What Does A Car Actuator Do

Welcome, fellow gearheads! Today, we're diving deep into the world of car actuators – those unsung heroes that silently orchestrate many crucial functions within your vehicle. Understanding actuators is essential for diagnosing issues, performing repairs, or even planning modifications. Think of this article as your comprehensive guide to these often-overlooked components.

Purpose: Why Actuators Matter

Actuators are the muscles of your car's control system. They take electronic signals from the car's computer (ECU or PCM) and translate them into physical actions. This article is vital for several reasons:

- Troubleshooting: Identifying a faulty actuator is crucial for diagnosing issues like poor engine performance, transmission problems, or climate control malfunctions.

- Repair and Replacement: Understanding how actuators work helps you replace them correctly and avoid further damage.

- Modifications: If you're into performance modifications, understanding how actuators control aspects like turbo boost or fuel delivery is critical.

- General Knowledge: Knowing the roles of different actuators enhances your overall understanding of your car's systems.

Key Specs and Main Parts

While actuators vary in design and function, they generally share common components and specifications. Here's a breakdown:

Core Components:

- Control Unit (ECU/PCM): This is the "brain" that sends the signal to the actuator.

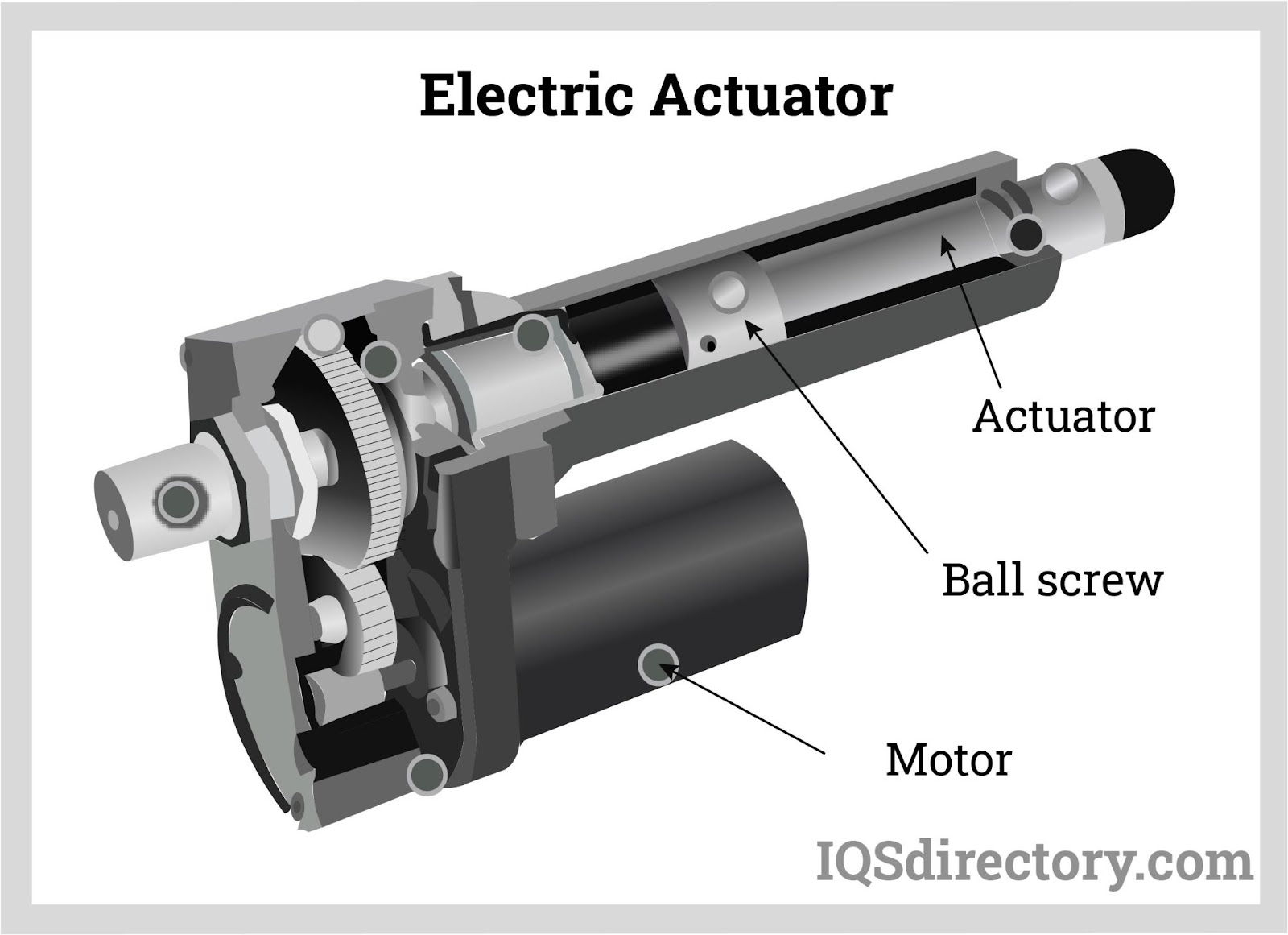

- Actuator Body: The main housing that contains the actuating mechanism.

- Electric Motor/Solenoid: The power source that drives the actuator. An electric motor provides rotational force, while a solenoid uses electromagnetic force for linear movement.

- Gear Train (if applicable): Used to amplify torque or convert rotational motion to linear motion (or vice-versa).

- Linkage/Arm: Connects the actuator to the component it controls (e.g., a throttle plate, a valve, or a door lock).

