What Does A Jack Point Look Like

Alright, let's talk jack points. You might think, "it's just a place to lift the car," but understanding precisely where these are, and what they look like, is crucial for safe and effective vehicle maintenance. This isn't just about changing a tire; knowing your jack points is vital for more involved repairs, suspension work, or even just a thorough detailing session. Mess this up, and you're looking at potentially damaging your vehicle's frame, rocker panels, or even worse – causing it to slip and potentially injure yourself. This article will break down exactly what a jack point looks like, how to identify them, and how to use them safely. We'll also cover some common pitfalls and how to avoid them.

Purpose of a Jack Point Diagram

A jack point diagram, whether it's from your owner's manual or a dedicated service manual, is your roadmap to safely lifting your vehicle. Its purpose is threefold:

- Safety: The primary goal is to prevent accidents and injuries. Using the wrong lifting point can damage your vehicle and lead to catastrophic failure of the lifting process.

- Vehicle Integrity: Lifting the car at the designated points minimizes the risk of damaging sensitive areas like the fuel lines, brake lines, or the undercarriage.

- Efficiency: Knowing the correct points allows you to position your jack stands or other supports in the most effective locations for the task at hand.

Essentially, the diagram removes guesswork and ensures you're lifting your vehicle in a way that's both safe for you and safe for your car.

Key Specs and Main Parts (The Anatomy of a Jack Point)

Jack points aren't universal; they vary significantly depending on the vehicle's make, model, and even trim level. However, there are some common characteristics to look for. Here's a breakdown:

- Reinforced Area: Jack points are always located on reinforced sections of the vehicle's frame or chassis. This is because these areas are designed to withstand the concentrated weight of the vehicle during lifting.

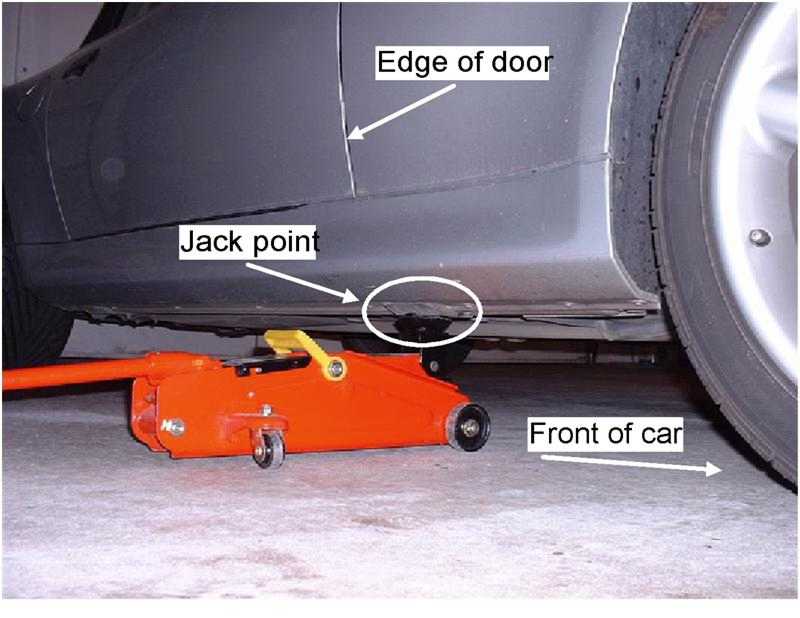

- Location: Typically, you'll find jack points along the rocker panels (the side panels beneath the doors) and near the front and rear suspension mounting points.

- Visible Indicators: Some manufacturers include visual cues to help you identify jack points. These may include:

- Notches or Slots: Specifically designed to accommodate the jack's lifting pad or arm.

- Reinforced Seams: Welded seams that indicate a reinforced area of the body.

- Textured Surface: A slightly rougher surface compared to the surrounding metal, often indicating a reinforced area.

- Arrows or Triangles: Molded into the plastic trim indicating the location.

- Pinch Welds: Common on many vehicles, the jack point is located on a section of pinch weld that is usually thicker and reinforced compared to the rest of the weld. Pinch welds are formed by joining multiple layers of sheet metal together.

- Frame Rails: For vehicles with a separate frame (like trucks and some older cars), the jack points will be located on the frame rails. These are usually easy to identify as they are robust steel beams running along the length of the vehicle.

