What Does All Wheel Drive Means

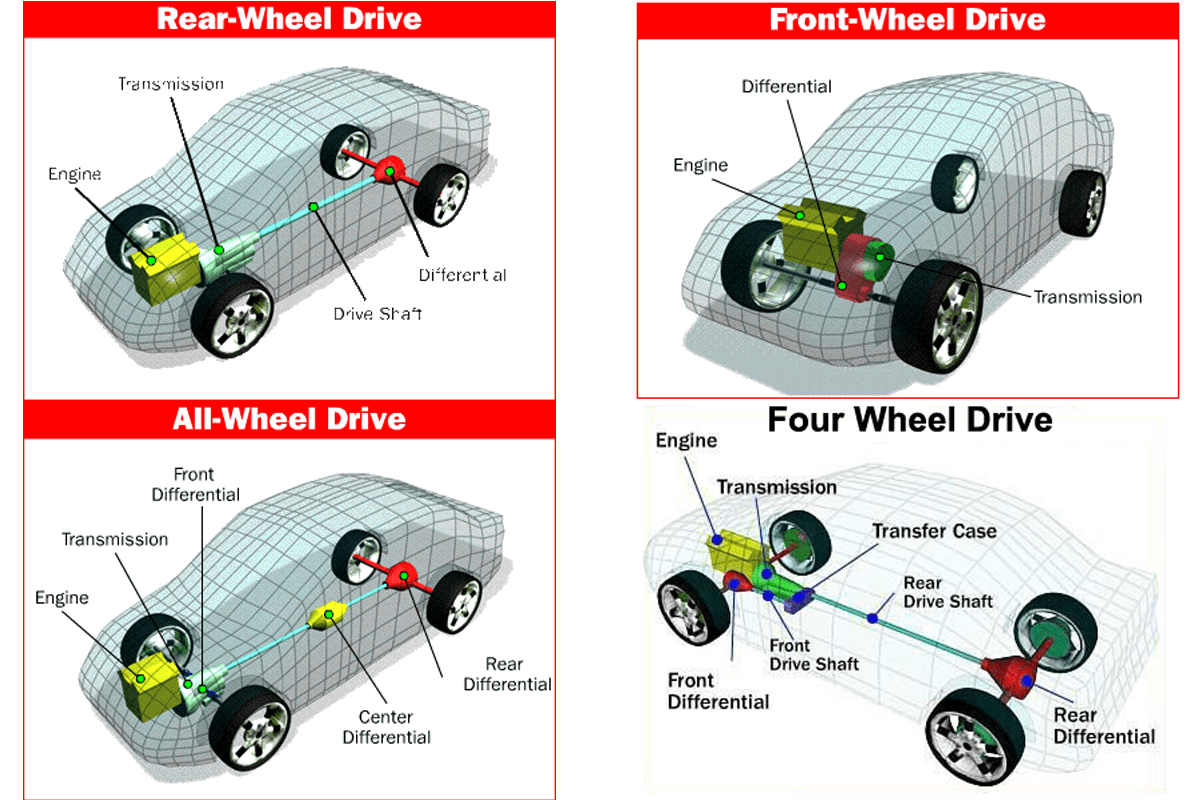

Alright, let's dive into the fascinating world of All-Wheel Drive (AWD) systems. If you're a seasoned DIYer or modder, understanding AWD is crucial. This isn't just about bragging rights; it's about diagnosing issues, planning upgrades, and appreciating the engineering marvel that keeps your vehicle planted on the road in challenging conditions. Consider this article your go-to resource for demystifying AWD, and remember, we have a detailed diagram available for download to further illustrate these concepts.

Purpose of Understanding AWD

Why bother learning about AWD? Several reasons spring to mind:

- Troubleshooting & Repair: When things go wrong, understanding how the system *should* work is half the battle. You can identify problematic components and potentially save yourself a trip to the mechanic.

- Performance Upgrades: Thinking about boosting your car's power? Knowing how your AWD system handles that power is vital. You might need to upgrade components to avoid premature failure.

- DIY Maintenance: Certain AWD systems require specific maintenance procedures, like fluid changes for differentials and transfer cases. Understanding the system empowers you to handle these tasks yourself.

- Informed Decisions: When buying a new or used AWD vehicle, you can ask informed questions and understand the system's capabilities and limitations.

Key Specs and Main Parts

At its core, AWD aims to deliver power to all wheels, providing improved traction and control, especially in slippery conditions. But there's no single "AWD" system; they vary significantly. Here are the key components you'll find in most AWD setups:

- Engine: The source of power. Generally, the more power the better for off road capability or to power through snow

- Transmission: Transfers engine power to the drivetrain. It also contains gears that provide various speed/torque ratios.

