What Does An Iac Valve Do

So, you're diving into the mysteries of your engine, eh? Good on ya! Today, we're cracking open the case of the IAC valve, or Idle Air Control valve. This little fella is crucial for a smooth-running engine, especially at idle. We're going to break down what it does, how it works, and some basic troubleshooting tips to keep your ride humming.

Purpose: Understanding the IAC valve is super valuable for anyone doing their own car repairs or modifications. Knowing how it functions allows you to diagnose idle issues, potentially saving you money on shop visits. Plus, if you're modding your engine, you might need to adjust your IAC valve settings to compensate for performance upgrades. Let's say you changed the camshaft or installed a high flow air intake. You probably going to have to adjust the idle speed, and knowing about the IAC Valve operation will make your life much easier.

Key Specs and Main Parts

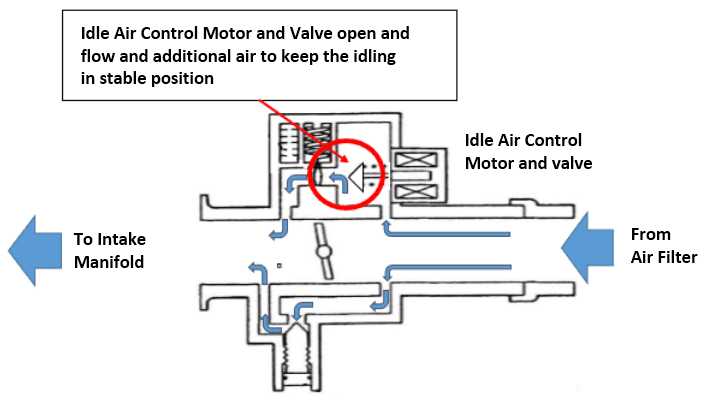

The IAC valve, also sometimes referred to as an idle speed control actuator, is an electromechanical device that controls the amount of air bypassing the throttle plate when the throttle is closed. This bypassing air keeps the engine running smoothly at idle. Here's a breakdown of the common components:

- Motor/Solenoid: This is the heart of the IAC valve. It receives signals from the Engine Control Unit (ECU) to open or close the valve. Different designs exist, including stepper motors and solenoids. A stepper motor incrementally rotates, precisely controlling the valve's position. A solenoid uses an electromagnet to retract or extend a plunger, opening or closing the valve.

- Valve/Plunger/pintle: This is the actual part that moves to regulate airflow. A plunger is usually a cylindrical or conical shaped part that moves inside the valve body, while a pintle is a needle shaped one.

- Valve Body: This houses the motor and valve, providing a passageway for the bypassing air.

- Electrical Connector: This connects the IAC valve to the vehicle's wiring harness and the ECU. The ECU sends signals to the IAC valve via this connector.

- Air Passages: These are the channels within the throttle body and IAC valve that allow air to bypass the throttle plate.

IAC Valve Types

There are two main types of IAC valves, each with its own method of operation:

- Stepper Motor IAC Valve: These use a stepper motor to precisely control the valve's position in small increments. They offer finer control over idle speed compared to solenoid-type valves.

- Solenoid IAC Valve: These use a solenoid to move a plunger or pintle in and out, opening or closing the valve. They are simpler in design but may not offer the same level of precision as stepper motor valves.

How It Works

The ECU monitors engine parameters like engine temperature, battery voltage, and engine load. It then uses this information to determine the optimal idle speed. Here's the sequence of events:

- Engine Starts: When you start your engine, the ECU activates the IAC valve to allow extra air into the engine, preventing it from stalling.

- Idle Speed Monitoring: The ECU continuously monitors the engine's RPM (revolutions per minute) via the crankshaft position sensor.

- Adjustment Signals: If the RPM is too low, the ECU signals the IAC valve to open further, allowing more air to bypass the throttle plate and increasing the idle speed. Conversely, if the RPM is too high, the ECU signals the IAC valve to close slightly, reducing airflow and lowering the idle speed.

- Closed-Loop Control: This process is a closed-loop system, meaning the ECU constantly adjusts the IAC valve based on feedback from the crankshaft position sensor, ensuring a stable idle speed.

- Load Compensation: When you turn on accessories like the air conditioner or headlights, they put an extra load on the engine. The ECU detects this load and signals the IAC valve to open further, compensating for the increased load and preventing the engine from stalling.

Real-World Use – Basic Troubleshooting Tips

Okay, your engine's acting up. Here are some common symptoms of a faulty IAC valve and some basic troubleshooting steps:

- Erratic Idle: The engine RPM fluctuates up and down, even when you're not touching the gas pedal.

- Stalling at Idle: The engine dies when you come to a stop or when idling.

- High Idle Speed: The engine idles at a much higher RPM than normal.

- Rough Idle: The engine feels shaky or vibrates excessively at idle.

Here's how to troubleshoot:

- Visual Inspection: Check the IAC valve for any visible damage or corrosion. Ensure the electrical connector is securely attached.

- Cleaning: A dirty IAC valve can cause it to stick or malfunction. Carefully remove the IAC valve and clean it with throttle body cleaner. Use a soft brush to remove any carbon buildup.

- Electrical Testing: Use a multimeter to check the resistance of the IAC valve's solenoid or motor. Compare your readings to the manufacturer's specifications. If the resistance is out of range, the IAC valve is likely faulty.

- Scan Tool: Use a scan tool to check for any Diagnostic Trouble Codes (DTCs) related to the IAC valve. The scan tool can also be used to monitor the IAC valve's operation and see if it's responding to commands from the ECU.

- Wiring Inspection: Check the wiring harness and connector for any signs of damage or corrosion. Use a test light or multimeter to verify that the IAC valve is receiving power and ground.

Important Note: Before attempting any electrical testing, disconnect the negative battery cable to prevent short circuits.

Safety – Highlight Risky Components

Working on your car can be rewarding, but it's crucial to be safe. Here are some safety considerations when dealing with the IAC valve:

- Electrical Components: The IAC valve is an electrical component, so avoid working on it with the ignition on. Disconnect the negative battery cable before performing any electrical tests.

- Hot Engine: Allow the engine to cool down completely before working on the IAC valve. Touching a hot engine can cause severe burns.

- Flammable Cleaners: Use throttle body cleaner in a well-ventilated area. Avoid spraying it near open flames or sources of ignition.

- Sharp Objects: Be careful when using tools to remove the IAC valve. Avoid using excessive force, which could damage the valve or surrounding components.

Disclaimer: This guide provides general information and troubleshooting tips for the IAC valve. Consult your vehicle's repair manual for specific instructions and safety precautions.

That's the basics of the IAC valve! By understanding how this component works, you're better equipped to diagnose and repair idle-related issues in your engine. Keep your hands clean, be careful, and happy wrenching!

We have a detailed diagram of a typical IAC valve system that you can download to further your understanding.