What Does A Car Transmission Do

Alright, let's dive into the heart of your car's drivetrain: the transmission. Whether you're planning a clutch replacement, diagnosing a shifting issue, or just expanding your automotive knowledge, understanding how a transmission works is crucial. This article will break down the inner workings of both manual and automatic transmissions, equipping you with the knowledge to tackle basic repairs and maintenance.

Purpose: Why This Matters

Understanding the transmission is more than just academic. It's essential for:

- Diagnosis: Identifying the root cause of shifting problems, noises, or performance issues.

- Repair: Performing basic repairs like fluid changes, filter replacements, and even more involved tasks like clutch replacements (manual transmissions) or valve body work (automatic transmissions).

- Modification: Planning drivetrain upgrades, such as swapping transmissions, installing a performance clutch, or re-gearing differentials.

- Preventative Maintenance: Catching problems early and extending the life of your transmission by understanding its operating principles.

We'll cover both manual and automatic transmissions, highlighting the key differences and similarities.

Key Specs and Main Parts

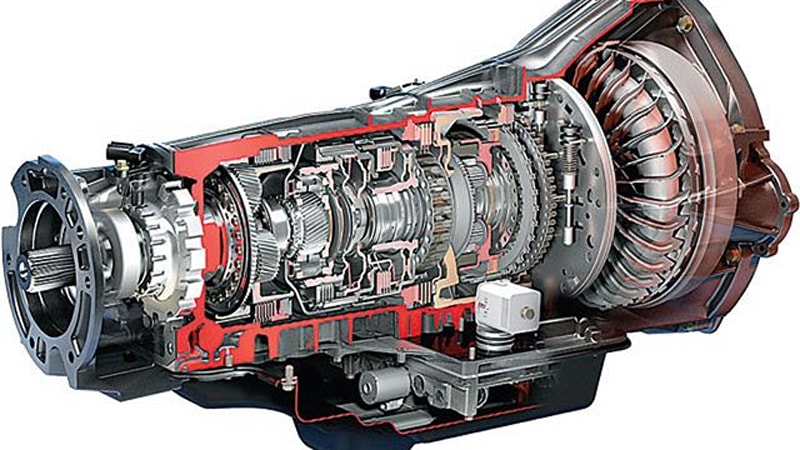

The transmission's primary job is to multiply the engine's torque and deliver it to the wheels at an appropriate speed. Here's a breakdown of the main components:

Manual Transmission

- Input Shaft: Connected to the engine via the clutch. It spins at engine speed.

- Clutch: Disconnects the engine from the transmission, allowing for gear changes. Consists of a pressure plate, friction disc, and release bearing.

- Gears: Different sized gears on the main shaft and countershaft provide various gear ratios.

- Countershaft (or Layshaft): A shaft that contains gears that are always meshed with the main shaft gears.

- Main Shaft (or Output Shaft): Connected to the driveshaft, delivering power to the wheels.

- Synchronizers: Cone-shaped devices that equalize the speed of the gears before they engage, preventing grinding.

- Shift Forks: Move the synchronizers to engage different gears.

- Shift Linkage: Connects the gear shift lever in the cabin to the shift forks in the transmission.

Automatic Transmission

- Torque Converter: Replaces the clutch. It uses fluid to transfer power from the engine to the transmission. Think of it as a fluid coupling that also provides some torque multiplication.

- Planetary Gear Sets: Complex arrangements of gears (sun gear, planet gears, ring gear) that provide different gear ratios.

- Clutches and Bands: Engage and disengage planetary gear sets to change gears. These are hydraulically controlled.

- Valve Body: The "brain" of the automatic transmission. It contains valves that control the flow of hydraulic fluid to the clutches and bands, based on inputs like throttle position, vehicle speed, and shift lever position.

- Transmission Control Module (TCM): In modern vehicles, the TCM is a computer that controls the valve body.

- Output Shaft: Connected to the driveshaft.

How It Works

Manual Transmission Operation

The engine's power enters the transmission through the input shaft. When you press the clutch pedal, you disconnect the engine from the input shaft. You then move the shift lever, which moves the shift forks. The shift forks engage synchronizers, which smoothly mesh the desired gear with the output shaft. Releasing the clutch pedal re-engages the engine, and power flows through the selected gear ratio to the output shaft and then to the wheels.

Different gear ratios provide different levels of torque multiplication. Lower gears (e.g., 1st and 2nd) provide more torque for acceleration, while higher gears (e.g., 5th or 6th) provide better fuel economy at cruising speeds.

Automatic Transmission Operation

In an automatic transmission, the torque converter continuously transfers power from the engine. Inside the transmission, planetary gear sets provide different gear ratios. The valve body, controlled by hydraulic pressure and often a TCM, engages and disengages clutches and bands to select the appropriate gear ratio. For example, when accelerating, the TCM will signal the valve body to engage the clutches and bands that correspond to first gear. As you accelerate further, the TCM will signal the valve body to shift to second gear, and so on.

Real-World Use: Basic Troubleshooting Tips

Here are a few common transmission problems and potential solutions:

- Manual Transmission: Grinding gears: This often indicates worn synchronizers. Try double-clutching (depressing the clutch, shifting to neutral, releasing the clutch, pressing the clutch again, and shifting into the desired gear) as a temporary workaround. Ultimately, synchronizer replacement is often required.

- Manual Transmission: Difficulty shifting: Could be a problem with the clutch linkage, a worn clutch, or low transmission fluid.

- Automatic Transmission: Slipping: The engine revs high, but the car doesn't accelerate properly. This usually indicates worn clutches or bands inside the transmission. A transmission rebuild is often required.

- Automatic Transmission: Harsh shifting: Can be caused by low transmission fluid, a faulty valve body, or a failing TCM. Check the fluid level and condition first. If the fluid is dark or smells burnt, it needs to be changed.

- Both: Leaks: Check for leaks around the transmission housing, seals, and lines. Address leaks promptly to prevent low fluid levels and further damage.

- Both: Noisy Transmission: Whining, humming, or clunking sounds can indicate bearing wear or gear damage. Ignoring these noises can lead to catastrophic failure.

Safety

Working on transmissions involves several safety considerations:

- Lifting and Supporting the Vehicle: Always use jack stands on a level surface. Never work under a vehicle supported only by a jack.

- Transmission Fluid: Transmission fluid can be hot. Allow the transmission to cool down before draining the fluid. Also, some older fluids may contain harmful chemicals. Wear gloves and eye protection.

- Springs and Retaining Rings: Some transmission components, like clutch springs in manual transmissions and snap rings in both types, are under significant tension. Use appropriate tools to compress springs and remove retaining rings to prevent injury.

- Heavy Components: Transmissions are heavy. Use a transmission jack to safely remove and install them.

- Electrical Components (Automatic Transmissions): Disconnect the battery before working on electrical components like the TCM or solenoids in the valve body.

Always consult a repair manual specific to your vehicle before attempting any repairs. A service manual provides detailed instructions, torque specifications, and safety precautions.

Warning: Improperly installed transmissions or incorrect torque specifications can lead to serious accidents. If you're unsure about any aspect of the repair, consult a qualified mechanic.

Having a detailed diagram can be invaluable.