What Does A Drive Belt Do

So, you're diving into the world of drive belts, huh? Good on you. Understanding this system is crucial for maintaining your car's reliability and performance. This knowledge empowers you to diagnose issues, perform preventative maintenance, and even tackle some repairs yourself, saving you time and money. We're going to break down exactly what a drive belt does, the components involved, how it all works, and even some troubleshooting tips to get you started. We'll also cover essential safety precautions because, let's face it, working around a running engine requires respect and caution.

Purpose and Importance

The drive belt, sometimes called the serpentine belt, is a critical component in your vehicle's engine. Its primary purpose is to transfer rotational power from the engine's crankshaft to various auxiliary components. Think of it as a crucial link in a chain that keeps your car running smoothly. Without a functioning drive belt, several essential systems would cease to operate, leading to immediate or eventual failure.

Key Specs and Main Parts

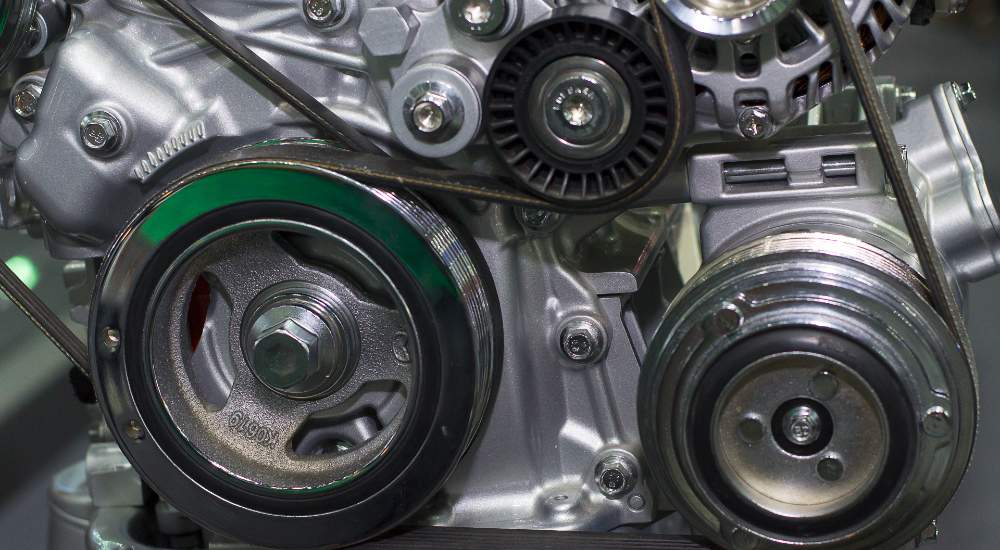

Let's look at the main players in the drive belt system:

- Crankshaft Pulley: This pulley is directly connected to the crankshaft, the rotating axis of the engine. It's the source of the power that drives the entire system.

- Alternator: The alternator generates electrical power to charge the battery and run the electrical components in your vehicle (lights, radio, etc.). The drive belt spins its pulley, enabling it to produce electricity.

- Water Pump: The water pump circulates coolant throughout the engine, preventing overheating. The drive belt is often responsible for driving the water pump, keeping your engine at the correct operating temperature.

- Power Steering Pump: This pump provides hydraulic assistance to the steering system, making it easier to turn the wheel. In many vehicles, the drive belt powers the power steering pump.

- Air Conditioning (A/C) Compressor: The A/C compressor is responsible for compressing the refrigerant in the air conditioning system, allowing it to cool the cabin. It's often driven by the drive belt.

- Idler Pulley(s): These pulleys provide tension and guide the drive belt along its intended path. They don't directly power any component but are essential for maintaining proper belt alignment and tension.

- Tensioner Pulley: This spring-loaded pulley automatically maintains the correct tension on the drive belt. It compensates for belt stretching and wear over time. A faulty tensioner can lead to belt slippage and premature wear.

- The Drive Belt: The belt itself is usually made from a reinforced rubber compound. It's designed to be durable and resistant to heat, oil, and abrasion. Serpentine belts, the most common type, feature multiple ribs that grip the pulleys effectively. V-belts, an older design, have a trapezoidal cross-section.

Important Specs to Consider:

- Belt Length: Measured in inches or millimeters. The correct length is critical for proper tension and function. Your vehicle's manufacturer specifies the appropriate length.

- Belt Width: Also measured in inches or millimeters. Ensures proper fit within the pulley grooves.

- Number of Ribs: Serpentine belts have multiple ribs that engage with the grooves on the pulleys. The correct number of ribs is crucial for optimal grip.

How It Works

The drive belt system is a marvel of mechanical efficiency. The crankshaft, driven by the engine's combustion, spins its pulley. This rotational force is then transferred to the drive belt. As the crankshaft pulley rotates, it pulls the drive belt along with it. The belt, in turn, wraps around and spins the pulleys of the other components (alternator, water pump, power steering pump, A/C compressor). Because the belt is under tension, it can effectively transmit the rotational force from the crankshaft to these auxiliary components.

The tensioner pulley plays a vital role in maintaining the correct belt tension. If the belt is too loose, it will slip, reducing the efficiency of the driven components and potentially causing damage. If the belt is too tight, it can put excessive stress on the bearings of the driven components, leading to premature failure. The tensioner automatically adjusts to maintain the optimal balance.

Real-World Use - Basic Troubleshooting Tips

Here are some common symptoms indicating a problem with your drive belt system:

- Squealing or Chirping Noise: This is often a sign of a slipping belt, usually caused by looseness or wear.

- Battery Light On: If the alternator isn't being driven properly due to a slipping or broken belt, the battery won't charge, and the battery light will illuminate.

- Overheating: If the water pump isn't circulating coolant effectively, your engine can overheat. A failing drive belt could be the culprit.

- Loss of Power Steering: If the power steering pump stops working, you'll notice a significant increase in steering effort.

- No Cold Air: If the A/C compressor isn't being driven, the air conditioning system won't produce cold air.

- Visible Belt Damage: Cracks, fraying, missing chunks, or excessive wear on the belt are clear signs that it needs to be replaced.

Basic Troubleshooting Steps:

- Visual Inspection: Carefully examine the drive belt for any signs of damage.

- Belt Tension Check: Check the belt tension using a belt tension gauge or by manually checking the deflection (the amount the belt can be pushed in). Consult your vehicle's repair manual for the correct tension specification.

- Pulley Alignment: Ensure that all the pulleys are properly aligned. Misalignment can cause premature belt wear and failure. Use a straight edge to check alignment.

- Tensioner Operation: Inspect the tensioner pulley for smooth and proper operation. It should move freely without binding or excessive play.

Important Note: If you're not comfortable performing these checks yourself, it's always best to consult a qualified mechanic.

Safety - Highlight Risky Components

Working around a running engine presents several safety hazards. Here are some key precautions to take:

- Never work on the drive belt system with the engine running unless absolutely necessary for diagnostic purposes. If you must run the engine, exercise extreme caution.

- Keep your hands, hair, and clothing away from the moving parts of the drive belt system. The rotating pulleys and belt can cause serious injury.

- Disconnect the negative battery terminal before working on any electrical components. This will prevent accidental shocks and damage to the electrical system.

- Wear safety glasses to protect your eyes from flying debris.

- Use the correct tools for the job. Using the wrong tools can damage components and increase the risk of injury.

- Be aware that engine components can get very hot. Allow the engine to cool down before working on it.

The drive belt system might seem simple, but it's a vital part of your car. Understanding its function and components will empower you to diagnose problems, perform maintenance, and keep your car running smoothly. Remember to prioritize safety and consult a professional when in doubt.