What Does Dohc Mean On A Car

If you're diving into the world of engine performance and modifications, you've undoubtedly encountered the term "DOHC." It's a common abbreviation found on valve covers, in engine specifications, and tossed around in car enthusiast conversations. But what does DOHC really mean, and why should you care? This article breaks down the DOHC system, explaining its purpose, components, operation, and how understanding it can help you diagnose and troubleshoot engine issues. We'll aim for a clear, technically accurate explanation suited for the experienced DIYer.

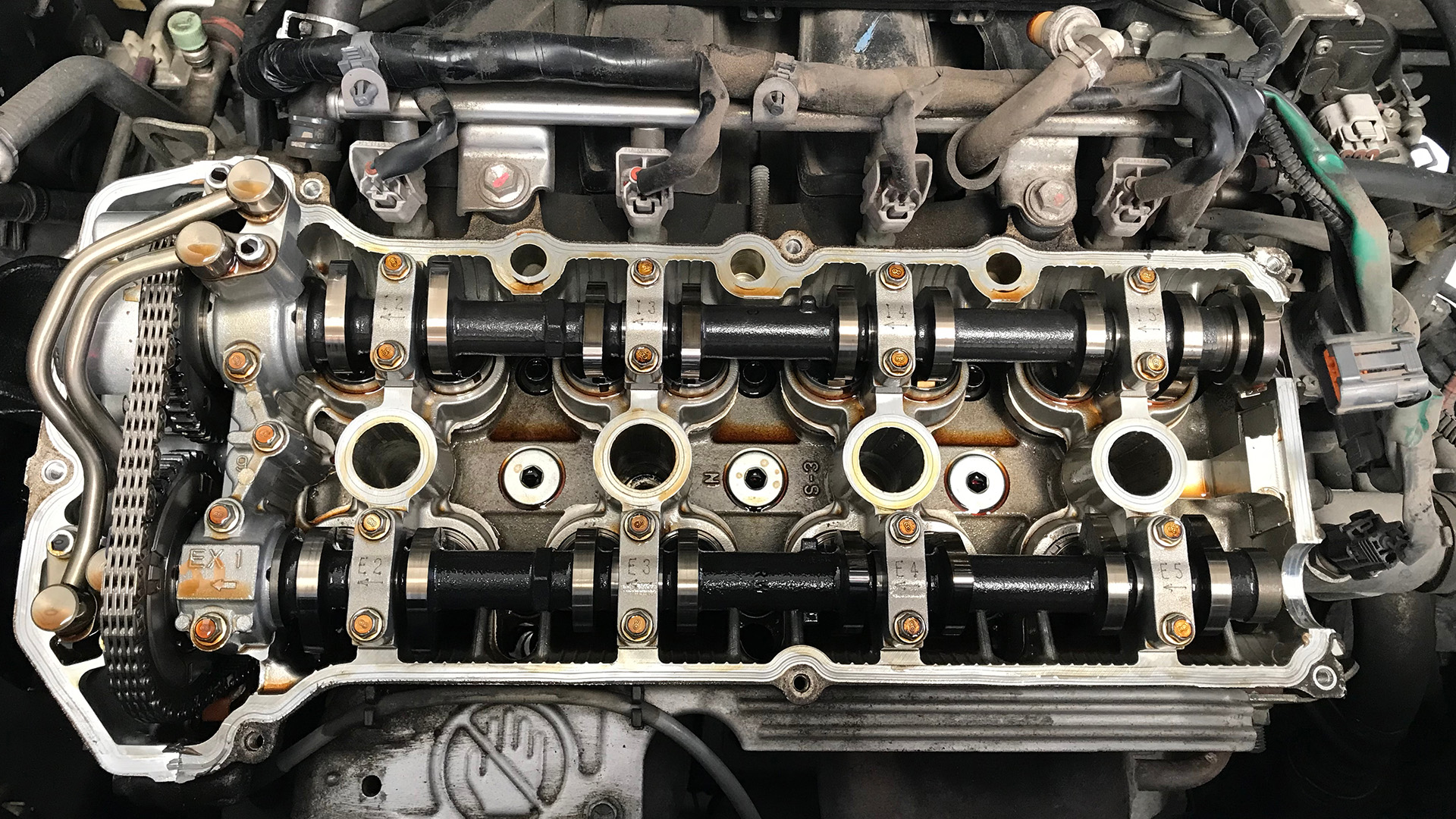

Understanding DOHC: Double Overhead Camshaft

DOHC stands for Double Overhead Camshaft. To fully grasp this, let's break down the individual parts. The camshaft is a rotating shaft that contains lobes (called cams). These cams press on valves, opening them at precisely timed intervals to allow air and fuel into the cylinders (intake valves) and exhaust gases to escape (exhaust valves). In a traditional engine, the camshaft(s) may be located inside the engine block, actuating the valves via pushrods and rocker arms. This is called an overhead valve (OHV) or pushrod engine.

An overhead camshaft (OHC) engine, on the other hand, positions the camshaft(s) directly above the cylinder head. This eliminates the need for pushrods, leading to a more direct and responsive valve actuation. A DOHC engine takes this a step further by using two camshafts, one dedicated to controlling the intake valves and another for the exhaust valves.

Purpose: Why DOHC Matters

The primary reason for using a DOHC configuration is to improve engine performance and efficiency. Here's why:

- Improved Valve Control: DOHC allows for more precise control over valve timing and lift. Each camshaft can be optimized for its specific set of valves.

