What Does An Engine Knock Mean

Engine knock, also known as detonation or pre-ignition, is a serious condition that can drastically reduce engine performance and lifespan. As experienced DIYers, understanding the causes, symptoms, and potential solutions to engine knock is crucial for maintaining your vehicle's health and preventing costly repairs. This article will delve into the technical aspects of engine knock, providing you with the knowledge to diagnose and potentially address this issue. We even have a helpful diagram available for download to further aid your understanding.

Purpose: Why Understanding Engine Knock Matters

Recognizing and addressing engine knock is vital for several reasons:

- Preventing Catastrophic Damage: Uncontrolled detonation can rapidly erode pistons, damage connecting rods, and even crack cylinder heads. Early intervention can prevent these severe consequences.

- Maintaining Performance: Knock retards ignition timing, reducing power output and fuel efficiency. Fixing the underlying cause restores optimal engine performance.

- Extending Engine Life: By preventing the stress and wear associated with knock, you can significantly prolong the life of your engine.

- Informed Modifications: If you're modifying your engine, understanding knock is essential to ensure your modifications don't inadvertently create a knock-prone environment.

Key Specs and Main Parts Involved

To understand engine knock, we need to consider these critical specifications and engine components:

- Compression Ratio: The ratio of the cylinder volume at its largest (piston at bottom dead center) to its smallest (piston at top dead center). Higher compression ratios increase the risk of knock.

- Air-Fuel Ratio (AFR): The ratio of air to fuel entering the engine. A lean mixture (too much air) can increase combustion temperatures and promote knock.

- Ignition Timing: The point in the engine cycle when the spark plug fires. Advancing timing (firing the plug earlier) increases power but also raises the risk of knock.

- Octane Rating: A measure of a fuel's resistance to knock. Higher octane fuels can withstand higher compression ratios and advanced timing.

- Engine Control Unit (ECU): The computer that controls the engine, including ignition timing and fuel injection.

- Knock Sensor: A sensor that detects engine vibrations indicative of knock. The ECU uses this information to retard ignition timing.

- Cylinders and Pistons: The heart of the engine where combustion occurs. Damage here due to knock is serious.

How It Works: The Mechanics of Engine Knock

Engine knock occurs when the air-fuel mixture in the cylinder ignites in an uncontrolled manner. Instead of a smooth, even burn initiated by the spark plug, pockets of unburned mixture spontaneously ignite due to excessive heat and pressure. This creates multiple flame fronts that collide, generating a sharp, metallic "knocking" or "pinging" sound.

Here's a more detailed breakdown:

- Normal Combustion: The spark plug ignites the air-fuel mixture, creating a single, expanding flame front that pushes the piston down.

- Knock (Detonation): As the piston compresses the mixture, heat and pressure rise. If certain conditions are met (high compression, lean mixture, excessive heat), pockets of unburned fuel-air mixture auto-ignite before the flame front from the spark plug reaches them.

- Pressure Waves: These multiple, uncontrolled ignitions create intense pressure waves that bounce around the cylinder. These waves collide, generating the characteristic "knocking" sound.

- Damage: The intense pressure spikes from detonation can damage pistons, connecting rods, spark plugs, and cylinder heads.

Pre-ignition, while often used interchangeably with detonation, is slightly different. Pre-ignition occurs when the air-fuel mixture ignites before the spark plug fires, typically due to a hot spot in the cylinder (e.g., a glowing piece of carbon deposit or an overheated spark plug). While the end result is similar (uncontrolled combustion and potential engine damage), the cause is different.

Real-World Use: Basic Troubleshooting Tips

If you suspect engine knock, here are some initial troubleshooting steps:

- Listen Carefully: Try to identify the sound. Knock typically sounds like a metallic pinging or rattling, often most noticeable under acceleration or load.

- Check Fuel Grade: Ensure you're using the correct octane fuel recommended for your vehicle. Try a higher octane fuel to see if the knock diminishes.

- Inspect Spark Plugs: Look for signs of overheating or damage. Replace them if necessary, using the correct heat range for your engine.

- Check for Vacuum Leaks: Vacuum leaks can lean out the air-fuel mixture, increasing the risk of knock. Inspect vacuum lines for cracks or disconnections.

- Inspect Cooling System: Overheating can exacerbate knock. Ensure your cooling system is functioning properly, including checking the coolant level and thermostat.

- Scan for Codes: Use an OBD-II scanner to check for any engine codes related to knock or other engine problems. A faulty knock sensor can sometimes trigger a code.

- Consider Carbon Buildup: Excessive carbon deposits in the combustion chamber can create hot spots and increase compression, leading to knock. Consider a fuel system cleaner or professional carbon cleaning service.

Safety: Highlight Risky Components

Working on engine components involves inherent risks. Pay particular attention to the following:

- Fuel System: Gasoline is highly flammable. Disconnect the fuel pump fuse or relay before working on the fuel system to prevent accidental fuel spillage.

- Electrical System: Disconnect the battery before working on electrical components to avoid electrical shock.

- Hot Engine Components: Allow the engine to cool completely before working on it. Exhaust manifolds and other engine parts can remain extremely hot for a long time.

- Moving Parts: Never put your hands near moving engine parts while the engine is running.

Diagram Details (Available for Download)

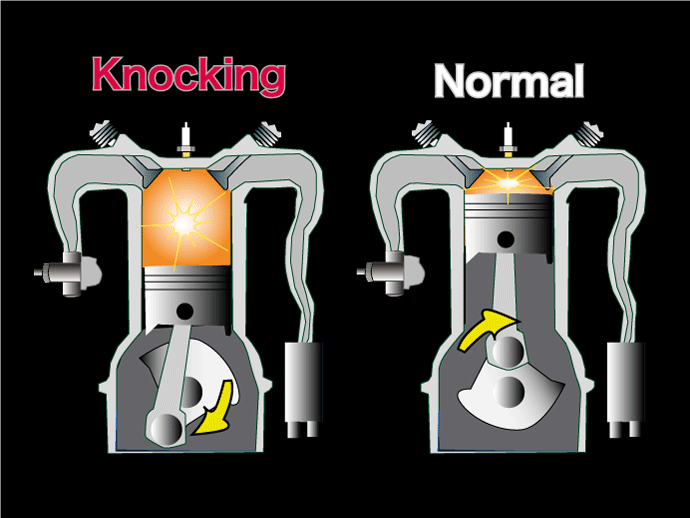

The diagram we've prepared provides a visual representation of the combustion process under both normal and knocking conditions. It helps to illustrate the key differences in flame propagation and pressure waves. Here's a brief overview of what you'll find in the diagram:

- Lines: Different colored lines indicate the flame front progression, pressure wave direction, and airflow.

- Colors: Colors represent different temperatures within the combustion chamber, with hotter areas indicated by red and orange.

- Icons: Icons represent the spark plug, piston, fuel injector, and knock sensor.

Please note that the diagram is a simplified representation and should be used in conjunction with this article and other reliable sources for a comprehensive understanding of engine knock. The actual combustion process is far more complex.

Engine knock is a complex issue with various potential causes. While these troubleshooting tips can help you identify and address some common problems, more complex cases may require professional diagnosis and repair. Remember to prioritize safety when working on your engine, and consult a qualified mechanic if you're unsure about any aspect of the repair process. Understanding the fundamentals of engine knock, however, empowers you to make informed decisions about your vehicle's maintenance and performance. Don't hesitate to consult your car's repair manual to get specific instructions. Good luck!