What Does A Fuel Regulator Do

Let's dive into the world of fuel regulation – a critical component in your car's fuel system. Whether you're chasing better performance, diagnosing a fuel delivery issue, or just expanding your automotive knowledge, understanding the fuel regulator is essential. This article will equip you with the knowledge to confidently navigate fuel system diagnostics and modifications.

Purpose of Understanding Fuel Regulation

Why bother learning about fuel regulators? Several reasons stand out. First, it's crucial for diagnosing and repairing fuel-related issues, such as poor fuel economy, rough idling, or a complete no-start condition. Second, if you're considering performance modifications, such as upgrading your fuel injectors or adding a turbocharger, understanding how the fuel regulator manages fuel pressure is paramount for preventing engine damage. Finally, having a solid grasp of fuel regulation allows for safe and effective DIY repairs, saving you money and increasing your self-reliance.

Key Specs and Main Parts

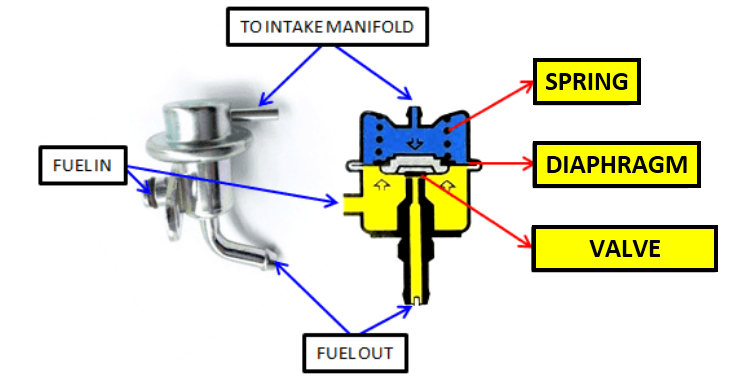

The fuel regulator's primary job is to maintain a constant fuel pressure differential across the fuel injectors. This ensures consistent fuel delivery regardless of engine load or RPM. Let’s break down the key components:

- Diaphragm: A flexible membrane that responds to pressure changes within the fuel rail and the intake manifold. Think of it like a tiny pressure-sensing drum.

- Spring: Provides a constant force against the diaphragm, setting the base fuel pressure. Different spring rates will result in different base fuel pressures.

- Fuel Inlet: Where fuel enters the regulator, typically directly from the fuel rail.

- Fuel Outlet/Return Line: Allows excess fuel to return to the fuel tank, preventing over-pressurization.

- Vacuum/Boost Reference Port: Connects to the intake manifold, allowing the regulator to adjust fuel pressure based on engine vacuum or boost (in turbocharged applications). This is critical for maintaining a consistent pressure differential.

- Valve: Controls the flow of fuel through the return line, adjusting the pressure in the fuel rail.

Key Specifications: Fuel regulators are often characterized by their base pressure (the pressure they maintain at idle or with no vacuum applied) and their adjustability range. Base pressure is typically measured in PSI (pounds per square inch) or Bar. Adjustable fuel regulators allow you to fine-tune the fuel pressure to optimize performance, especially after modifications.

Understanding Fuel System Diagram Symbols

Let's demystify common symbols found in fuel system diagrams:

- Solid Lines: Typically represent fuel lines carrying pressurized fuel.

- Dashed Lines: Usually indicate vacuum lines or signal lines.

- Arrows: Show the direction of fuel or vacuum flow.

- Fuel Pump Symbol: A stylized representation of the fuel pump, often resembling a small turbine.

- Fuel Filter Symbol: Usually a rectangular or cylindrical shape with an internal filter element.

- Fuel Injector Symbol: Often depicted as a nozzle with a small electrical connector.

- Fuel Pressure Regulator Symbol: Can vary, but often includes a diaphragm symbol and connections for fuel inlet, outlet, and vacuum/boost reference.

Colors are less standardized, but often red is used to indicate high-pressure fuel lines.

How It Works: The Dance of Pressure and Vacuum

Here’s the breakdown of how a typical fuel pressure regulator operates:

- Fuel Delivery: The fuel pump sends fuel to the fuel rail, which supplies the injectors.

