What Does Front Wheel Drive Mean

Welcome, fellow gearheads! Today, we're diving deep into the mechanics of front-wheel drive (FWD). Whether you're planning a DIY repair, considering a performance upgrade, or simply expanding your automotive knowledge, understanding how FWD works is crucial. We'll break down the system, identify key components, and provide real-world troubleshooting tips. Plus, we've got a detailed diagram you can download to reference as you work (link at the end!). Let's get started.

Purpose of Understanding FWD

Why bother learning the ins and outs of FWD? The answer is multifaceted. For starters, a solid understanding of FWD systems will equip you to perform basic maintenance and repairs yourself, saving you money and increasing your confidence under the hood. Furthermore, if you're considering modifying your FWD vehicle, knowing its limitations and strengths is paramount to achieving your desired performance goals without causing catastrophic damage. Finally, even understanding the basic principles will help you diagnose problems more effectively and communicate more clearly with your mechanic, ensuring you get the right repairs done at the right price.

Key Specs and Main Parts

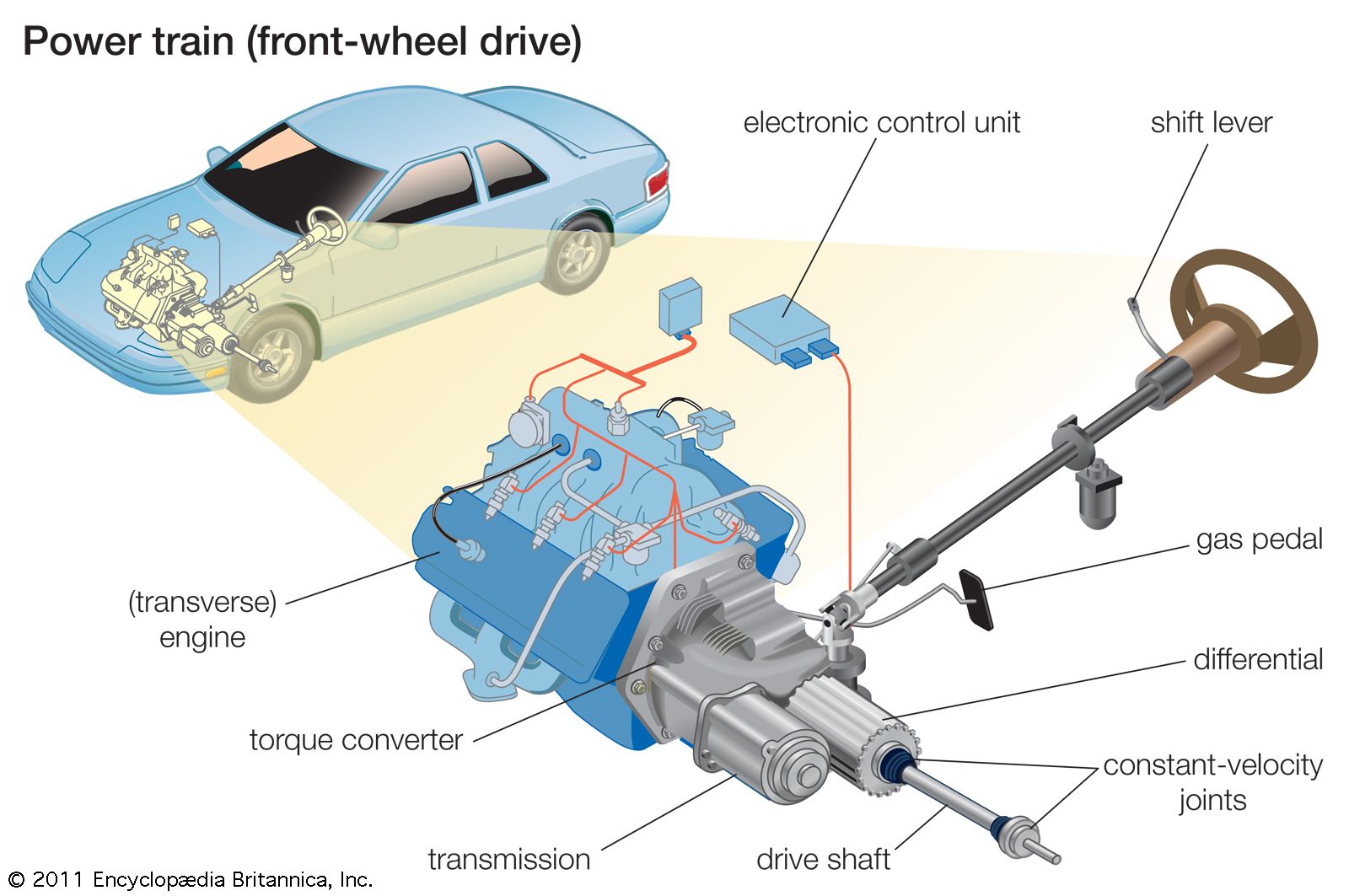

A FWD system integrates the engine, transmission, and drive axles into a relatively compact unit, primarily located at the front of the vehicle. Here's a breakdown of the core components:

- Engine: Provides the power, usually a gasoline or diesel internal combustion engine. Torque is the key output from the engine, the rotational force that drives the wheels.

- Transmission (Transaxle): In FWD vehicles, the transmission is typically integrated with the differential into a single unit called a transaxle. The transmission's job is to manage engine speed and torque output, converting the engine's power into usable force at the wheels. It contains multiple gears that allow for different torque multiplication ratios.

- Differential: Allows the drive wheels to rotate at different speeds, which is essential for turning. Without a differential, the inside wheel would have to spin at the same speed as the outside wheel during a turn, causing binding, tire slippage, and potentially damaging the drivetrain.

- Drive Axles (Half-Shafts): Transfer power from the differential to the front wheels. They consist of shafts, constant velocity (CV) joints, and boots. CV joints allow the axles to articulate and transmit power smoothly even when the suspension is moving and the wheels are turning.

