What Does An Engine Filter Do

Alright, let's dive into engine filters. If you're wrenching on your own vehicles or even just thinking about some mods, understanding how these unsung heroes work is critical. We're talking about extending engine life, maintaining performance, and saving yourself some serious headaches down the road. Think of this as a deep dive, not just a surface skim.

Purpose of Engine Filters

The main purpose of engine filters - and we're generally talking about oil filters, air filters, and fuel filters here - is to protect the engine from contaminants. Without them, abrasive particles, dirt, and other debris would circulate throughout the engine, causing premature wear and tear on critical components. This, in turn, leads to reduced performance, increased fuel consumption, and, ultimately, engine failure. Imagine running sandpaper through your engine's moving parts; that's essentially what unfiltered contaminants are doing.

Understanding these filters is essential for:

- Preventative Maintenance: Knowing when and how to replace filters.

- Troubleshooting: Identifying filter-related performance issues.

- Modification Planning: Ensuring aftermarket parts are compatible with your engine's filtration needs.

- Repair and Overhaul: Understanding the role of filtration in engine health.

Key Specs and Main Parts

Let's break down each filter type individually:

Oil Filter

The oil filter removes contaminants from the engine oil, preventing them from circulating and damaging engine components. Key specs include:

- Micron Rating: Measures the size of particles the filter can trap. A lower micron rating means finer filtration. Common ratings range from 10-40 microns.

- Flow Rate: Indicates how much oil the filter can process per unit of time (e.g., gallons per minute - GPM).

- Burst Strength: The pressure the filter can withstand before failing.

- Filter Media: The material used to trap contaminants. Common materials include cellulose, synthetic fibers, and blended media.

- Canister: The outer shell that houses the filter media.

- Base Plate: The plate that attaches the filter to the engine. It typically has threaded holes for installation and oil inlet/outlet ports.

- Anti-Drainback Valve: Prevents oil from draining back into the engine when it's turned off, ensuring immediate lubrication upon startup.

- Bypass Valve: Allows oil to bypass the filter if it becomes clogged, preventing oil starvation to the engine.

Air Filter

The air filter prevents dirt, dust, and debris from entering the engine's combustion chamber. A clean air filter is crucial for optimal engine performance and fuel efficiency. Key specs include:

- Filtration Efficiency: The percentage of particles the filter can trap.

- Airflow Restriction: The resistance the filter offers to airflow. Lower restriction is generally better for performance, but it can compromise filtration efficiency.

- Filter Media: Common materials include paper, cotton gauze, and foam.

- Pleated Design: Increases the surface area of the filter media, improving filtration capacity.

- Frame: Provides structural support for the filter media.

Fuel Filter

The fuel filter removes contaminants from the fuel before it reaches the engine's fuel injectors or carburetor. This protects these sensitive components from damage and ensures optimal fuel delivery. Key specs include:

- Micron Rating: Similar to oil filters, this indicates the size of particles the filter can trap.

- Flow Rate: The amount of fuel the filter can process per unit of time.

- Filter Media: Common materials include paper, synthetic fibers, and stainless steel mesh.

- Housing: The enclosure that houses the filter media. It can be made of metal or plastic.

How It Works

Let's look at how each filter does its job:

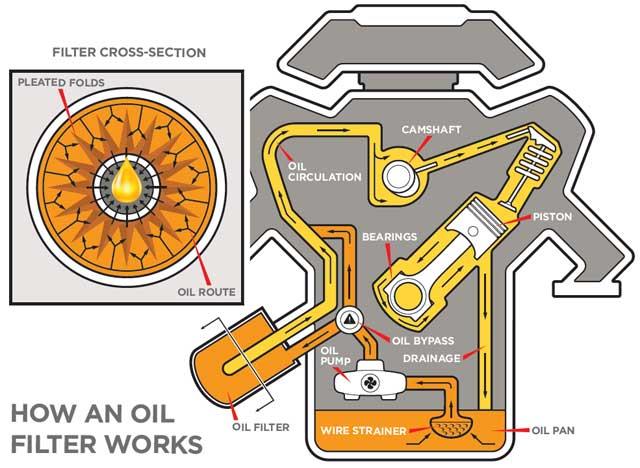

Oil Filter:

- Oil is pumped from the engine's oil pump.

- Oil enters the filter housing through the inlet ports in the base plate.

- The oil passes through the filter media, where contaminants are trapped.

- Clean oil exits the filter through the outlet port and returns to the engine to lubricate its components.

- If the filter becomes clogged, the bypass valve opens, allowing unfiltered oil to bypass the filter and continue lubricating the engine. This is a safeguard, but it means unfiltered oil is circulating.

Air Filter:

- Air is drawn into the engine through the air intake system.

- The air passes through the air filter, where dirt, dust, and debris are trapped by the filter media.

- Clean air enters the engine's combustion chamber, where it mixes with fuel and is ignited.

Fuel Filter:

- Fuel is pumped from the fuel tank.

- The fuel enters the fuel filter housing.

- The fuel passes through the filter media, where contaminants are trapped.

- Clean fuel exits the filter and is delivered to the engine's fuel injectors or carburetor.

Real-World Use – Basic Troubleshooting Tips

Here are some common issues and how to diagnose them:

- Oil Filter: Low oil pressure, knocking noises, or rapid oil darkening can indicate a clogged or failing oil filter. Check the oil pressure gauge and inspect the oil for contaminants.

- Air Filter: Reduced engine power, poor fuel economy, and a check engine light can indicate a clogged air filter. Visually inspect the filter for dirt and debris.

- Fuel Filter: Stalling, hesitation, and difficulty starting can indicate a clogged fuel filter. Check the fuel pressure and inspect the fuel filter for debris.

Remember, regular filter replacement is key! Follow your vehicle manufacturer's recommended maintenance schedule. In harsh conditions (dusty environments, frequent short trips), you may need to replace filters more frequently.

Safety – Highlight Risky Components

Working with engine filters generally isn't too dangerous, but there are a few things to keep in mind:

- Hot Oil: When changing the oil filter, the oil can be very hot. Wear gloves and eye protection to avoid burns.

- Fuel System Pressure: When working with the fuel filter, be aware that the fuel system may be under pressure. Relieve the pressure before disconnecting any fuel lines to avoid fuel spills and potential fire hazards. Always disconnect the negative battery terminal before working on the fuel system.

- Proper Disposal: Dispose of used oil and filters properly. Oil and fuel are hazardous materials and should not be poured down drains or into the ground. Check with your local auto parts store or recycling center for disposal options.

Conclusion

Understanding the function and maintenance of engine filters is vital for keeping your engine running smoothly and efficiently. By following the information provided here and regularly inspecting and replacing your filters, you can extend the life of your engine and avoid costly repairs. Remember to consult your vehicle's owner's manual for specific filter replacement intervals and procedures.

We've got a detailed diagram available for download that visualizes all of this, showing flow paths, key components, and more. It's a great resource to have in your toolbox. Happy wrenching!