- Pressure Build-Up: As fuel enters the fuel rail, pressure builds up.

- Regulator Activation: The fuel regulator monitors the pressure in the fuel rail. The spring inside the regulator exerts a force against the diaphragm, trying to keep the valve closed.

- Pressure Regulation: When the fuel pressure exceeds the force of the spring, the diaphragm moves, opening the valve to the return line.

- Excess Fuel Return: Excess fuel flows through the return line back to the fuel tank, preventing over-pressurization of the fuel rail.

- Vacuum Compensation: The vacuum/boost reference port connected to the intake manifold allows the regulator to adjust fuel pressure based on engine load. At idle, high vacuum pulls on the diaphragm, reducing fuel pressure. Under boost, the positive pressure increases fuel pressure. This ensures a consistent fuel pressure differential across the injectors, regardless of engine conditions.

The key concept here is the pressure differential. The fuel regulator maintains a constant pressure difference between the fuel rail and the intake manifold. This means the injectors "see" a consistent fuel pressure, allowing them to deliver the correct amount of fuel based on the injector pulse width (the duration the injector is open).

Real-World Use: Basic Troubleshooting

Here are a few basic troubleshooting tips related to the fuel regulator:

- High Fuel Pressure: Can be caused by a stuck-closed fuel regulator, a kinked return line, or a faulty fuel pump (though this is less common). Symptoms include poor fuel economy, rough idling, and potentially fuel leaking from the injectors.

- Low Fuel Pressure: Can be caused by a stuck-open fuel regulator, a leak in the fuel system, a weak fuel pump, or a clogged fuel filter. Symptoms include poor acceleration, stalling, and a no-start condition.

- Vacuum Line Issues: Check the vacuum line connecting the regulator to the intake manifold for leaks or cracks. A disconnected or leaking vacuum line can cause incorrect fuel pressure and driveability issues. A cracked or hardened vacuum line will not transmit vacuum accurately.

- Testing Fuel Pressure: A fuel pressure gauge is your best friend. Connect it to the test port on the fuel rail and check the fuel pressure at idle and under load. Compare the readings to the manufacturer's specifications.

- Smell of Fuel: Investigate any fuel odors immediately. Could be regulator diaphragm failure which will likely result in fuel entering the vacuum line and the engine.

Simple Check: Disconnect the vacuum line from the fuel regulator. The fuel pressure should increase. If it doesn't, the regulator might be faulty.

Safety: A Word of Caution

Working with fuel systems involves inherent risks. Fuel is highly flammable, and pressurized fuel can be dangerous. Always take the following precautions:

- Disconnect the Battery: Before working on any fuel system component, disconnect the negative terminal of the battery to prevent sparks.

- Work in a Well-Ventilated Area: Ensure adequate ventilation to prevent the buildup of flammable vapors.

- Wear Safety Glasses: Protect your eyes from fuel spray.

- Use Appropriate Tools: Use fuel-resistant hoses and fittings, and avoid using tools that could create sparks.

- Relieve Fuel Pressure: Before disconnecting any fuel lines, relieve the fuel pressure. This can be done by disconnecting the fuel pump relay and starting the engine (it will stall after a few seconds). Some vehicles also have a fuel pressure relief valve on the fuel rail.

- Handle Fuel Carefully: Clean up any spills immediately with absorbent materials.

- Avoid Smoking or Open Flames: Absolutely no smoking or open flames near the fuel system.

The fuel pump and fuel rail are under significant pressure. Always relieve the pressure before disconnecting any components. A ruptured fuel line can spray fuel at high velocity, potentially causing serious injury.

By following these safety precautions and understanding the principles of fuel regulation, you can confidently diagnose and repair fuel system issues. Remember to consult your vehicle's repair manual for specific procedures and specifications.

We have a detailed fuel system diagram available for download. This diagram provides a visual representation of the fuel system, including the fuel regulator, fuel pump, fuel injectors, and other key components. Download it to further enhance your understanding of the fuel system and aid in your troubleshooting efforts. Good luck!