What Does Cvt Mean On A Car

Alright, let's dive into understanding what CVT means on a car. For DIYers and enthusiasts, grasping the fundamentals of a Continuously Variable Transmission (CVT) is crucial, whether you're planning modifications, diagnosing issues, or simply expanding your automotive knowledge. This article will provide a solid technical overview, covering its purpose, components, functionality, and practical troubleshooting tips. Understanding the ins and outs of your car allows you to save money and ensure any problems are caught early.

Purpose of Understanding CVT Systems

Understanding a CVT system allows for better maintenance, informed repairs, and a greater appreciation for its unique operating characteristics. It's essential when diagnosing transmission problems and deciding if your car is right for you or future potential buyers.

Knowing the intricacies of the CVT system is beneficial in many ways. You'll be able to:

- Diagnose issues more accurately: Understand the symptoms and possible causes of CVT problems.

- Make informed repair decisions: Determine whether a repair is within your skill set or requires professional assistance.

- Perform preventative maintenance: Implement strategies to extend the life of your CVT.

- Appreciate the technology: Gain a deeper understanding of how your car achieves optimal efficiency.

Key Specs and Main Parts

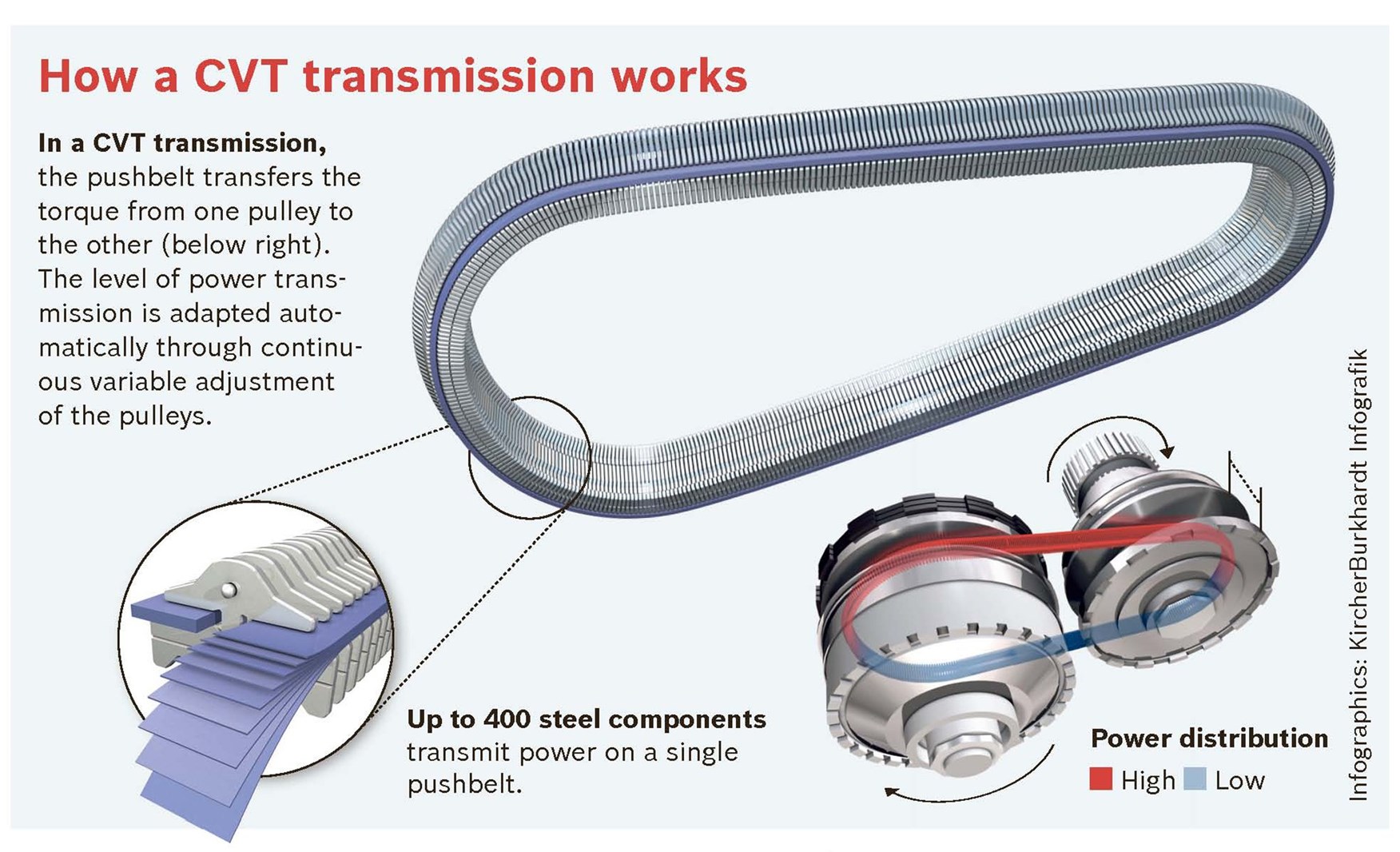

A CVT, unlike traditional automatic transmissions with fixed gears, offers an infinite range of gear ratios within its design parameters. The magic lies in its core components:

Main Components:

- Pulleys (Variators): The heart of the CVT system. These are cone-shaped pulleys that can change their effective diameter. There are usually two pulleys, a driving pulley connected to the engine and a driven pulley connected to the wheels.

