What Does Cvt Means In Cars

So, you're diving into the world of automotive transmissions and keep hearing about CVTs. Let's break down what a CVT, or Continuously Variable Transmission, actually *is*, how it works, and what you need to know about them if you're a hands-on car owner or modder. This article aims to give you a clear understanding of CVT technology, enabling you to better diagnose potential issues and perhaps even consider them for a project.

Purpose and Relevance

Understanding the workings of a CVT is crucial for several reasons. Whether you're diagnosing a slipping transmission, planning a custom engine swap, or just want to be a more informed car owner, knowing how this type of transmission operates will prove invaluable. Knowing the system allows you to efficiently tackle repairs and can greatly assist you with your vehicle maintenance.

Key Specifications and Main Parts

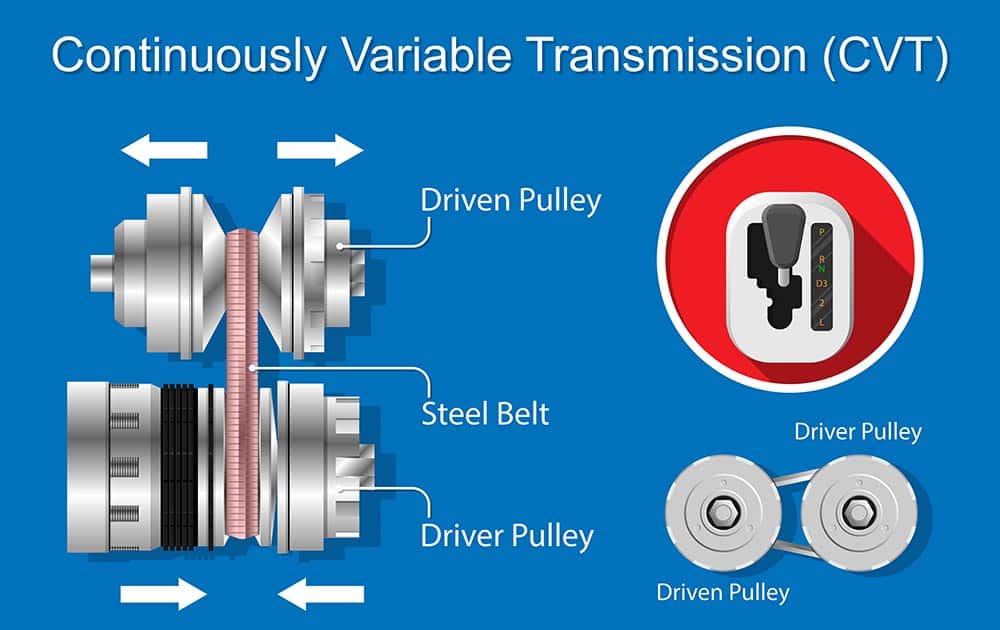

Unlike traditional automatic transmissions that use gears to provide discrete gear ratios, a CVT uses a system of belts and pulleys (or cones) to provide a virtually infinite number of gear ratios within a specific range. Here are the core components:

- Input Shaft: Connected to the engine's crankshaft, it transmits the engine's power into the CVT.

- Input Pulley (or Cone): Consists of two cones or sheaves that can move together or apart, altering their effective diameter. This is often called the "drive pulley."

- Output Pulley (or Cone): Similar to the input pulley, but connected to the driveshaft. This is often called the "driven pulley."

- Belt (or Chain): A high-strength belt or chain that connects the two pulleys. This transmits the power between the pulleys. The belt is arguably the heart of the system.

- Hydraulic Control System: A complex system of valves and actuators that control the positions of the pulleys, thereby changing the gear ratio. It uses transmission fluid pressure to adjust the pulley diameters.

- Electronic Control Unit (ECU): The "brain" of the CVT, the ECU receives data from various sensors (vehicle speed, engine speed, throttle position, etc.) and controls the hydraulic control system to optimize the gear ratio for performance and efficiency.

- Transmission Fluid: A specialized fluid designed for CVTs. It provides lubrication, cooling, and hydraulic pressure. Using the correct fluid is critical for CVT longevity.

How It Works

The fundamental principle of a CVT is quite elegant. Let's visualize the common pulley and belt system:

Imagine two cones facing each other with a belt running between them. If the belt is near the apex of the input cone (small diameter) and near the base of the output cone (large diameter), the output shaft will rotate slower than the input shaft, giving you a low gear ratio – good for acceleration. As the cones move, and the belt rides higher on the input cone and lower on the output cone, the gear ratio changes continuously, providing smooth, stepless acceleration.

The ECU monitors various sensors and commands the hydraulic control system to adjust the positions of the pulleys to achieve the desired gear ratio. For example:

- Acceleration: The ECU will command a lower gear ratio (high input pulley diameter, low output pulley diameter) for maximum torque.

- Cruising: The ECU will command a higher gear ratio (low input pulley diameter, high output pulley diameter) for optimal fuel efficiency.

Some CVTs also incorporate a "manual" mode that simulates discrete gear ratios. In this mode, the ECU restricts the range of available ratios and allows the driver to "shift" between them using paddle shifters or the gear lever.

Real-World Use and Troubleshooting

CVTs are known for their smooth acceleration and fuel efficiency, but they also have some potential drawbacks.

- Slipping: A common issue is belt slippage, which can be caused by a worn belt, low transmission fluid, or a malfunctioning hydraulic control system. Symptoms include hesitation, reduced acceleration, and a whining noise.

- Jerky Operation: Sometimes, the CVT can exhibit jerky operation, particularly at low speeds. This can be due to a faulty sensor, a malfunctioning valve in the hydraulic control system, or degraded transmission fluid.

- Overheating: CVTs can be susceptible to overheating, especially under heavy loads or in hot weather. This can damage the belt and other internal components. Consider adding an auxiliary transmission cooler if you frequently tow or drive in demanding conditions.

Basic Troubleshooting Tips:

- Check Transmission Fluid Level and Condition: Low or dirty fluid is a common cause of CVT problems. The fluid should be at the correct level and should be bright red and free of debris. If it's dark or smells burnt, it needs to be replaced. Always use the correct type of CVT fluid specified by the manufacturer.

- Scan for Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to check for any trouble codes. These codes can provide valuable clues about the nature of the problem.

- Inspect the Belt: While you can't directly inspect the belt without disassembling the CVT, listen for unusual noises (whining, slipping) that might indicate belt damage.

Safety Considerations

Working on a CVT can be hazardous. Here are some safety precautions to keep in mind:

- High Pressure: The hydraulic control system operates at high pressure. Before disconnecting any hydraulic lines, be sure to relieve the pressure to prevent fluid from spraying out and potentially causing injury.

- Hot Fluid: Transmission fluid can get very hot. Allow the CVT to cool down before draining the fluid to avoid burns.

- Heavy Components: The CVT itself is a heavy component. Use proper lifting equipment and techniques to avoid injury.

- Proper Support: Never work under a vehicle supported only by a jack. Always use jack stands.

- Electrical System: Disconnect the battery before working on any electrical components of the CVT.

Conclusion

While complex, understanding the basics of how a CVT functions can empower you to better maintain and diagnose issues with your vehicle. Remember to always consult your vehicle's repair manual and follow proper safety procedures when working on your car. With the right knowledge and tools, you can tackle many CVT-related tasks yourself. As an expert, it's my pleasure to inform you that we have a simplified schematic diagram of a typical CVT system. You can download it and use it for your educational and troubleshooting purposes. It provides a visual representation of the key components and their interconnections within the system.