Symbols and Diagram Conventions

Understanding the symbols used in a jack point diagram is critical for accurate interpretation. Here's a guide to common conventions:

- Solid Lines: Typically represent the outline of the vehicle's body or frame.

- Dashed Lines: May indicate hidden or underlying components.

- Circles or Squares: Often used to mark the exact location of a jack point.

- Arrows: Indicate the direction of force or the recommended placement of the jack.

- Colors: While not always present, different colors might highlight different types of jack points (e.g., one color for the pinch welds, another for the frame rails).

- Icons: Small icons representing a jack, jack stand, or other lifting equipment. These icons help visually guide you to the correct placement.

Pay close attention to any notes or legends accompanying the diagram. These often provide crucial context and specific instructions for your vehicle model. Also understand the diagrams are not always to scale, so finding the general area is key.

How It Works (Weight Distribution and Load Bearing)

The fundamental principle behind a jack point is load distribution. When you lift a vehicle, you're concentrating a significant amount of weight onto a small area. Jack points are engineered to handle this concentrated load without collapsing or deforming. The reinforced structure beneath the jack point spreads the force across a wider area, preventing damage to the surrounding body panels or frame. In essence, the design is such that the metal at the jack point can withstand the force exerted by the jack without bending or buckling.

Think of it like this: stepping on a thin piece of plywood will likely cause it to bend or break. But if you place a support beam beneath the plywood at the point where you're stepping, the beam distributes the weight and prevents the plywood from failing. That's essentially what a jack point does for your vehicle.

Real-World Use and Troubleshooting

Okay, you've got the diagram and know where the jack points should be. But what happens when things aren't so straightforward?

- Rust and Corrosion: Rust can compromise the structural integrity of jack points, making them unsafe to use. Inspect your jack points regularly for signs of rust. If rust is present, consult a professional to assess the damage and determine if the area can be safely used.

- Damaged Jack Points: Sometimes, previous improper jacking attempts can damage the jack points. Bent pinch welds, crushed rocker panels, or deformed frame rails are all signs of a compromised jack point. If you see any of these issues, DO NOT use the damaged area as a jack point. Find an alternative lifting location or consult a professional.

- Incorrect Jack Placement: Even with a diagram, it's possible to misplace the jack. Always double-check that the jack's lifting pad is centered on the jack point before applying any pressure.

- Diagram Discrepancies: In rare cases, the jack point diagram may not perfectly match your vehicle (due to production variations or aftermarket modifications). If you're unsure, consult a professional mechanic.

Basic Troubleshooting Tip: If you're struggling to locate a jack point, use a flashlight to get a better view. Also, try feeling around the area with your hand (wearing gloves, of course) to identify any reinforced sections or notches.

Safety: Risky Components and Precautions

Safety is paramount when working with jack points. These are critical areas that if compromised, will endanger the user. Here are some key safety considerations:

- Pinch Welds: While common jack points, pinch welds can be easily bent or crushed if the jack is not properly positioned or if the weld is weakened by rust. Always use a jack pad or adapter specifically designed for pinch welds.

- Rocker Panels: Rocker panels are relatively thin and can be easily damaged if you lift the vehicle in the wrong place. Never lift the vehicle directly on the rocker panel unless it's specifically designated as a jack point.

- Plastic Trim: Some vehicles have plastic trim covering the jack points. Ensure you remove or properly position the trim before lifting the vehicle. Lifting against plastic trim can damage it and potentially lead to the jack slipping.

- Hydraulic Jacks: Hydraulic jacks can fail, causing the vehicle to drop suddenly. Always use jack stands to support the vehicle before performing any work underneath it. Never rely solely on the jack to hold the vehicle up.

- Uneven Ground: Never attempt to jack up a vehicle on uneven or unstable ground. This can cause the jack to slip or tip over. Always work on a level, solid surface.

Remember, if you're ever unsure about the correct lifting procedure, consult a qualified mechanic. It's always better to be safe than sorry.

We've covered a lot of ground here, from understanding the purpose of jack points to identifying them on your vehicle and using them safely. This information should give you a solid foundation for performing basic maintenance and repairs. This article is for educational purposes, and this website is not liable for any injury or damage as a result of following this article. If you have further questions, consult a certified mechanic.

To help you further, we have a detailed jack point diagram template available for download. This template includes common symbols and conventions and can be used as a reference when inspecting your vehicle's lifting points.