What Does A Master Cylinder Hold

Understanding the brake system is crucial for any DIY mechanic or car enthusiast. A vital component within this system is the master cylinder. This article dives deep into the master cylinder, explaining its function, components, and how it contributes to safe and effective braking. Knowing the ins and outs of your master cylinder can empower you to perform basic diagnostics, maintenance, and even repairs, saving you money and ensuring your vehicle's safety.

Purpose and Importance

The master cylinder is the heart of your vehicle's hydraulic braking system. Its primary purpose is to convert the mechanical force from your brake pedal into hydraulic pressure, which is then transmitted to the wheel cylinders or calipers to engage the brakes. Without a properly functioning master cylinder, your brakes will be ineffective, making driving extremely dangerous. This understanding is vital for anyone undertaking brake system repairs, modifications, or even just wanting a deeper knowledge of their vehicle's mechanics.

Key Specs and Main Parts

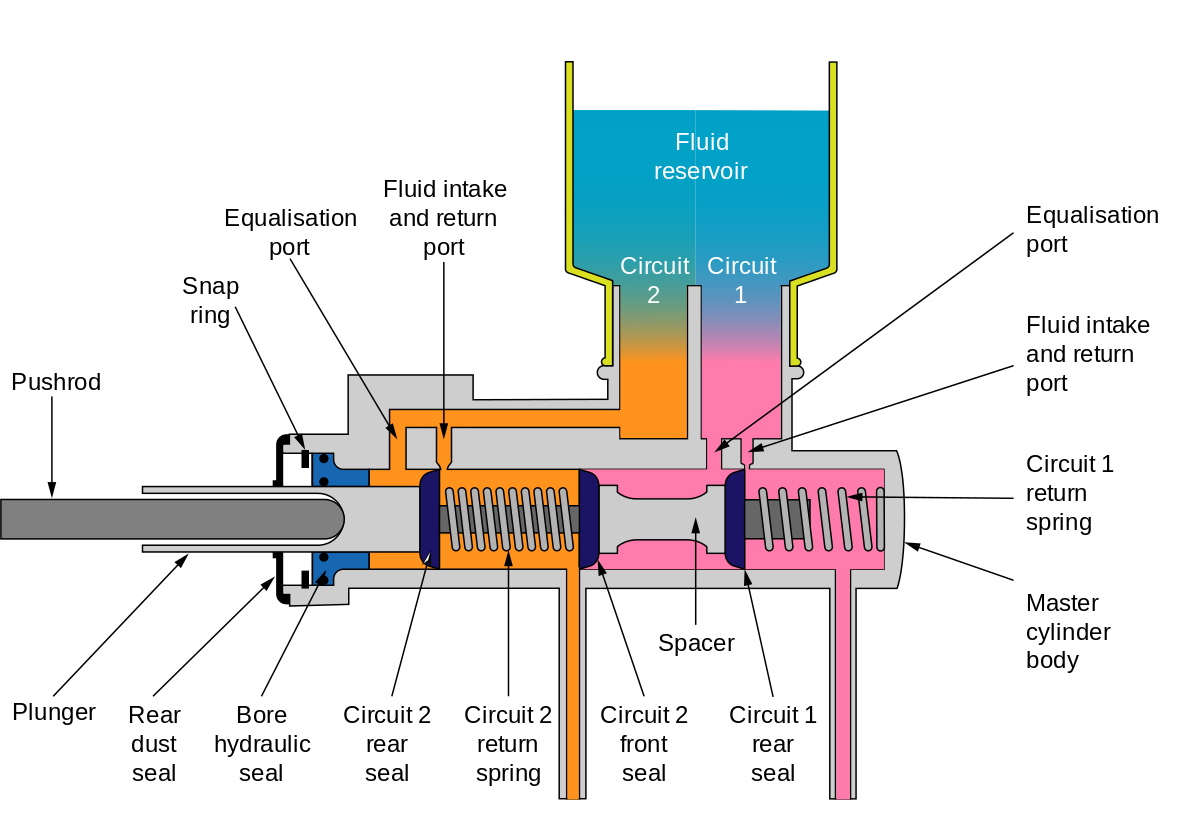

Let's break down the main components and key specifications of a typical master cylinder:

