage: The ignition system generates very high voltage (tens of thousands of volts) to fire the spark plugs. Never touch spark plug wires or ignition coils while the engine is running or the ignition is on.

- Hot Surfaces: The exhaust manifold and other engine components can get extremely hot. Allow the engine to cool completely before working on it.

- Rotating Parts: Keep your hands and tools clear of moving parts, such as the crankshaft pulley and belts, when the engine is running.

- Fuel: Gasoline is highly flammable. Work in a well-ventilated area and avoid sparks or open flames when working with fuel.

- Pressure: The fuel system is under pressure. Relieve the pressure before disconnecting fuel lines.

Important: Always disconnect the negative battery cable before working on the electrical system or fuel system.

By understanding the basics of 6-cylinder engine configuration, you'll be better equipped to diagnose and repair your vehicle. Remember to consult your vehicle's repair manual for specific procedures and torque specifications.

To further assist you, we have prepared a comprehensive engine diagram covering both inline-six and V6 configurations, highlighting key components and systems. You can download the diagram here.