- Position Sensor (often): Provides feedback to the ECU about the actuator's position, allowing for precise control (closed-loop system). This is often a potentiometer or a Hall-effect sensor.

Key Specifications:

- Voltage: The operating voltage of the actuator (typically 12V DC in cars).

- Current Draw: The amount of current the actuator consumes during operation. Higher current draw can indicate a potential problem.

- Torque/Force: The amount of rotational force (torque) or linear force the actuator can generate.

- Operating Range: The range of motion or travel the actuator can achieve.

- Response Time: How quickly the actuator can respond to a command signal.

- Duty Cycle: For actuators controlled by Pulse-Width Modulation (PWM), the duty cycle represents the percentage of time the actuator is "on" versus "off" within a given period.

How It Works

The basic principle behind actuator operation is quite simple. The ECU receives information from various sensors about the engine's condition, driver input, and other factors. Based on this information, the ECU sends a control signal (usually a voltage or a PWM signal) to the actuator. The actuator then converts this electrical signal into mechanical motion to perform a specific task.

Let's illustrate with an example: the electronic throttle actuator. When you press the accelerator pedal, the ECU receives a signal from the accelerator pedal position sensor (APPS). The ECU then determines the desired throttle opening and sends a corresponding voltage to the throttle actuator. The actuator, which contains an electric motor, rotates a shaft that is connected to the throttle plate. As the shaft rotates, the throttle plate opens or closes, controlling the amount of air entering the engine.

Many actuators use feedback loops for precise control. In the throttle actuator example, a throttle position sensor (TPS) reports the actual throttle plate angle back to the ECU. The ECU compares the desired angle with the actual angle and adjusts the voltage to the actuator to maintain the desired throttle opening. This closed-loop control ensures accurate and responsive throttle control.

Another common type of actuator is the solenoid actuator. Solenoids use electromagnetic force to move a plunger or valve. When current flows through the solenoid coil, a magnetic field is created, pulling the plunger into the coil. This linear motion can be used to control valves in the fuel system, transmission, or other components.

Real-World Use: Basic Troubleshooting Tips

Here are some basic troubleshooting steps you can take if you suspect a faulty actuator:

- Check for Codes: Use an OBD-II scanner to check for diagnostic trouble codes (DTCs) related to the actuator. Common codes might indicate a short circuit, open circuit, or performance issue.

- Visual Inspection: Inspect the actuator for any signs of physical damage, such as cracks, broken connectors, or corrosion.

- Wiring Check: Inspect the wiring harness and connectors leading to the actuator for any signs of damage or loose connections. Use a multimeter to check for continuity and voltage at the actuator connector.

- Power Supply Check: Verify that the actuator is receiving the correct voltage from the ECU.

- Actuator Resistance Test: Use a multimeter to measure the resistance of the actuator coil (for solenoid actuators) or the motor winding (for electric motor actuators). An unusually high or low resistance reading can indicate a problem. Consult the service manual for the specified resistance range.

- Functional Test: Some scan tools allow you to activate the actuator directly to test its functionality. For example, you can command the throttle actuator to open and close the throttle plate and observe its response.

- Listen: Sometimes, you can hear an actuator failing. A clicking sound when it should be a smooth movement can indicate an issue.

Example Troubleshooting Scenario: Your car has a code indicating a problem with the EGR (Exhaust Gas Recirculation) valve actuator. You first visually inspect the actuator and its wiring for any obvious damage. You then use a multimeter to check for voltage at the actuator connector. If voltage is present, you can try using a scan tool to activate the EGR valve and observe its movement. If the valve doesn't move or moves erratically, the actuator is likely faulty and needs to be replaced.

Safety: Highlight Risky Components

Working with electrical components always presents some risks. Here are a few safety precautions to keep in mind when working with actuators:

- Disconnect the Battery: Before working on any electrical components, disconnect the negative terminal of the battery to prevent accidental shorts or electrical shocks.

- Avoid Working on Live Circuits: Unless specifically instructed to do so for diagnostic purposes, avoid working on live circuits. Always disconnect the power supply before disconnecting or reconnecting connectors.

- Use Proper Tools: Use insulated tools and wear appropriate safety gear, such as gloves and eye protection.

- Be Careful with High-Pressure Systems: Some actuators, such as those used in brake systems or fuel injection systems, may be connected to high-pressure lines. Be extremely careful when disconnecting these lines to avoid injury. Refer to the service manual for specific instructions.

- Consult the Service Manual: Always consult the service manual for your specific vehicle before working on any components. The service manual will provide detailed instructions, diagrams, and safety precautions.

Specifically, Fuel Injector Actuators can be risky due to the high fuel pressures involved. Improper handling can result in fuel spray, which is flammable and potentially dangerous.

Similarly, ABS (Anti-lock Braking System) Actuators can retain pressure even after the vehicle is turned off. Depressurizing the system properly is essential before working on it.

Always double-check wiring diagrams before reconnecting any actuators to avoid damaging the ECU or the actuator itself.

Actuators are integral to the operation of modern vehicles, controlling everything from engine performance to comfort features. By understanding their function, troubleshooting techniques, and safety considerations, you can confidently diagnose and repair actuator-related issues, enhancing your DIY capabilities and saving money on costly repairs.

To further assist you, we have a detailed actuator wiring diagram available for download. This diagram provides a visual representation of actuator connections and will be a valuable resource for your troubleshooting and repair efforts.

We hope this guide has empowered you with a solid understanding of car actuators. Happy wrenching!