What Does A Cvt Transmission Do

Continuously Variable Transmissions (CVTs) have moved from niche applications to become increasingly common in modern vehicles. Understanding how a CVT works is crucial for any serious DIY mechanic, car owner looking to perform preventative maintenance, or anyone contemplating modifications to their vehicle. This article will provide a detailed breakdown of CVT operation, key components, and troubleshooting tips, similar to how a seasoned mechanic would explain it to a knowledgeable DIYer.

Purpose: Why Learn About CVTs?

This information is valuable for several reasons:

- Repairs and Maintenance: Knowing how a CVT operates is essential for diagnosing problems, performing fluid changes correctly, and understanding when more serious repairs are needed.

- Performance Tuning: Understanding the CVT's control logic can help in modifying or optimizing vehicle performance (though modifications are generally *not* recommended for CVTs without expert knowledge).

- Informed Purchasing Decisions: If you’re buying a new or used car, understanding the transmission type will allow you to assess its reliability and potential maintenance costs.

- Avoiding Costly Mistakes: Proper fluid types, fill levels, and maintenance schedules are critical for CVT longevity. Understanding the system reduces the risk of damaging the transmission.

Key Specs and Main Parts

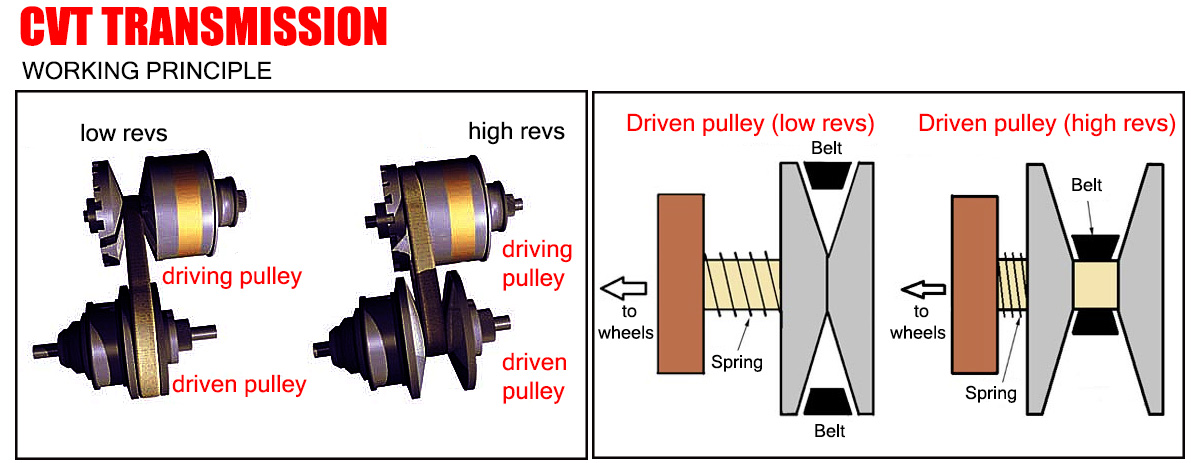

A CVT differs significantly from a traditional automatic transmission, which uses a set of gears to provide discrete gear ratios. Instead, a CVT uses a system of pulleys and a belt or chain to create a virtually infinite number of gear ratios within its design range.

Main Components:

- Input Shaft: Connected to the engine, it delivers engine torque to the CVT.

- Primary Pulley (Drive Pulley): This pulley is connected to the input shaft and varies its diameter to change the gear ratio.

- Secondary Pulley (Driven Pulley): This pulley is connected to the output shaft and also varies its diameter, working in conjunction with the primary pulley.

- Belt or Chain: A specialized high-strength belt or chain connects the two pulleys, transmitting power from the primary to the secondary. This is a critical component subjected to significant stress.

- Hydraulic Control System: A complex system of valves and solenoids controls the hydraulic pressure that actuates the pulleys, changing their diameters and thus the gear ratio.

- ECU (Engine Control Unit) / TCU (Transmission Control Unit): The ECU, or often a dedicated TCU, monitors various sensors (speed, throttle position, engine load, etc.) and controls the hydraulic system to optimize gear ratio based on driving conditions.

