What Does A Cvt Transmission Mean

So, you're diving into the world of Continuously Variable Transmissions, or CVTs. Smart move! They're becoming increasingly common, and understanding how they work is crucial for any serious DIY mechanic or car enthusiast. This isn't your granddad's automatic; CVTs have some unique quirks and advantages. This article will give you the technical lowdown, explaining the key components, how they function, and what you need to know for basic troubleshooting. Think of me as your trusted mechanic, giving you the inside scoop.

Purpose: Why Understanding CVTs Matters

Knowing the ins and outs of a CVT is beneficial for several reasons:

- Troubleshooting and Diagnosis: CVTs have failure modes that are distinct from traditional automatics. Understanding the symptoms and their causes allows for more accurate diagnosis.

- Repair and Maintenance: While full CVT overhauls are often best left to specialists, preventative maintenance, such as fluid changes, is critical. Knowing how the transmission operates helps you perform these tasks correctly.

- Performance Tuning (with caveats): While CVTs aren't typically favored for high-performance applications, understanding their limitations and capabilities can help you optimize their performance within safe operating parameters. Note that modification can be risky and void warranties.

- Understanding Vehicle Behavior: Knowing how the CVT controls the engine's RPMs relative to vehicle speed can help you understand why your car behaves the way it does in different driving situations.

Key Specs and Main Parts

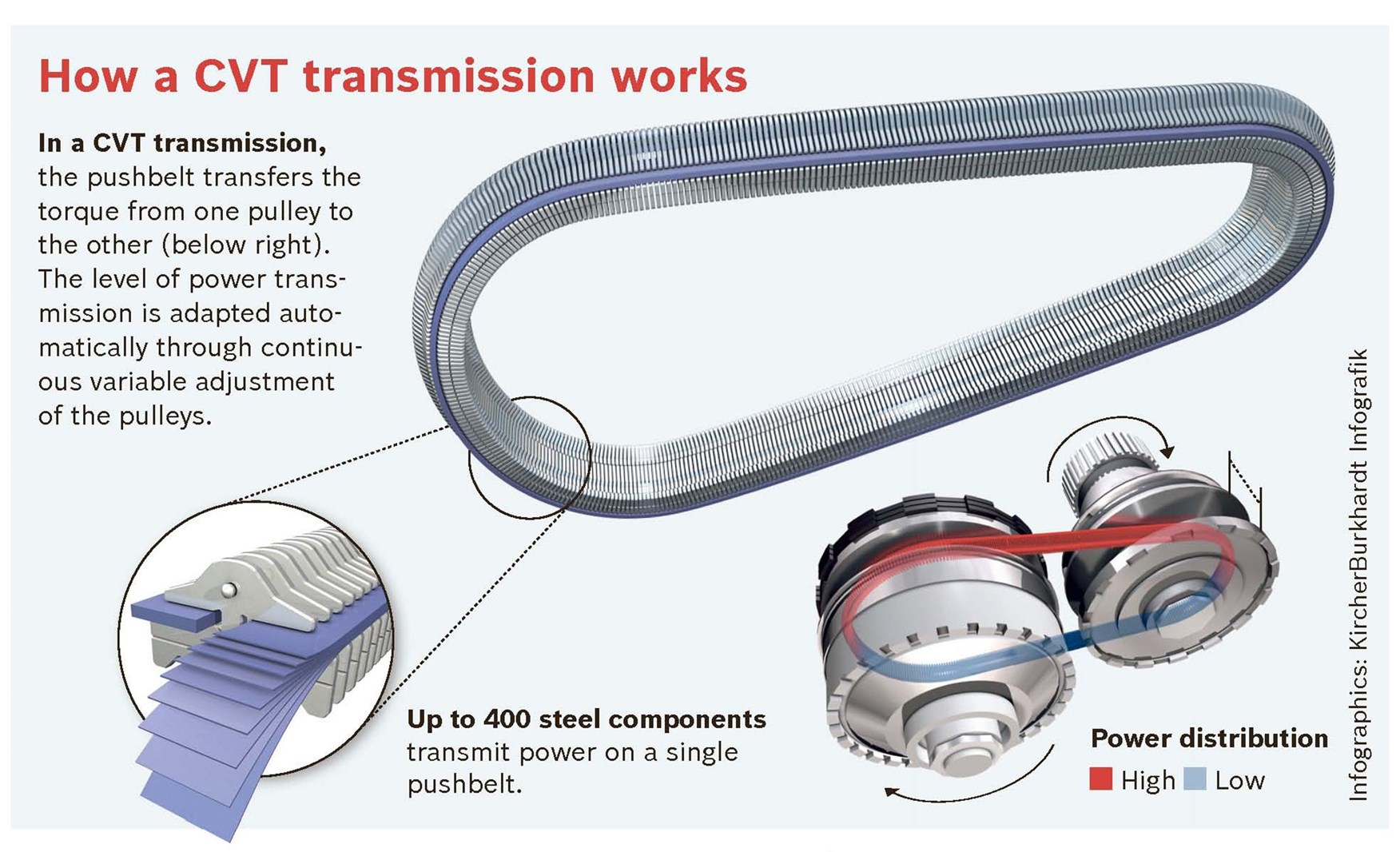

The core of a CVT is its ability to provide a seemingly infinite number of gear ratios between a minimum and maximum value. Unlike traditional transmissions with fixed gears, a CVT uses a system of pulleys and a belt or chain to achieve this.

