What Does An Electric Motor Do

Alright, let's dive deep into the heart of electric motors. Whether you're considering an EV conversion, troubleshooting a failing accessory motor, or just plain curious, understanding how these things work is crucial. This article will break down the electric motor, its components, and how they all come together to generate motion. We'll be focusing on the types of motors commonly found in automotive applications, primarily brushed and brushless DC motors.

Why Bother Learning This?

Knowing the inner workings of an electric motor empowers you. It allows for:

- More informed repairs: Instead of blindly replacing parts, you can diagnose issues more accurately.

- Customization: Want to modify a motor for increased performance? Understanding the basics is essential.

- EV Conversions: The electric motor is, obviously, the core component. Knowing its limitations and capabilities is paramount.

- General Understanding: Even if you're not actively working on motors, knowing how they work adds another tool to your DIY toolbox.

Key Specs and Main Parts

Before we jump into operation, let’s familiarize ourselves with the major players:

Key Specifications

- Voltage (V): The electrical potential difference applied to the motor. Higher voltage often equates to higher speed, but also higher risk.

- Current (A): The amount of electrical charge flowing through the motor. Directly related to torque (turning force).

- Power (W): The rate at which the motor does work (Voltage x Current).

- Torque (Nm or lb-ft): The twisting force the motor can exert. This is what actually turns the wheels.

- Speed (RPM): Revolutions per minute. How fast the motor shaft spins.

- Efficiency (%): The ratio of mechanical power output to electrical power input. No motor is 100% efficient.

Main Parts

- Stator: The stationary part of the motor. This typically houses the field windings or permanent magnets.

- Rotor (Armature): The rotating part of the motor. Contains windings that interact with the magnetic field of the stator to produce torque.

- Commutator (Brushed Motors): A segmented ring that reverses the current flow in the rotor windings at specific points in the rotation, maintaining torque.

- Brushes (Brushed Motors): Conductive blocks (usually carbon) that make contact with the commutator, supplying current to the rotor windings.

- Windings (Coils): Coils of wire that, when energized, create magnetic fields. Their configuration and number affect motor characteristics.

- Magnets (Permanent or Electromagnets): Create a magnetic field that interacts with the rotor windings to generate torque. Can be permanent (like in many small DC motors) or electromagnets (created by passing current through windings).

- Shaft: The rotating output of the motor that transmits the torque to the load (wheels, pump, etc.).

- Bearings: Reduce friction and support the rotor shaft.

- Housing: The outer casing that protects the motor components.

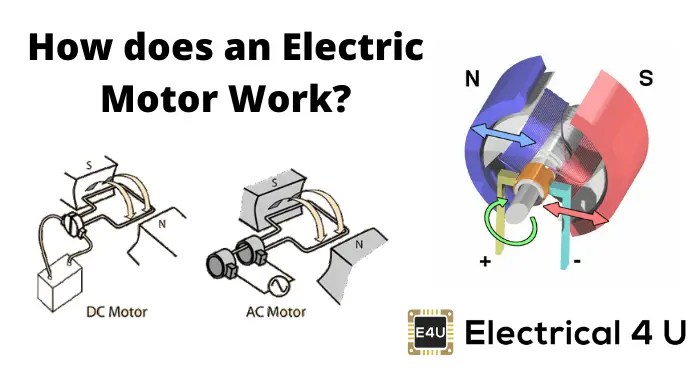

Understanding Motor Symbols

Diagrams are often used to represent electric motors in schematics. Here's a breakdown of common symbols:

- Circle with an "M" inside: The general symbol for an electric motor.

- Lines: Represent electrical conductors (wires).

- Coils: Depicted as loops or spirals, representing the windings. May have polarity markings (+/-).

- Brushes: Shown as small rectangles touching the commutator.

- Ground Symbol: Indicates a connection to the electrical ground (chassis) for safety.

Colors in wiring diagrams are also important. While the specifics can vary by manufacturer, common conventions include:

- Red: Typically used for positive (+) power.

- Black: Typically used for negative (-) or ground.

- Other colors: Used for control signals, sensor readings, or connections to other components. Always refer to the specific wiring diagram for the vehicle or component you're working on.

How It Works: The Electromagnetism Magic

The fundamental principle behind electric motor operation is electromagnetism. A current-carrying conductor (a wire) placed within a magnetic field experiences a force. This force is what makes the motor rotate.

Brushed DC Motor:

- Current flows through the brushes and commutator into the rotor windings.

- This current creates a magnetic field around the rotor windings.

- This magnetic field interacts with the magnetic field created by the stator magnets (either permanent magnets or electromagnetic windings).

- This interaction creates a force that causes the rotor to rotate.

- As the rotor rotates, the commutator segments switch the current flow in the rotor windings, ensuring that the magnetic field is always oriented in a way that maximizes torque. This is the key to continuous rotation.

Brushless DC (BLDC) Motor:

- BLDC motors have permanent magnets on the rotor and windings on the stator.

- Instead of brushes and a commutator, an electronic controller (ESC - Electronic Speed Controller) energizes the stator windings in a specific sequence.

- The ESC uses sensors (Hall effect sensors) to determine the rotor's position.

- Based on the rotor's position, the ESC energizes the appropriate stator windings, creating a rotating magnetic field that pulls the rotor along.

- This precise control allows for higher efficiency, longer lifespan (no brush wear), and better performance than brushed motors.

Real-World Use: Basic Troubleshooting

Here are some basic troubleshooting steps you can take when dealing with a faulty electric motor:

- Motor doesn't run at all:

- Check the power supply. Is the voltage correct?

- Inspect wiring for loose connections or breaks.

- Check fuses or circuit breakers.

- (Brushed Motors) Inspect the brushes for wear or damage. If they're worn down, replace them.

- (Brushed Motors) Check the commutator for dirt or corrosion. Clean it with a commutator stone or fine sandpaper.

- Motor runs slowly or weakly:

- Check for excessive load on the motor. Is something binding?

- Check the voltage. Is it dropping under load?

- (Brushed Motors) Inspect the brushes and commutator for wear and tear.

- Check the motor windings for shorts or open circuits (requires a multimeter).

- Motor makes unusual noises:

- Check for loose components or debris inside the motor.

- Inspect the bearings for wear or damage.

Safety First!

Electric motors can be dangerous if not handled properly. Here are some crucial safety precautions:

- Disconnect the power source before working on any electrical components.

- Use insulated tools to prevent electric shock.

- Be aware of high voltages. Capacitors can store a charge even after the power is disconnected. Discharge them safely before working on the circuit.

- Avoid working on electrical systems in wet or damp conditions.

- Never modify or tamper with safety devices.