- Belt or Chain: Connects the two pulleys. This belt or chain is usually made of high-strength steel and needs to withstand high tensile forces.

- Hydraulic Control System: Controls the position of the pulleys, thus adjusting the gear ratio. This is usually comprised of valves and solenoids.

- Transmission Control Unit (TCU): The brain of the CVT. It monitors various sensors (vehicle speed, throttle position, engine load) and commands the hydraulic control system to adjust the gear ratio for optimal performance and fuel efficiency.

- Torque Converter or Fluid Coupling: Used to transfer torque from the engine to the CVT input pulley, similar to a conventional automatic transmission. Some newer designs use a wet clutch pack instead of a torque converter for improved efficiency and responsiveness.

Key Specs:

- Gear Ratio Range: A critical specification that indicates the lowest and highest gear ratios the CVT can achieve. A wider range provides better acceleration and fuel economy.

- Torque Capacity: The maximum amount of torque the CVT can handle without damage. This is important for performance applications or vehicles with high-output engines.

- Belt/Chain Material: High-strength steel alloys are commonly used to withstand high tensile forces and friction.

- Fluid Type: CVT fluid is specifically formulated for CVT applications. Using the wrong fluid can cause severe damage.

How It Works

The essence of a CVT lies in its continuously variable gear ratios. Here's a breakdown of the operating principle:

- Engine Power Input: The engine's rotational force (torque) is transferred to the driving pulley through a torque converter or fluid coupling.

- Pulley Adjustment: The TCU monitors various sensors and commands the hydraulic control system to adjust the diameter of the driving and driven pulleys. When one pulley increases in diameter, the other decreases proportionally.

- Gear Ratio Variation: The ratio of the driving pulley diameter to the driven pulley diameter determines the gear ratio. By continuously adjusting these diameters, the CVT can seamlessly transition between a wide range of gear ratios.

- Power Output: The rotational force from the driven pulley is then transferred to the wheels through the differential and axles.

Imagine two cones facing each other, connected by a belt. Moving the belt up and down the cones changes the effective gear ratio. This is the basic principle behind a CVT. The TCU is constantly making adjustments to keep the engine operating at its most efficient point.

Real-World Use – Basic Troubleshooting Tips

CVTs are generally reliable, but like any mechanical system, they can experience problems. Here are some common issues and troubleshooting tips:

- Slipping: The engine revs high, but the car doesn't accelerate as expected. This could indicate a worn belt/chain, low fluid level, or a malfunctioning hydraulic control system. Check the fluid level and condition first. If the fluid is dark or burnt smelling, it needs to be changed.

- Jerking or Hesitation: Can be caused by a malfunctioning TCU, faulty sensors, or internal CVT damage. Scan the TCU for error codes using an OBD-II scanner.

- Noise: Unusual whining or grinding noises could indicate worn bearings or internal damage. This usually requires professional diagnosis and repair.

- Shuddering: Shuddering during acceleration can indicate CVT fluid degradation or a torque converter issue. Change the fluid following the manufacturer's recommendations.

Important Note: CVT fluid changes are crucial for maintaining the health of your CVT. Follow the manufacturer's recommended service intervals and use only the specified CVT fluid. Many CVTs do not have a traditional dipstick, so checking the fluid level may require specialized tools and procedures.

Safety – Highlight Risky Components

Working on a CVT can be dangerous if proper precautions aren't taken.

Safety First: CVTs contain high-pressure hydraulic systems and spinning components. Always disconnect the battery before working on any part of the transmission. Be extremely cautious when dealing with hydraulic lines and fittings. Always wear safety glasses and gloves.

Here are some specific safety concerns:

- High-Pressure Hydraulic System: The hydraulic control system operates at high pressure. Improperly disconnecting lines can result in fluid injection injuries. Consult a service manual for safe procedures.

- Spinning Components: The pulleys and belt/chain rotate at high speeds when the engine is running. Keep hands and tools clear of these components.

- Hot Surfaces: The transmission case and exhaust system can get extremely hot. Allow the engine and transmission to cool down before working on them.

- Fluid Handling: CVT fluid is slippery and can be harmful if ingested. Wear gloves and avoid contact with skin and eyes. Dispose of used fluid properly.

When replacing the CVT fluid, ensure that you do it according to the manufacturer's recommendations. Improper draining or filling can cause serious damage to the unit.

Access to Detailed Diagrams

For a complete understanding, a detailed CVT diagram would be highly beneficial. We have a high-resolution diagram file available for download. This diagram provides a visual representation of all the key components and their relationships, making it easier to understand the system's operation and troubleshoot problems.

Understanding the diagram is crucial, and you can use it to do the following:

- Trace the flow of power: Follow the path of torque from the engine to the wheels.

- Identify components: Locate specific parts within the system.

- Understand hydraulic circuits: Visualize the flow of hydraulic fluid.

- Plan repairs: Use the diagram to guide disassembly and reassembly.

With the detailed diagram and the knowledge gained from this article, you'll be well-equipped to tackle CVT-related tasks with confidence. Remember to always prioritize safety and consult a qualified mechanic if you're unsure about any procedure.