* Reservoir: This is a translucent plastic container that holds the brake fluid supply. It's crucial to maintain the correct fluid level in the reservoir. The reservoir usually has two chambers, one for the front brakes and one for the rear. This dual-chamber design provides a safety redundancy; if one circuit fails, the other can still provide braking force. * Cylinder Bore: This is the precision-machined internal diameter of the cylinder where the pistons move. The bore size is a critical specification, as it directly affects the amount of hydraulic pressure generated. A larger bore will produce lower pressure but higher fluid volume, while a smaller bore will produce higher pressure but lower fluid volume. * Pistons: Most modern vehicles utilize a dual master cylinder, meaning it contains two pistons operating in series. Each piston controls a separate brake circuit (usually front and rear). This dual design ensures that a failure in one circuit doesn't completely disable the entire braking system. * Seals (Cups): These are rubber or synthetic seals that prevent brake fluid from leaking past the pistons. They are critical for maintaining hydraulic pressure. Over time, these seals can degrade and leak, leading to brake failure. * Springs: Springs return the pistons to their resting position when the brake pedal is released. * Ports: These are openings in the master cylinder body that connect to the brake lines leading to the wheels. They allow brake fluid to flow out to the calipers/wheel cylinders and back into the master cylinder. * Residual Pressure Valve (RPV): Found in some older master cylinders, this valve maintains a slight amount of pressure in the brake lines (typically 8-12 psi) to help keep the brake shoes in close proximity to the drums. RPVs are less common in modern systems.How It Works

The operation of the master cylinder is relatively straightforward. When you press the brake pedal, the pushrod connected to the pedal pushes the primary piston inside the master cylinder. This movement pressurizes the brake fluid in the primary circuit. As the primary piston moves, it also pushes the secondary piston, pressurizing the brake fluid in the secondary circuit.

The pressurized brake fluid then travels through the brake lines to the calipers (in disc brake systems) or wheel cylinders (in drum brake systems). The pressure forces the caliper pistons to clamp the brake pads against the rotors, or the wheel cylinder pistons to push the brake shoes against the drums, slowing the vehicle.

When you release the brake pedal, the springs inside the master cylinder push the pistons back to their resting positions. This releases the pressure in the brake lines, allowing the calipers or wheel cylinders to retract, disengaging the brakes.

Real-World Use - Basic Troubleshooting

Here are a few common issues and basic troubleshooting steps you can perform:

* Spongy Brake Pedal: This is often caused by air in the brake lines. Bleeding the brakes is usually the solution. However, a spongy pedal can also indicate a failing master cylinder, especially if bleeding doesn't resolve the issue. * Brake Fluid Leaks: Check for leaks around the master cylinder, brake lines, and calipers/wheel cylinders. Leaks can lead to a loss of brake pressure and are a serious safety concern. A leak around the master cylinder itself often indicates failing seals within the cylinder. * Brake Pedal Slowly Sinking to the Floor: This can be a sign of a failing master cylinder. The internal seals may be leaking, allowing fluid to bypass the pistons, resulting in a gradual loss of pressure. * Low Brake Fluid Level: Consistently low brake fluid levels indicate a leak in the system. Find and repair the leak immediately. * Contaminated Brake Fluid: Brake fluid is hygroscopic, meaning it absorbs moisture from the air. Over time, this moisture can corrode internal brake components and reduce the fluid's boiling point, leading to brake fade. Brake fluid should be flushed and replaced every two years, or as recommended by your vehicle manufacturer.Safety – Risky Components

Working with the braking system involves inherent risks, particularly when dealing with hydraulic components. Brake fluid is corrosive and can damage paint and other surfaces. Always wear eye protection and gloves when working with brake fluid.

The most significant risk involves the master cylinder itself. If the master cylinder fails, your brakes will be severely compromised. Therefore, it is crucial to properly diagnose and repair any issues with the master cylinder promptly.

Be extremely cautious when bleeding brakes. Follow proper procedures to avoid introducing air into the system or damaging brake components.

After any brake work, always test the brakes thoroughly in a safe environment before driving on public roads. This includes checking for proper pedal feel, stopping power, and any unusual noises or vibrations.

Finally, remember that brake systems are critical safety components. If you are unsure about any aspect of brake repair, it is best to consult a qualified mechanic.