What Does Cylinder Mean For Cars

Alright, let's dive into the heart of your engine: the cylinders. Understanding what a cylinder is and how it functions is crucial whether you're tackling a simple repair, planning some serious modifications, or just trying to wrap your head around how your car actually moves. We're going to break down the cylinder, its components, how it works, and what you need to know to troubleshoot common issues. Think of this as your comprehensive guide to understanding the powerhouse inside your engine.

Purpose: Why Understanding Cylinders Matters

Why bother learning about cylinders? Because they are absolutely fundamental to engine operation. A solid grasp of cylinder function is invaluable for:

- Diagnostics and Repair: Identifying the source of engine problems like misfires, low compression, or excessive oil consumption often starts with understanding cylinder behavior.

- Performance Tuning: Modifying your engine for more power invariably involves manipulating cylinder parameters. Knowing what affects cylinder pressure, airflow, and combustion is vital.

- Preventative Maintenance: Detecting early signs of cylinder wear or damage can prevent catastrophic engine failure and save you thousands in repairs.

- General Understanding: Even if you don't plan on tearing down an engine, understanding how cylinders work allows you to better interpret engine behavior and make informed decisions about maintenance and modifications.

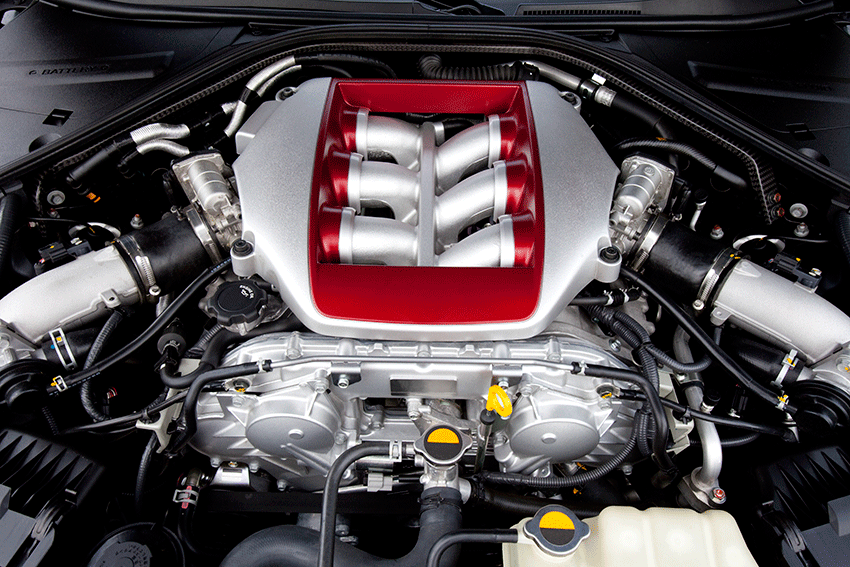

Key Specs and Main Parts

A cylinder is, at its most basic, a precisely machined cavity inside the engine block where combustion occurs. But there's a lot more to it than just a hole in the metal. Let's look at the major components:

- Cylinder Bore: The internal diameter of the cylinder itself. This is a critical dimension as it, along with the stroke (more on that below), determines the engine's displacement. Overboring a cylinder (increasing its diameter) is a common performance modification, but it requires careful machining and matching pistons.

- Piston: A cylindrical component that moves up and down inside the cylinder bore. It's connected to the connecting rod, which in turn is connected to the crankshaft. The piston's primary function is to convert the energy from combustion into mechanical motion. Key specs for a piston include its diameter, compression height (distance from the wrist pin to the top of the piston), and crown design.

- Piston Rings: These circular rings fit into grooves around the piston and seal against the cylinder wall. They serve several critical functions:

- Compression Rings: Seal the combustion chamber to prevent gases from escaping.

- Oil Control Rings: Scrape excess oil from the cylinder walls to prevent it from entering the combustion chamber and causing smoke.

