What Does Cc Mean In Engine Size

So, you’re looking to understand what “cc” means when we talk about engine size? Excellent! Knowing this isn’t just about impressing your buddies with technical jargon; it’s fundamental to understanding engine performance, choosing the right parts for modifications, and even diagnosing problems. This isn't some mystical number – it's a physical measurement, and understanding it unlocks a deeper understanding of your engine.

Why Understanding Engine Displacement Matters

Why bother learning about cubic centimeters? Well, for starters, it directly relates to an engine’s potential power output. It helps you:

- Compare Engines: Accurately compare the size and potential power of different engines. A 2.0L engine will generally produce more power than a 1.6L engine, all other factors being equal.

- Select the Right Parts: When modifying your engine (think bigger pistons, new crankshaft), you *need* to understand displacement to ensure compatibility and achieve desired performance gains. Incorrect parts can lead to catastrophic engine failure.

- Diagnose Problems: Understanding the relationship between displacement, compression ratio, and cylinder pressure helps diagnose issues like worn piston rings or leaky valves.

- Improve your knowledge: General understanding will go a long way in your car repair journey.

Think of it like this: you wouldn't attempt to bake a cake without understanding the recipe and ingredient quantities, right? Similarly, working on an engine requires a solid understanding of its fundamental specifications, and displacement is a cornerstone of that knowledge.

Key Specs and Main Parts: Unpacking the "cc"

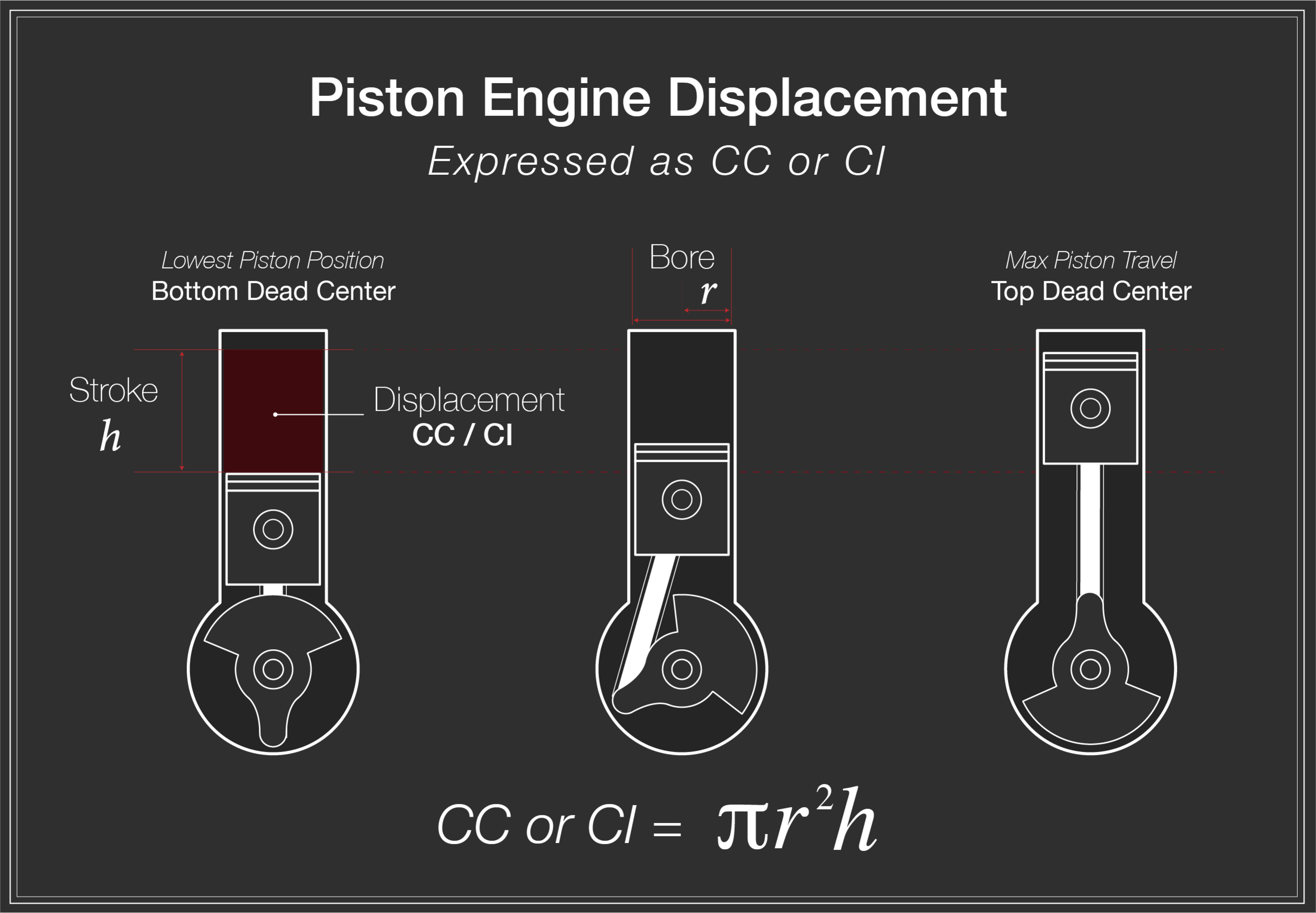

Okay, let's get technical. "cc" stands for cubic centimeters. It's a unit of volume. In the context of an engine, it refers to the total volume displaced by all the pistons inside the engine cylinders during one complete stroke. To calculate it, we need to understand a few key components and measurements:

Main Parts Involved:

- Cylinder: The cylindrical chamber where the piston moves up and down.