- Transfer Case (or Power Transfer Unit - PTU): This is a crucial component. It splits power from the transmission and sends it to both the front and rear axles. Think of it as the central hub for AWD. PTUs, in some modern vehicles with transverse mounted engines, are usually lighter duty and may be more prone to overheating.

- Front Differential: Allows the front wheels to rotate at different speeds during turns. Essential for smooth cornering.

- Rear Differential: Same as the front, but for the rear wheels.

- Driveshaft(s): Connects the transfer case to the front and rear differentials. In some front biased systems the driveshaft to the rear differential may be smaller.

- Axle Shafts: Transfer power from the differentials to the individual wheels.

- Wheel Speed Sensors: (Often part of the ABS system) Detect wheel slippage and can trigger AWD activation in some systems.

- Coupling (Viscous, Clutch-Based, or Electronic): Controls the amount of torque sent to the rear wheels (or front in some less common setups). This is the 'brain' of many modern AWD systems, determining when and how much power to distribute.

Symbols & Diagram Interpretation

When looking at a technical diagram of an AWD system, pay attention to these common symbols:

- Solid Lines: Represent mechanical connections, like shafts and gears. The thicker the line, the more robust the component.

- Dashed Lines: Often indicate hydraulic or electrical connections, like control signals for the coupling or fluid lines for hydraulic actuators.

- Arrows: Show the direction of power flow. Very important for understanding how torque is distributed.

- Color Coding: Different manufacturers may use different color schemes, but often, colors represent specific subsystems, like lubrication systems or electronic control circuits. Always refer to the legend accompanying the diagram.

- Icons: Represent specific components, such as gears (usually depicted as interlocking circles), differentials (often symbolized by a series of gears and shafts), and couplings (represented by clutches or viscous units).

How It Works: An Overview

AWD systems aren't all created equal. Here's a breakdown of the most common types:

- Full-Time AWD: Continuously sends power to all four wheels. Typically uses a center differential or viscous coupling to allow for differing wheel speeds. Provides consistent traction but can slightly reduce fuel economy. Land Rover's Terrain Response system is an example.

- Part-Time AWD: Designed to be engaged only when needed (e.g., in snow or off-road). Typically locks the front and rear axles together, providing maximum traction but should never be used on dry pavement due to driveline binding. Found mostly on older trucks and SUVs.

- Automatic AWD (On-Demand): The most common type in modern cars. Normally operates in front-wheel drive (FWD) or rear-wheel drive (RWD) and engages the other axle when slippage is detected. Uses sensors (like wheel speed sensors) and a coupling (viscous, clutch-based, or electronic) to distribute torque. Often more fuel-efficient than full-time systems. A common version is a front wheel drive car that sends power to the rear when the front wheels slip.

The coupling is key. Viscous couplings use a fluid that thickens when sheared (when there's a difference in wheel speed), transferring torque. Clutch-based systems use electronically controlled clutches to engage and disengage power transfer. Electronic couplings offer the most sophisticated control, allowing for variable torque distribution based on factors like steering angle, throttle position, and yaw rate.

Real-World Use and Troubleshooting

Here are some basic troubleshooting tips:

- Unusual Noises: Grinding, clunking, or whining sounds, especially during turns, can indicate problems with the differentials, transfer case, or axle shafts. Pay close attention to when the noise occurs (e.g., only when AWD is engaged).

- Vibrations: Can be caused by worn CV joints (on axle shafts) or an unbalanced driveshaft.

- Warning Lights: Many modern vehicles have AWD warning lights that illuminate when a problem is detected. Get the code read to pinpoint the issue.

- AWD System Not Engaging: Check fuses and relays. If those are good, the problem could be a faulty coupling, sensor, or control module.

- Fluid Leaks: Inspect the transfer case and differentials for leaks. Low fluid levels can cause significant damage.

Safety Considerations

Working on AWD systems can be risky. Here are some safety tips:

- Proper Lifting: Always use jack stands when working under the vehicle. Ensure the vehicle is securely supported.

- Driveline Binding: Never operate a part-time AWD system on dry pavement. This can cause severe damage to the drivetrain.

- Torque Specifications: Always use a torque wrench and follow the manufacturer's torque specifications when reassembling components. Over-tightening can damage parts.

- High-Pressure Fluids: Be cautious when working with hydraulic AWD systems. High-pressure fluid can cause serious injury.

- Electrical Components: Disconnect the battery before working on any electrical components to avoid short circuits.

- Rotating Parts: Keep hands and clothing away from rotating parts when the engine is running. The driveshaft is a particularly dangerous rotating component.

AWD systems are complex and precise. If you're unsure about any aspect of the repair, it's always best to consult a qualified mechanic. Remember, we have a detailed AWD system diagram available for download. This diagram will provide a visual aid to help you better understand the components and their relationships. Good luck, and stay safe!