What Does Cvt Stand For On A Car

So, you've stumbled across the acronym "CVT" and want to know what it stands for on your car? Well, you've come to the right place. CVT stands for Continuously Variable Transmission. It's a type of automatic transmission that, unlike traditional automatics with fixed gears, offers a nearly infinite range of gear ratios. This article aims to give you a solid understanding of CVTs, their operation, and what you, as an experienced DIYer, need to know about them.

Purpose of Understanding CVTs

Why bother understanding CVTs? Several reasons. First, if your car has one (and many modern cars do), you'll be better equipped to diagnose potential issues. Second, understanding the principles of operation can help you drive more efficiently. Finally, and perhaps most importantly for the DIYer, knowing the components and their function is crucial for any sort of repair, maintenance, or even modification you might be considering. While extensive CVT repairs are often best left to professionals, understanding the basics allows you to perform fluid changes, inspect for leaks, and identify potential problems early. Plus, understanding the system enables you to intelligently communicate with a mechanic, ensuring you're not getting bamboozled with jargon.

Key Specs and Main Parts

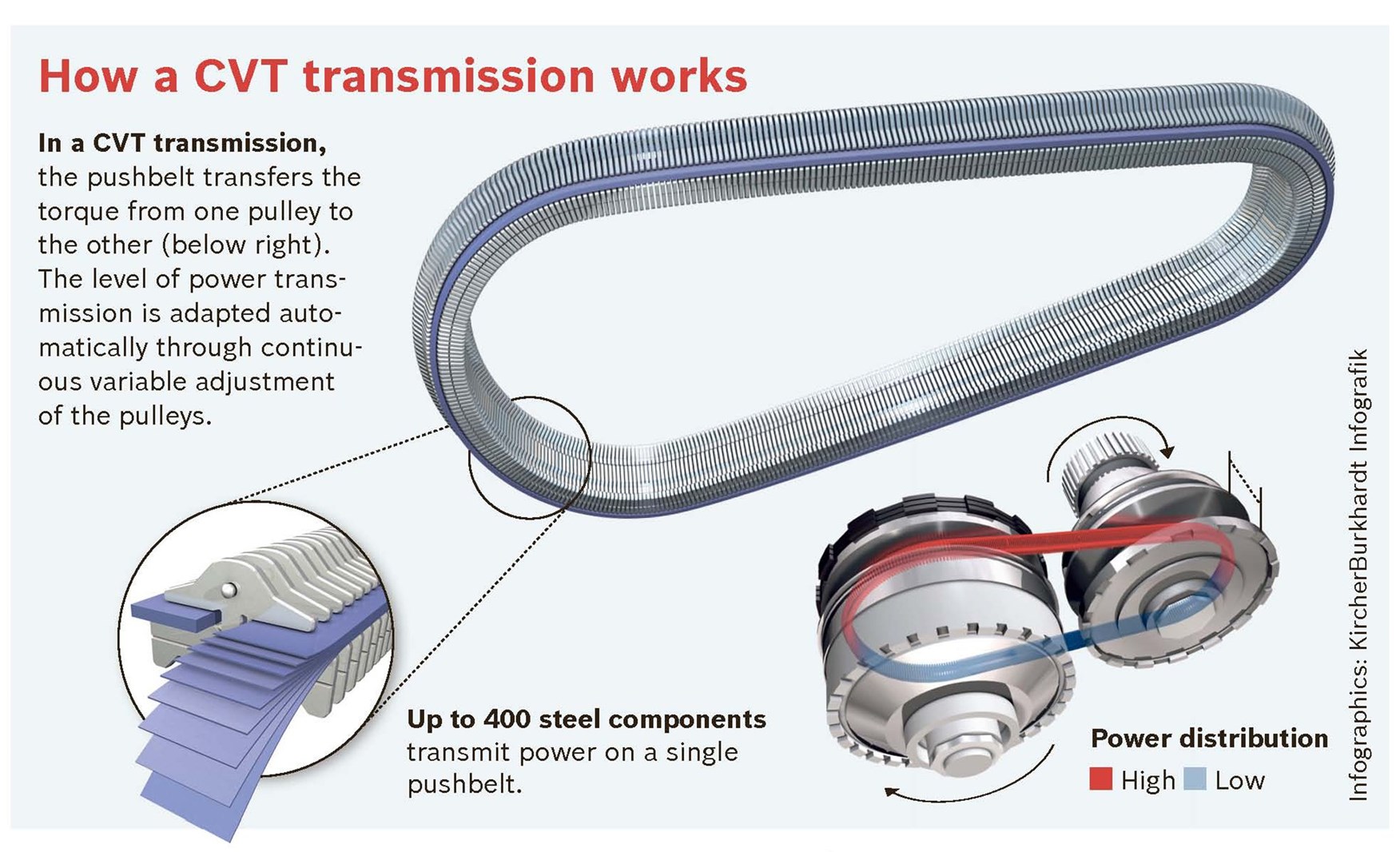

The core of a CVT is its ability to continuously vary the gear ratio. Instead of distinct gear steps, it provides a seamless transition through a range of ratios. Let's look at the key components that make this happen:

- Input Shaft: Connects to the engine's crankshaft.

- Output Shaft: Connects to the driveshaft and ultimately the wheels.

