What Does Cvt Stand For In Cars

So, you're looking to understand what CVT stands for in cars and how those transmissions work. Excellent! They're becoming increasingly common, and understanding them is crucial for modern car maintenance, diagnostics, and even considering certain modifications. This article will give you a solid foundation, covering the key concepts and even some basic troubleshooting.

What CVT Stands For and Why It Matters

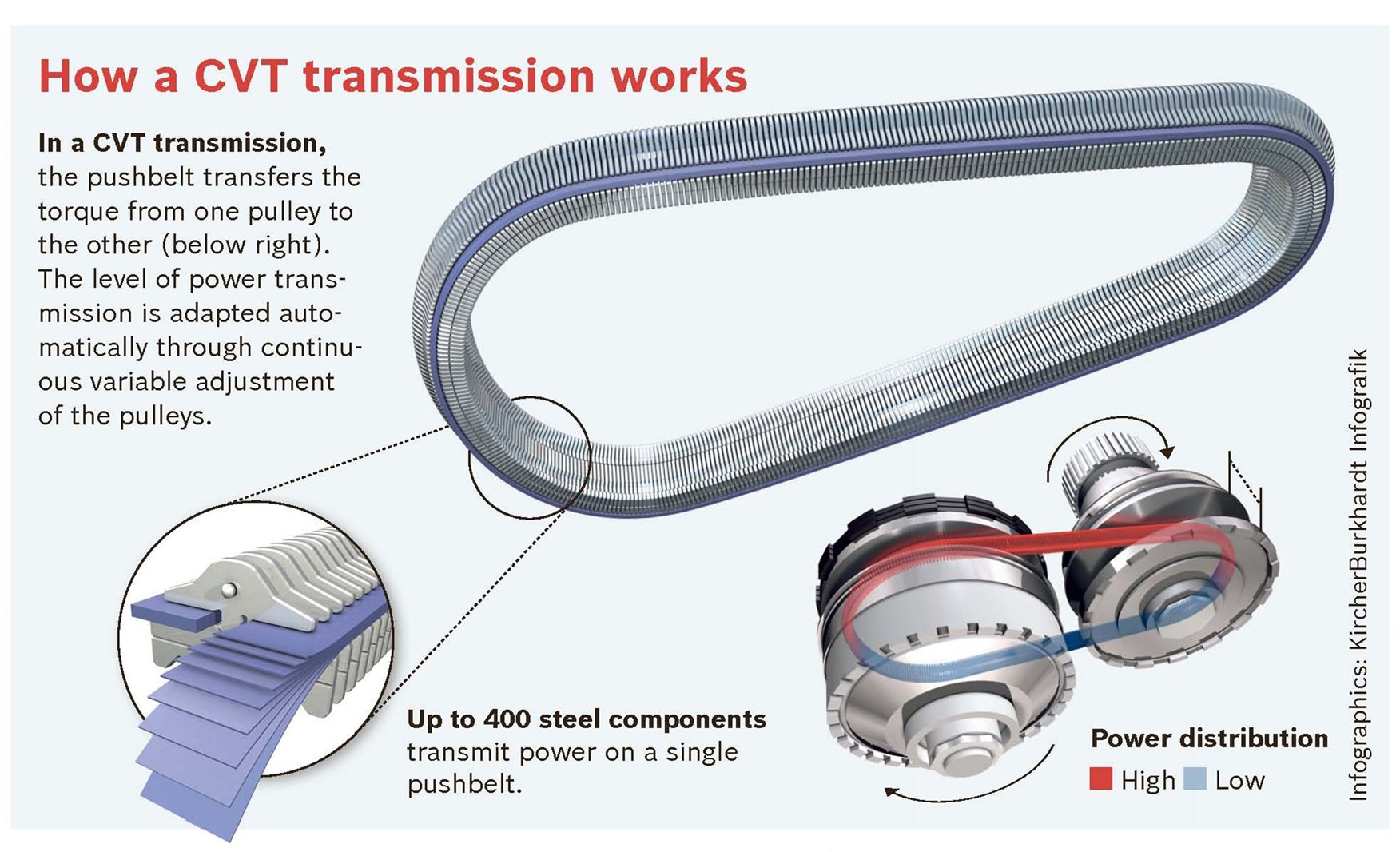

CVT stands for Continuously Variable Transmission. Unlike traditional automatic transmissions with a fixed number of gears, a CVT offers an infinite range of gear ratios within its operational range. This translates to potentially better fuel economy and smoother acceleration in many applications. Understanding how a CVT achieves this continuously variable ratio is the key to diagnosing issues and making informed decisions about your vehicle.

Why does understanding this matter? Let's say you're experiencing sluggish acceleration or unusual noises from your transmission. Knowing how a CVT operates and what its key components are can help you pinpoint the problem, potentially saving you hundreds (or even thousands) of dollars in diagnostic fees. Whether you're tackling a simple fluid change, investigating a warning light, or just expanding your automotive knowledge, understanding CVTs is a valuable asset.