- Torque Converter (Often): Many CVTs, though not all, still utilize a torque converter to provide smooth starts from a standstill, and to multiply torque at low speeds, much like a traditional automatic transmission. Some modern CVTs use a wet clutch pack in place of a torque converter.

- Sensors: Speed sensors, pressure sensors, and temperature sensors provide feedback to the ECU/TCU for precise control.

Key Specs to Consider:

- Ratio Range: The difference between the lowest and highest gear ratios the CVT can achieve. A wider range allows for better acceleration and fuel economy.

- Torque Capacity: The maximum amount of torque the CVT can handle without damage. Exceeding this limit can lead to premature failure.

- Fluid Type: Extremely important. Use only the specified fluid. Using the wrong fluid can lead to rapid CVT failure.

How It Works

The core principle behind a CVT is the ability to continuously vary the gear ratio. Imagine two cones facing each other, connected by a belt. By moving the belt along the cones, you change the effective diameters of the pulleys, thereby changing the gear ratio. CVTs use variable-diameter pulleys instead of fixed cones, but the principle is the same. Let's break down the process:

- Engine Power: The engine's rotational force (torque) is delivered to the input shaft and then to the primary pulley.

- Pulley Adjustment: The ECU/TCU monitors various sensors and determines the optimal gear ratio. Based on this, it sends signals to the hydraulic control system.

- Hydraulic Pressure: The hydraulic control system uses precisely controlled hydraulic pressure to move the pulley faces closer together or further apart. This changes the effective diameter of the pulley.

- Ratio Change: As the diameter of the primary pulley changes, the belt/chain is forced to ride higher or lower on the pulley. This, in turn, affects the diameter of the secondary pulley. The ratio between these two diameters determines the overall gear ratio.

- Power Delivery: The rotational force is transferred from the secondary pulley to the output shaft, which drives the wheels.

Simulating Gear Changes: Many modern CVTs are programmed to simulate traditional gear shifts. This is often done to provide a more familiar driving experience, as some drivers find the constant engine speed of a "true" CVT disconcerting. The simulated shifts are achieved by rapidly changing the gear ratio to mimic the feel of a gear change.

Real-World Use – Basic Troubleshooting Tips

CVTs are generally reliable, but like any mechanical system, they can experience problems. Here are some common issues and basic troubleshooting steps:

- Slipping: The engine revs high but the car doesn't accelerate properly. This could be due to low fluid level, worn belt/chain, or internal damage. Check the fluid level and condition first. If the fluid is dark or burnt, it needs to be replaced.

- Jerky or Erratic Shifting: This could be caused by a faulty sensor, a problem with the hydraulic control system, or damaged pulleys. A diagnostic scan may reveal sensor issues.

- Noise: Whining or buzzing noises can indicate worn bearings or damaged internal components. This usually requires professional diagnosis.

- Warning Lights: The "Check Engine" or "Transmission" light may illuminate. Get the vehicle scanned for diagnostic trouble codes (DTCs).

Important Note: CVT repairs are often complex and require specialized tools and knowledge. For serious issues, it's best to consult a qualified technician.

Safety – Highlight Risky Components

Working on a CVT can be dangerous if proper precautions are not taken.

- High-Pressure Fluid: The hydraulic control system operates at high pressure. Be careful when disconnecting lines or components to avoid injury from spraying fluid.

- Hot Components: The CVT can get very hot during operation. Allow the transmission to cool down completely before working on it.

- Lifting and Support: If you need to lift the vehicle to access the transmission, use jack stands to securely support the vehicle. Never work under a vehicle supported only by a jack.

- Fluid Disposal: Dispose of used transmission fluid properly according to local regulations.

CVT Belt/Chain: The belt/chain is under tremendous tension. Do not attempt to disassemble the CVT without proper training and specialized tools. Improper handling can result in serious injury.

This article provides a solid foundation for understanding CVT operation. Remember that diagnosis and repair can be complex. Always refer to the vehicle's service manual for specific procedures and torque specifications. With careful study and the right resources, you can expand your understanding of CVT technology and confidently tackle maintenance tasks.

We have a detailed diagram of a typical CVT that you can download for further study. This diagram provides a visual representation of the components and their interactions, which can be helpful in understanding the system. Contact us for more information on how to access this file.