- Piston: The component that moves within the cylinder, driven by the expanding gases from combustion.

- Stroke: The distance the piston travels from its highest point (Top Dead Center or TDC) to its lowest point (Bottom Dead Center or BDC).

- Bore: The diameter of the cylinder.

Calculating Displacement:

The formula to calculate the displacement of a single cylinder is:

Cylinder Displacement = π * (Bore / 2)² * Stroke

Where:

- π (pi) is approximately 3.14159

- Bore is measured in centimeters.

- Stroke is measured in centimeters.

To get the total engine displacement, you simply multiply the cylinder displacement by the number of cylinders. For example, a four-cylinder engine with a cylinder displacement of 500cc per cylinder would have a total displacement of 2000cc (or 2.0 liters).

It's important to note that manufacturers often round the engine displacement figure for marketing purposes. A 1998cc engine might be advertised as a 2.0L engine.

Symbols and What They Mean

While there aren’t specific symbols directly related to “cc” or engine displacement in a traditional schematic diagram, understanding the symbols for the parts involved (cylinders, pistons, connecting rods, and crankshaft) is crucial. Here's a general overview:

- Cylinder: Often depicted as a simple cylinder or a cutaway showing the piston inside.

- Piston: Shown as a circular component moving within the cylinder. Lines may indicate piston rings.

- Connecting Rod: Connects the piston to the crankshaft. Usually shown as a solid line or a simplified representation.

- Crankshaft: A complex component that converts the linear motion of the pistons into rotary motion. Represented by a series of offset journals.

Colors are generally used to differentiate components and systems. For example:

- Red: Often used for high-pressure oil lines.

- Blue: May indicate coolant lines.

- Black: Typically used for general components or grounding wires.

Symbols are standardized, but variations exist. Always refer to the specific engine’s repair manual or schematic diagram for accurate interpretations.

How It Works: From Combustion to Crankshaft

Let’s briefly recap how engine displacement plays a role in the overall combustion process.

- Intake Stroke: The piston moves down, creating a vacuum that draws air and fuel mixture into the cylinder. The volume of the cylinder during this stroke is directly related to its displacement.

- Compression Stroke: The piston moves up, compressing the air-fuel mixture. The compression ratio (the ratio of cylinder volume at BDC to cylinder volume at TDC) is a critical factor influencing power output. Higher compression generally leads to more power, but also increases the risk of detonation (knocking).

- Combustion Stroke: The spark plug ignites the compressed mixture, causing a rapid expansion of gases that pushes the piston down. This is where the displacement volume *directly* impacts the force generated. A larger displacement allows for a larger volume of expanding gases, resulting in greater force on the piston.

- Exhaust Stroke: The piston moves up, pushing the burnt gases out of the cylinder through the exhaust valve.

The larger the engine displacement, the greater the amount of air and fuel that can be drawn into the cylinder, and the greater the force generated during combustion. This translates to more torque and horsepower.

Real-World Use: Basic Troubleshooting Tips

Understanding engine displacement can help you troubleshoot common issues:

- Power Loss: Significant power loss could indicate issues affecting cylinder filling or compression. Check for vacuum leaks, worn piston rings (leading to blow-by, where gases leak past the piston rings), or valve problems. A compression test can help pinpoint the source of the problem.

- Misfires: A misfire occurs when one or more cylinders fail to fire properly. This could be due to a faulty spark plug, fuel injector problem, or a compression issue in that specific cylinder. Knowing the engine's displacement and compression ratio helps you interpret compression test results accurately.

- Oil Consumption: Excessive oil consumption can be a sign of worn piston rings or cylinder walls. These issues directly impact the cylinder's ability to maintain a proper seal, leading to oil entering the combustion chamber.

Example: Let's say you have a 2.0L engine that's experiencing a significant power loss. A compression test reveals that one cylinder has significantly lower compression than the others. This points to a problem within that cylinder, such as worn piston rings or a leaky valve. Understanding the cylinder displacement and compression ratio allows you to accurately interpret the compression test results and focus your diagnostic efforts on the affected cylinder.

Safety: Know the Risky Components

Working on an engine involves risks. Here are some crucial safety precautions:

- Disconnect the Battery: Always disconnect the negative battery terminal before working on any electrical components.

- Hot Surfaces: Be extremely cautious of hot engine components, especially the exhaust manifold and catalytic converter. Allow the engine to cool completely before working on it.

- Fuel System: The fuel system is highly flammable. Work in a well-ventilated area and avoid sparks or open flames. Depressurize the fuel system before disconnecting any fuel lines.

- Rotating Parts: Keep hands, hair, and clothing away from rotating engine parts, such as the crankshaft and pulleys.

- Proper Lifting Techniques: Use appropriate lifting equipment (engine hoist, jack stands) and follow proper lifting techniques to avoid injuries. Never work under a vehicle supported only by a jack.

Critical Areas: When dealing with components related to engine displacement, pay special attention to the piston assembly (piston, rings, connecting rod) and the cylinder head (valves, camshaft). Mishandling or improper installation of these parts can lead to serious engine damage and potential injury.