Key Specs and Main Parts of a CVT

While specific CVT designs vary, the fundamental principle remains the same. Instead of gears, a CVT primarily utilizes:

- Input Pulley (Primary Pulley): Connected to the engine.

- Output Pulley (Secondary Pulley): Connected to the driveshaft.

- Belt (or Chain): A high-strength belt (often made of steel) or a chain connects the two pulleys. This is the core of the variable ratio system.

- Hydraulic Control System: Uses hydraulic pressure to adjust the effective diameter of the pulleys. This is the brain of the operation, constantly adjusting the ratios based on driver input and engine load.

- Transmission Control Unit (TCU): The computer that controls the hydraulic system, interpreting data from sensors and making adjustments to the pulleys.

- Valve Body: A complex hydraulic control unit containing solenoids and valves that regulate the flow of transmission fluid to control the pulley actuators.

Key Specs:

- Ratio Range: The maximum and minimum gear ratios the CVT can achieve. A wider range generally means better fuel economy and acceleration.

- Torque Capacity: The maximum torque the CVT can handle without damage. Critical for performance applications and avoiding premature failure.

- Fluid Type: CVTs require specific fluids designed for their unique operating conditions. Using the wrong fluid can lead to serious damage.

How a CVT Works: The Magic of Variable Ratios

The heart of the CVT is the variable-diameter pulleys. Each pulley consists of two cones facing each other. The belt (or chain) rides between these cones. The distance between the cones determines the effective diameter of the pulley. Here's the breakdown:

- Changing the Diameter: The hydraulic control system adjusts the distance between the cones in each pulley. When one pulley's diameter increases, the other pulley's diameter *decreases*, and vice versa. This is crucial to understand.

- Creating the "Gear" Ratio: Think of it like a bicycle. When you're in a low gear (small front sprocket, large rear sprocket), it's easier to pedal but you don't go as fast. In a CVT, this low gear is simulated when the input pulley has a small effective diameter and the output pulley has a large effective diameter.

- Continuously Variable: Unlike a bicycle with a set number of gears, the CVT can smoothly adjust the pulley diameters, resulting in a seamless transition between "gear" ratios. This is why it's called "continuously variable."

- TCU Control: The TCU monitors various sensors (engine speed, vehicle speed, throttle position, etc.) and uses this data to determine the optimal pulley diameters for the current driving conditions. It then signals the hydraulic control system to make the necessary adjustments.

Real-World Use: Basic Troubleshooting Tips

Here are a few common CVT issues and potential causes:

- Sluggish Acceleration: Could be due to low transmission fluid, a failing CVT belt/chain, or issues with the hydraulic control system (e.g., a stuck valve).

- Jerky Movement: Often indicates a problem with the TCU or the hydraulic control system's ability to smoothly adjust the pulleys. Dirty or degraded CVT fluid can also contribute.

- Whining Noise: A common sign of low transmission fluid or internal wear within the CVT. Can also indicate a failing CVT belt/chain.

- Warning Light (Check Engine/Transmission Light): Requires scanning the vehicle's computer for diagnostic trouble codes (DTCs). These codes will provide valuable clues about the nature of the problem.

Basic Troubleshooting Steps:

- Check Transmission Fluid Level and Condition: Low or dirty fluid is a common culprit. Follow your vehicle's maintenance schedule for fluid changes. Always use the specified CVT fluid.

- Scan for Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to retrieve any stored codes. Research these codes to understand the potential causes of the problem.

- Inspect the CVT for Leaks: Leaks can lead to low fluid levels and other issues.

Safety: Risky Components

Working on a CVT can be dangerous if proper precautions aren't taken. Here are some key safety considerations:

- High Pressure Fluid: The hydraulic control system operates at high pressure. Always relieve pressure before disconnecting any lines or components.

- Hot Components: The CVT gets very hot during operation. Allow it to cool down completely before working on it.

- Moving Parts: Never start the engine or operate the CVT with the transmission pan removed. There are many rapidly moving parts that can cause serious injury.

- Proper Support: Always use jack stands to support the vehicle securely before working underneath it.

- Specific Fluid: Using the wrong fluid can cause damage and may create unexpected behavior within the transmission during operation.

Diagrams and Further Information

Understanding the layout and components of your specific CVT model is crucial for effective diagnosis and repair. We have detailed diagrams of various CVT models available for download. These diagrams will show the location of sensors, hydraulic lines, and other key components. Knowing these locations, the sensors and the components will help during repair and troubleshooting.

Remember, this article provides a general overview of CVTs. Always consult your vehicle's service manual for specific information and procedures related to your particular make and model. If you're not comfortable working on your vehicle's transmission, it's always best to seek the assistance of a qualified mechanic.

Happy wrenching!