What Does A V8 Engine Mean

Alright, let's dive deep into the heart of many powerful vehicles: the V8 engine. This article is for you, the experienced DIYer, the modifier, the weekend mechanic, who wants to truly understand what makes a V8 tick. Understanding this engine architecture is crucial for everything from routine maintenance to performance upgrades and even diagnosing those frustrating mechanical gremlins. Consider this your comprehensive guide.

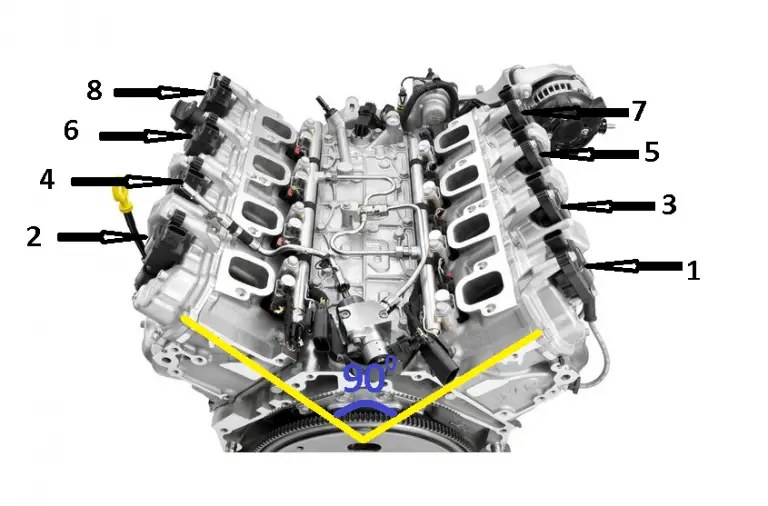

Purpose and Diagram Significance

Why should you care about a detailed explanation of a V8? Because knowledge is power! Specifically, this understanding helps in several crucial areas:

- Diagnostics & Troubleshooting: Knowing the components and their interactions allows you to pinpoint issues faster.

- Repair & Maintenance: You'll be able to approach tasks like head gasket replacements or timing chain adjustments with more confidence.

- Performance Tuning: Understanding the engine's internals is essential for optimizing performance through modifications like camshaft upgrades or forced induction.

- Modifications: Planning major changes requires a thorough grasp of how everything works together, avoiding costly mistakes.

Think of the diagram as your roadmap. It visually lays out the components and their relationship, providing a quick reference during any engine-related task. (We have a detailed V8 engine diagram ready for download, which you can use as a companion to this article.)

Key Specs and Main Parts

The defining characteristic of a V8 engine is its configuration: eight cylinders arranged in two banks of four, forming a "V" shape. This configuration provides a good balance of power, smoothness, and relatively compact size (compared to, say, an inline-8). Let's break down the key components:

Main Components:

- Engine Block: The foundation of the engine, housing the cylinders, coolant passages, and oil passages. The V-angle, typically 90 degrees but sometimes 60 degrees, is a critical design parameter.

- Cylinders: These are the chambers where combustion occurs. The bore (diameter of the cylinder) and stroke (distance the piston travels) are key measurements that determine displacement (engine size).

- Pistons: These move up and down within the cylinders, driven by the combustion process. They are connected to the connecting rods via wrist pins.

- Connecting Rods: These connect the pistons to the crankshaft, converting the reciprocating motion of the pistons into rotary motion.

- Crankshaft: The rotating shaft that converts the linear motion of the pistons into rotational power. It's supported by main bearings and is responsible for driving accessories like the alternator and water pump.

- Cylinder Heads: These sit atop the engine block and contain the intake and exhaust valves, spark plugs (in a gasoline engine), and combustion chambers.

- Valves: Control the flow of intake air and exhaust gases into and out of the cylinders. They are actuated by the camshaft.

- Camshaft: A rotating shaft with lobes that open and close the valves. The camshaft profile (shape of the lobes) determines the valve timing and lift, which significantly affects engine performance.

- Intake Manifold: Distributes air (and fuel in older systems) to the cylinders.