Main Components:

- Input Pulley (Driving Pulley): Connected to the engine, this pulley's diameter can change.

- Output Pulley (Driven Pulley): Connected to the wheels, this pulley also has a variable diameter.

- Belt or Chain: A specialized, high-strength belt or chain connects the two pulleys, transmitting power between them. This is a critical component designed to withstand immense tensile and compressive forces.

- Hydraulic Control System: A complex system of valves, solenoids, and sensors that controls the hydraulic pressure to the pulleys, dictating their diameter and thus the gear ratio. This is often managed by the Transmission Control Module (TCM).

- Transmission Control Module (TCM): The "brain" of the CVT, receiving input from various sensors (engine speed, vehicle speed, throttle position, etc.) and controlling the hydraulic system to achieve the desired gear ratio.

- Forward/Reverse Mechanism: While some CVTs use a traditional planetary gearset for reverse, others employ a more compact system integrated into the overall design.

- Torque Converter (or Fluid Coupling): Similar to automatic transmissions, a torque converter provides smooth initial engagement and torque multiplication at low speeds. Some CVTs utilize a fluid coupling instead, depending on design and application.

- Oil Pump: Provides the necessary hydraulic pressure for the system.

How It Works

The beauty of a CVT lies in its simple principle: by varying the effective diameters of the input and output pulleys, the transmission can achieve any gear ratio within its design limits. Imagine two cones facing each other, with a belt running between them. If the belt is near the wide end of the first cone (input pulley) and the narrow end of the second cone (output pulley), you have a low gear ratio – high torque, low speed. Conversely, if the belt is near the narrow end of the first cone and the wide end of the second cone, you have a high gear ratio – low torque, high speed.

In practice, the pulleys aren't cones, but rather sets of conical discs that can move closer together or further apart. Hydraulic pressure controls the spacing between these discs. Increasing the pressure on one pulley forces the discs closer together, increasing its effective diameter, while simultaneously decreasing the pressure on the other pulley, decreasing its diameter.

The TCM is responsible for managing this process. It monitors driver inputs (throttle position, brake application) and vehicle conditions (speed, load) to determine the optimal gear ratio. It then signals the hydraulic control system to adjust the pulley diameters accordingly. The result is seamless and continuous gear ratio changes, without the distinct "shifts" of a traditional automatic transmission.

Real-World Use – Basic Troubleshooting Tips

CVTs are generally reliable, but they can suffer from specific problems. Proper fluid maintenance is paramount.

- Slipping: A common symptom of a worn belt or chain, or low fluid level. This feels like the engine is revving without a corresponding increase in speed. Check the fluid level first! If the fluid is full and in good condition, the belt/chain may be worn and require replacement.

- Jerky Acceleration: Can be caused by a malfunctioning solenoid or valve in the hydraulic control system. A diagnostic scan tool can often pinpoint the faulty component.

- Hesitation: Similar to slipping, but less pronounced. Could indicate a partially clogged filter or low fluid pressure.

- Unusual Noises: Grinding or whining noises are serious and could indicate bearing failure or internal damage. Stop driving immediately and consult a qualified technician.

- Error Codes: The TCM will often store diagnostic trouble codes (DTCs) related to CVT problems. Use a scan tool to retrieve these codes and research their meaning.

Before attempting any repairs, consult your vehicle's service manual. Always use the correct CVT fluid specified by the manufacturer. Using the wrong fluid can cause serious damage.

Safety – Highlight Risky Components

Working on a CVT requires caution due to the high hydraulic pressures involved and the potential for component failure. Here are some safety considerations:

- Hydraulic Pressure: The hydraulic system operates at very high pressure. Depressurize the system according to the service manual before disconnecting any lines or components. Failure to do so can result in serious injury.

- Belt/Chain Tension: The belt or chain is under immense tension. Never attempt to disassemble the transmission without the proper tools and procedures to safely release this tension.

- Fluid Handling: CVT fluid can be hot and messy. Wear appropriate safety glasses and gloves. Dispose of used fluid properly.

- Weight: Transmissions are heavy. Use a transmission jack or other appropriate lifting equipment to prevent injury.

- Complexity: CVT repair is complex and often requires specialized tools and knowledge. If you are not comfortable with the procedure, it is best to consult a qualified technician.

Always disconnect the negative battery terminal before working on any electrical components. This prevents accidental short circuits and potential damage to the TCM.

Remember, while this guide provides a foundational understanding of CVT transmissions, it is not a substitute for professional training or experience. If you're unsure about any aspect of CVT repair or maintenance, seek the advice of a qualified technician.