- Greater Valve Area: Having two camshafts makes it easier to accommodate more valves per cylinder (typically four – two intake and two exhaust). More valves mean greater airflow into and out of the cylinder, leading to increased power.

- Higher Engine Speeds: The lighter valve train (compared to pushrod engines) allows for higher engine speeds (RPM) without valve float (where the valves don't close completely due to inertia).

- More Efficient Combustion: Better airflow and valve control contribute to more complete and efficient combustion, resulting in improved fuel economy and reduced emissions.

Key Specs and Main Parts

A DOHC system consists of several crucial components:

- Camshafts (Intake and Exhaust): These hardened steel shafts contain the cams that actuate the valves. The cam profile (shape) dictates the valve lift (how far the valve opens) and duration (how long the valve stays open).

- Valves (Intake and Exhaust): These open and close to control the flow of air/fuel mixture into the cylinder and exhaust gases out of the cylinder.

- Valve Springs: These keep the valves closed when not being actuated by the camshaft.

- Valve Lifters (or Tappets): These are located between the camshaft and the valve stem. They can be hydraulic (using oil pressure to maintain zero lash) or mechanical (requiring periodic adjustment).

- Timing Belt or Chain: This connects the crankshaft to the camshaft(s), ensuring that the valves open and close in sync with the piston movement. This is absolutely crucial; incorrect timing can lead to severe engine damage.

- Camshaft Sprockets (or Gears): These are attached to the camshafts and are driven by the timing belt or chain.

- Variable Valve Timing (VVT) System (Optional): Many modern DOHC engines incorporate VVT systems, which allow the camshaft timing to be adjusted dynamically to optimize performance across a wider range of engine speeds.

A typical DOHC engine will have four valves per cylinder - two intake and two exhaust. Some high-performance engines may even have five valves per cylinder (three intake and two exhaust), further increasing airflow.

How It Works

The operation of a DOHC engine is relatively straightforward once you understand the function of each component:

- The crankshaft rotates as the pistons move up and down in the cylinders.

- The timing belt or chain, driven by the crankshaft, rotates the intake and exhaust camshafts.

- As the camshafts rotate, the cams press down on the valve lifters (tappets).

- The valve lifters push the valves open, allowing air and fuel to enter the cylinder (intake stroke) or exhaust gases to exit (exhaust stroke).

- The valve springs return the valves to their closed position after the cam lobe has rotated past the valve lifter.

- The process repeats continuously as the engine runs, with the valves opening and closing in precise synchronization with the piston movement.

Variable Valve Timing (VVT) systems add another layer of complexity. These systems typically use hydraulic actuators to adjust the position of the camshaft(s) relative to the crankshaft. This allows the engine control unit (ECU) to optimize valve timing for different driving conditions, such as maximizing torque at low RPM or increasing horsepower at high RPM.

Real-World Use – Basic Troubleshooting Tips

Understanding the DOHC system can be incredibly helpful in diagnosing engine problems. Here are a few common issues and how knowledge of the DOHC system can aid in troubleshooting:

- Rough Idle or Misfires: Could be caused by a vacuum leak, faulty spark plugs or incorrect valve timing. A stretched timing chain or a malfunctioning VVT system can disrupt valve timing. Checking the timing marks on the crankshaft and camshaft sprockets is crucial.

- Loss of Power: A clogged air filter, faulty fuel injectors, or worn camshaft lobes can cause a loss of power. Inspecting the camshaft lobes for wear is essential. A compression test can also reveal valve issues.

- Ticking Noise: Often caused by excessive valve lash (clearance between the valve lifter and the valve stem). This requires adjusting the valve lash to the specified tolerance.

- Check Engine Light (CEL): The CEL can be triggered by a variety of issues, including problems with the VVT system. Scanning the ECU for diagnostic trouble codes (DTCs) is the first step in troubleshooting.

When troubleshooting, always refer to the vehicle's service manual for specific diagnostic procedures and repair instructions.

Safety – Highlight Risky Components

Working on a DOHC engine involves dealing with several potentially dangerous components:

- Timing Belt/Chain: Incorrect installation or adjustment of the timing belt/chain can lead to catastrophic engine damage. Ensure the engine is at top dead center (TDC) on the compression stroke before removing or installing the timing belt/chain. Always double-check the timing marks.

- Valve Springs: Valve springs are under considerable tension and can cause serious injury if they are released unexpectedly. Use proper valve spring compressors when removing or installing valve springs.

- High-Pressure Oil System (VVT): The VVT system operates with high-pressure oil. Be careful when disconnecting oil lines, as residual pressure can cause oil to spray out.

- Rotating Parts: Never work on the engine while it is running, and always disconnect the battery to prevent accidental starting.

It is essential to follow all safety precautions and use appropriate tools and equipment when working on a DOHC engine. If you are not comfortable performing a particular task, it is best to seek the assistance of a qualified mechanic.

Conclusion

Understanding the DOHC system is crucial for anyone interested in engine performance and maintenance. By understanding the function of each component and how the system operates, you can better diagnose and troubleshoot engine problems and potentially save yourself time and money on repairs. While working on these systems can be complex, a solid understanding of the fundamentals, combined with the right tools and resources, will equip you with the knowledge and confidence to tackle many engine-related tasks.

[Download link to generic DOHC diagram will be here]. We have a detailed, generic diagram of a typical DOHC engine, illustrating all key components mentioned in this article. You can download it for reference. Please note this is a generic diagram; always refer to your specific vehicle's service manual for accurate information.