- Primary Pulley (Drive Pulley): Connected to the input shaft. This pulley's diameter is adjustable.

- Secondary Pulley (Driven Pulley): Connected to the output shaft. This pulley's diameter is also adjustable and operates in concert with the primary pulley.

- Belt or Chain: A high-strength belt (often made of steel) or chain connects the two pulleys. This belt is responsible for transferring power between the pulleys.

- Hydraulic Control System: A sophisticated hydraulic system (often computer-controlled) adjusts the diameter of the pulleys, thereby changing the gear ratio. This system utilizes sensors, valves, and a dedicated CVT fluid pump.

- CVT Fluid: Specialized fluid designed for the specific demands of a CVT. It provides lubrication, cooling, and hydraulic pressure for the pulley adjustment mechanism. Using the wrong fluid can severely damage a CVT.

- Sensors: Various sensors monitor parameters such as engine speed, vehicle speed, pulley positions, fluid temperature, and torque demands. These sensors feed information to the transmission control module (TCM).

- Transmission Control Module (TCM): The TCM is the brain of the CVT. It uses the sensor data to determine the optimal gear ratio and controls the hydraulic system accordingly.

How It Works

Imagine two cones facing each other, connected by a belt. That's a simplified analogy for a CVT. By moving the belt up and down these cones, you effectively change the diameter the belt is engaging, thus changing the gear ratio. In a real CVT, these "cones" are the adjustable pulleys. Let's break it down step-by-step:

- Starting from a Stop: The primary pulley is at its smallest diameter, and the secondary pulley is at its largest. This provides a low gear ratio, offering high torque for acceleration from a standstill.

- Acceleration: As the car accelerates, the hydraulic control system gradually increases the diameter of the primary pulley and decreases the diameter of the secondary pulley. This continuously increases the gear ratio.

- Cruising Speed: The CVT adjusts the pulley diameters to maintain the optimal gear ratio for fuel efficiency at the current speed.

- Deceleration: When decelerating, the process reverses. The primary pulley decreases in diameter, and the secondary pulley increases, providing engine braking.

The key to the CVT's smoothness is the continuous adjustment of the pulleys. There are no fixed gears to shift between, resulting in seamless acceleration and deceleration. The TCM constantly monitors the driving conditions and adjusts the pulley ratios to optimize performance and fuel economy.

Real-World Use – Basic Troubleshooting Tips

While complex CVT repairs require specialized tools and knowledge, there are some basic troubleshooting steps you can take:

- Check the CVT Fluid Level: Low fluid levels can cause slipping and erratic behavior. Consult your owner's manual for the correct procedure and fluid type.

- Inspect for Leaks: Look for signs of leaks around the transmission case, seals, and cooler lines. Leaks should be addressed promptly to prevent fluid loss and potential damage.

- Listen for Unusual Noises: Whining or grinding noises can indicate a problem with the belt, pulleys, or bearings.

- Check for Erratic Shifting or Slipping: If the CVT is not smoothly transitioning between ratios or is slipping under load, there may be an issue with the hydraulic control system, belt, or pulleys.

- Scan for Diagnostic Trouble Codes (DTCs): Use an OBD-II scanner to check for any stored DTCs related to the transmission. These codes can provide valuable clues about the nature of the problem. Remember that interpreting these codes often requires a service manual or database.

Note: Many CVT issues can be related to the fluid. Regular CVT fluid changes are crucial for maintaining the transmission's health. Follow the manufacturer's recommended service intervals.

Safety Considerations

Working on a CVT involves certain risks. Here's what you need to be aware of:

- Hot Fluid: CVT fluid can be extremely hot. Allow the transmission to cool down before working on it.

- High Pressure: The hydraulic control system operates at high pressure. Improperly disconnecting lines or components can result in serious injury.

- Lifting the Vehicle: Always use proper jack stands when working underneath a vehicle. Never rely solely on a jack.

- Electrical Components: The TCM and sensors are electrical components. Disconnect the battery before working on any electrical connections to prevent short circuits.

- CVT Fluid Disposal: Dispose of used CVT fluid responsibly. It is considered hazardous waste and should not be poured down drains or onto the ground.

Warning: CVT repairs can be complex and require specialized tools and knowledge. If you are not comfortable performing the work yourself, it is best to consult a qualified mechanic.

Working on the hydraulic control system can be particularly risky due to the high pressures involved. Incorrect disassembly or reassembly can lead to leaks, system malfunctions, or even injury. If you're unfamiliar with hydraulic systems, it's generally advisable to leave this aspect of CVT repair to a professional.

The belt or chain inside the CVT is also a critical component. Damage to the belt can lead to catastrophic transmission failure. Inspect the belt for wear, cracks, or damage during any internal CVT inspection. Replacing the belt usually requires specialized tools and expertise.

Finally, the CVT fluid itself is somewhat caustic and can cause skin irritation. Wear gloves and eye protection when handling CVT fluid.

In conclusion, understanding the continuously variable transmission in your car can be a great asset to your DIY skillset. From recognising potential issues to performing basic maintenance. We hope this article has given you a good grounding. As a final note, we have access to a detailed diagram of a typical CVT system, which you can download to aid your future projects and learning. Contact us for access to the file.