- Exhaust Manifold (or Headers): Collects exhaust gases from the cylinders and directs them to the exhaust system.

- Oil Pan: Reservoir for engine oil.

- Water Pump: Circulates coolant to regulate engine temperature.

Key Specs:

- Displacement: The total volume of all the cylinders (usually expressed in liters or cubic inches).

- Compression Ratio: The ratio of the cylinder volume at its largest (piston at bottom dead center) to its smallest (piston at top dead center). Higher compression ratios generally lead to more power but require higher octane fuel.

- Firing Order: The sequence in which the cylinders fire. A well-chosen firing order helps to minimize vibration and distribute load evenly.

How It Works

The V8 engine operates on the four-stroke principle: Intake, Compression, Combustion (Power), and Exhaust.

- Intake: The piston moves down, creating a vacuum in the cylinder. The intake valve opens, and a mixture of air and fuel (or just air in direct injection engines) is drawn into the cylinder.

- Compression: The intake valve closes, and the piston moves up, compressing the air-fuel mixture. This increases the temperature and pressure, making combustion more efficient.

- Combustion (Power): The spark plug ignites the compressed air-fuel mixture, creating a rapid expansion of gases. This forces the piston down, generating power.

- Exhaust: The exhaust valve opens, and the piston moves up, pushing the exhaust gases out of the cylinder.

This cycle repeats continuously in each cylinder, with the cylinders firing in a specific sequence (firing order) to deliver a smooth and powerful output.

Symbols - Reading The Diagram

While the exact symbols will vary slightly depending on the specific diagram, here are some common conventions:

- Solid Lines: Typically represent mechanical connections, such as connecting rods or the crankshaft.

- Dashed Lines: Often indicate fluid lines, like coolant hoses or oil passages.

- Colors: Can be used to differentiate between systems. For example, blue might represent coolant, red might represent oil, and yellow might represent fuel.

- Arrows: Show the direction of fluid flow (coolant, oil, fuel).

- Specific Icons: Icons are used to represent specific parts, such as a stylized image of a piston, valve, or spark plug.

Real-World Use - Basic Troubleshooting Tips

Understanding the V8 architecture allows you to make informed diagnoses. Here are a few common issues and how your knowledge can help:

- Misfires: A misfire (when a cylinder doesn't fire properly) can be caused by a faulty spark plug, ignition coil, fuel injector, or even a valve problem. Knowing the firing order and understanding the ignition and fuel systems helps you narrow down the culprit.

- Low Compression: Low compression in one or more cylinders could indicate worn piston rings, leaking valves, or a blown head gasket. A compression test is crucial for diagnosing this.

- Oil Leaks: Knowing where oil passages are located helps you pinpoint the source of a leak. Common leak areas include valve covers, the oil pan, and crankshaft seals.

- Overheating: Overheating can be caused by a faulty water pump, thermostat, radiator, or a blockage in the coolant system. Understanding the coolant flow path is essential for troubleshooting.

Important: Always consult a repair manual specific to your vehicle for detailed troubleshooting procedures and torque specifications.

Safety - Risky Components

Working on any engine involves risks. Be especially cautious around these components:

- High-Pressure Fuel System: Fuel injection systems operate at high pressures. Always relieve the pressure before disconnecting fuel lines.

- Electrical System: The ignition system generates high voltages. Disconnect the battery before working on any electrical components.

- Rotating Parts: Never work on an engine while it's running unless absolutely necessary (and even then, exercise extreme caution). Keep hands and clothing away from moving parts.

- Hot Surfaces: Exhaust manifolds and other engine components get extremely hot. Allow the engine to cool completely before working on it.

Always wear appropriate safety gear, including eye protection and gloves.

By understanding the architecture, components, and operation of the V8 engine, you're well-equipped to tackle a wide range of maintenance and modification tasks. Remember to always consult a repair manual specific to your vehicle and prioritize safety. We encourage you to download the detailed V8 engine diagram we have available; it will serve as a valuable reference in your future endeavors. Happy wrenching!