- Connecting Rod (Con Rod): Connects the piston to the crankshaft. It transmits the force from the piston to the crankshaft, converting linear motion into rotary motion. Con rods need to be incredibly strong to withstand the immense forces generated during combustion.

- Crankshaft: A rotating shaft that converts the reciprocating motion of the pistons into rotary motion, which is then transmitted to the transmission and ultimately to the wheels. The crankshaft has offset journals where the connecting rods attach. The stroke of the engine is the distance the piston travels from its highest point (Top Dead Center or TDC) to its lowest point (Bottom Dead Center or BDC). The stroke is determined by the crankshaft design.

- Cylinder Head: Sits atop the engine block and seals the cylinders. It houses the valves, spark plugs (in gasoline engines), and often the camshaft. The cylinder head is crucial for controlling airflow into and out of the cylinders.

- Valves: Control the flow of intake air/fuel mixture into the cylinder (intake valves) and the exhaust gases out of the cylinder (exhaust valves). Valve timing and lift (how far the valves open) are critical factors in engine performance.

- Spark Plug (Gasoline Engines): Ignites the air/fuel mixture in the cylinder, initiating the combustion process.

- Fuel Injector (Most Modern Engines): Sprays fuel into the intake port or directly into the cylinder, depending on the engine design.

How It Works: The Four-Stroke Cycle

Most modern car engines operate on a four-stroke cycle. Here's a breakdown of each stroke:

- Intake Stroke: The piston moves down the cylinder, creating a vacuum. The intake valve opens, and the air/fuel mixture (or just air in direct injection engines) is drawn into the cylinder.

- Compression Stroke: The piston moves back up the cylinder, compressing the air/fuel mixture. Both the intake and exhaust valves are closed. This compression increases the temperature and pressure of the mixture, making it easier to ignite.

- Combustion (Power) Stroke: At or near the top of the compression stroke, the spark plug ignites the compressed air/fuel mixture. The resulting explosion forces the piston down the cylinder with great force. This is the stroke that produces the engine's power.

- Exhaust Stroke: The piston moves back up the cylinder, pushing the burnt exhaust gases out of the cylinder through the open exhaust valve.

Real-World Use: Basic Troubleshooting Tips

Knowing how cylinders work can help you diagnose engine problems. Here are a few examples:

- Misfire: A misfire occurs when one or more cylinders fails to fire properly. This can be caused by a faulty spark plug, a bad ignition coil, a clogged fuel injector, low compression (due to worn rings or valves), or a vacuum leak. A cylinder compression test can help pinpoint the problem cylinder.

- Low Compression: Indicates a leak in the cylinder. This could be due to worn piston rings, leaking valves, or a blown head gasket. A compression test or a leak-down test can help diagnose the source of the leak.

- Excessive Oil Consumption: Often caused by worn piston rings or valve stem seals, allowing oil to enter the combustion chamber and burn. A compression test and visual inspection of the spark plugs can provide clues.

- Knocking/Pinging: Can be caused by pre-ignition or detonation in the cylinders. This can be due to using low-octane fuel, excessive carbon buildup in the cylinders, or an overheated engine.

Safety: Highlight Risky Components

Working on engines involves inherent risks. Be especially careful when dealing with these components:

- Fuel System: Fuel is highly flammable. Always disconnect the battery and take precautions to prevent sparks when working on the fuel system.

- Electrical System: The ignition system can generate high voltages. Disconnect the battery and be careful when handling ignition components.

- Rotating Parts: Keep your hands and clothing clear of rotating parts like the crankshaft and camshaft when the engine is running.

- Hot Surfaces: Exhaust manifolds and other engine components can get extremely hot. Allow the engine to cool down before working on it.

- Springs: Valve springs are under tremendous pressure and can be dangerous if released unexpectedly. Use appropriate valve spring compressors when working on valve trains.

Always remember to consult your vehicle's service manual for specific procedures and safety precautions.

By understanding the fundamental principles outlined here, you're well-equipped to tackle more complex automotive tasks with confidence. Good luck, and wrench responsibly!