What Does All Wheel Drive Do

Alright, let's dive into the world of All-Wheel Drive (AWD) systems. This is a system that a lot of people understand the general idea of, but the nitty-gritty details can be a bit of a mystery. This article is designed to give you, the experienced DIYer, a solid understanding of AWD – enough to diagnose issues, potentially tackle some repairs, and generally be more informed about your vehicle's drivetrain.

Understanding All-Wheel Drive: Purpose and Components

The purpose of understanding the AWD system intimately is multifaceted. For starters, when a problem arises, you’ll be able to accurately describe the symptoms to a mechanic, potentially saving yourself diagnostic fees. Secondly, you'll be better equipped to troubleshoot minor issues yourself. And finally, understanding the system can help you make informed decisions about vehicle modifications or upgrades.

Key Specs and Main Parts

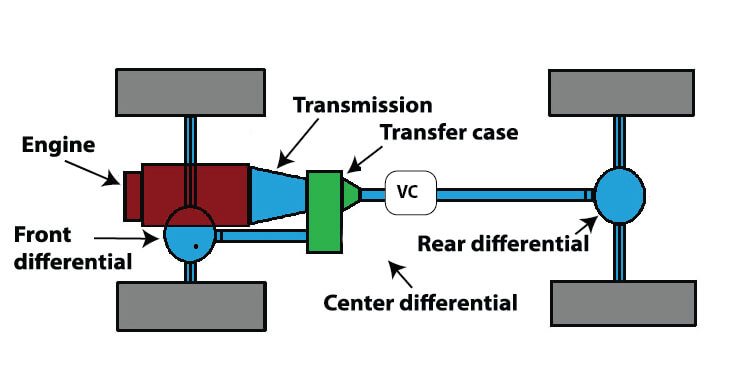

The core purpose of an AWD system is to distribute torque from the engine to all four wheels. This maximizes traction, especially in slippery conditions like snow, ice, or mud. There are two main types of AWD systems:

- Part-Time AWD: This system typically operates in two-wheel drive (2WD) and engages all four wheels only when the driver manually selects AWD. It uses a transfer case to lock the front and rear axles together. This type of AWD is generally found on older vehicles or those designed for serious off-roading.

- Full-Time AWD: Also sometimes referred to as "automatic AWD," this system constantly distributes torque to all four wheels. It uses a center differential (or viscous coupling, or electronic clutch pack) to allow for speed differences between the front and rear axles, which is crucial for on-road driving.

Here are the main components you'll typically find in an AWD system:

- Engine: The power source, naturally.

- Transmission: Transfers power from the engine to the drivetrain.

- Transfer Case (Part-Time AWD): Splits torque between the front and rear axles, and may have low-range gearing for off-roading.

- Center Differential (Full-Time AWD): Allows for speed differences between the front and rear axles. Common types include open differentials, viscous couplings, Torsen differentials, and electronic clutch packs.

- Front Differential: Distributes torque between the front wheels.

- Rear Differential: Distributes torque between the rear wheels.

- Drive Shafts (Propeller Shafts): Connect the transmission/transfer case to the front and rear differentials.

- Axle Shafts: Connect the differentials to the wheels.

- Wheel Speed Sensors: Detect wheel speed, crucial for traction control and stability control systems that often work in conjunction with AWD.

- Electronic Control Unit (ECU): Manages the AWD system, often based on input from various sensors.

Understanding Common Symbols

When reading diagrams of AWD systems, you'll encounter various symbols. Here's a breakdown of some common ones:

- Solid Lines: Typically represent mechanical connections, like drive shafts or axles. Thicker lines might indicate main power flow.

- Dashed Lines: Usually represent control lines, such as electrical wiring or vacuum lines.

- Arrows: Indicate the direction of power flow or rotation.

- Gear Icons: Represent gears within the transmission, transfer case, or differentials.

- Differential Symbols: Vary depending on the type of differential, but often involve a circle with lines connecting the input and output shafts. A limited-slip differential (LSD) symbol might include additional markings indicating its locking mechanism.

- Sensor Symbols: Typically represent sensors like wheel speed sensors, throttle position sensors, or yaw rate sensors. They often look like small boxes with wires coming out.

- ECU Symbol: Usually represented by a rectangle, often with the acronym "ECU" or "TCU" (Transmission Control Unit) inside.

- Colors: May vary depending on the diagram, but often used to differentiate between different components or systems. For example, the hydraulic system might be rendered in blue.

How AWD Works

Let's break down how the different types of AWD systems function.

Part-Time AWD: The engine's power goes through the transmission to the transfer case. When AWD is engaged, the transfer case locks the front and rear drive shafts together, forcing them to rotate at the same speed. This provides maximum traction but should only be used on slippery surfaces. Driving with part-time AWD engaged on dry pavement can cause driveline binding, which can damage the transfer case and other components.

Full-Time AWD: In a full-time AWD system, the engine's power is directed through the transmission to the center differential. The center differential splits the torque between the front and rear axles. The key difference between full-time and part-time AWD is the ability to handle speed differences between the front and rear axles. Here's how different types of center differentials achieve this:

- Open Differential: Allows for the greatest speed difference between the axles but can suffer from wheel spin. If one axle loses traction, it will receive all the power, while the other axle receives none.

- Viscous Coupling: Contains a fluid that becomes more viscous (thicker) when there's a speed difference between the input and output shafts. This increased viscosity transfers torque to the axle with more traction.

- Torsen Differential: A torque-sensing differential that mechanically transfers torque to the axle with more grip. It's more effective than a viscous coupling but can still struggle in extreme low-traction situations.

- Electronic Clutch Pack: Uses an electronically controlled clutch to vary the amount of torque transferred between the front and rear axles. This allows for precise control and can be integrated with traction control and stability control systems.

Real-World Use and Basic Troubleshooting

Here are some common problems and basic troubleshooting tips for AWD systems:

- Driveline Binding (Part-Time AWD): If you experience a shuddering or binding sensation when turning on dry pavement with part-time AWD engaged, you're likely experiencing driveline binding. Disengage AWD immediately to avoid damage.

- Excessive Tire Wear: Uneven tire wear can indicate problems with the AWD system, such as a malfunctioning center differential or misaligned axles.

- Unusual Noises: Grinding, whining, or clunking noises from the drivetrain can indicate worn bearings, gears, or other components.

- AWD Warning Light: If the AWD warning light illuminates on the dashboard, it indicates a problem with the AWD system. This could be due to a faulty sensor, a malfunctioning actuator, or a problem with the ECU. A scan tool will be needed to diagnose the cause.

- Wheel Spin in Low-Traction Situations: If you experience excessive wheel spin in low-traction conditions, it could indicate a problem with the differentials or the traction control system.

Troubleshooting Tips: Start by visually inspecting the components for leaks, damage, or wear. Check the fluid levels in the transfer case and differentials. If you have access to a scan tool, check for any fault codes related to the AWD system.

Safety Considerations

Working on AWD systems involves several safety risks. Here are some key points to keep in mind:

- High Torque: Drivetrain components are subjected to high torque. Use proper tools and techniques to avoid injury.

- Rotating Parts: Be extremely careful when working around rotating parts, such as drive shafts and axles. Never work under a vehicle supported only by a jack. Use jack stands.

- Fluid Hazards: Gear oil and other fluids used in AWD systems can be harmful. Wear gloves and eye protection.

- Springs & Pressurized Systems: Some AWD systems incorporate hydraulic components. Relieve pressure before disconnecting any lines.

- Electrical Components: Disconnect the battery before working on any electrical components of the AWD system.

Specifically, the drive shaft is a potentially dangerous component due to its high rotational speed and the forces it can exert. Ensure the vehicle is properly supported and the drivetrain is locked (parking brake engaged) before working near it.

This information provides a solid foundation for understanding AWD systems. Remember, safety is paramount. When in doubt, consult a qualified mechanic.

We have a detailed diagram of a typical AWD system available for download. This diagram provides a visual representation of the components and their relationships, which can be helpful for understanding how the system works and for troubleshooting issues. Contact us and reference "AWD Diagram Request" and we will gladly forward it to you.