- CV Joints and Boots: As mentioned, CV joints are crucial. They are packed with grease to reduce friction and are protected by rubber boots. Damage to these boots allows dirt and moisture to enter, leading to rapid wear and eventual failure of the CV joint.

- Wheel Bearings: Located inside the wheel hubs, wheel bearings allow the wheels to rotate freely with minimal friction. These are also crucial to the safety and performance of your vehicle.

Understanding the Diagram: Symbols, Lines, and Colors

A typical FWD diagram will use various symbols to represent different components and their relationships. Here's a general guide:

- Solid Lines: Typically represent mechanical connections, such as shafts and axles.

- Dotted Lines: Often indicate control linkages, vacuum lines, or electrical wiring.

- Different Colors: Can be used to distinguish different systems or flow paths (e.g., oil flow, coolant flow).

- Arrows: Indicate the direction of force or motion (e.g., power flow, rotation).

- Specific Icons: The diagram will use icons for the engine (usually a stylized engine block), transmission (a gear symbol), differential (a cage with gears), and CV joints (typically a symbol resembling a U-joint or ball joint).

Always consult the specific legend accompanying the diagram for precise symbol definitions. Manufacturers may use slightly different conventions.

How It Works: Power Flow in a FWD System

The power flow in a FWD system is relatively straightforward:

- The engine generates power through the combustion of fuel.

- This power is transmitted as torque to the transmission (transaxle).

- The transmission uses gears to adjust the torque and speed, allowing the engine to operate efficiently across a range of vehicle speeds.

- The output of the transmission goes to the differential.

- The differential splits the torque and allows the front wheels to rotate at different speeds during turns.

- Finally, the drive axles (half-shafts) transfer the power from the differential to the individual front wheels, propelling the vehicle forward.

The key advantage of FWD is packaging efficiency. By combining the engine, transmission, and drive system into a single unit at the front, manufacturers can create more interior space, especially in smaller vehicles. This design also contributes to good traction on slippery surfaces because the weight of the engine is directly over the driving wheels.

Real-World Use: Basic Troubleshooting Tips

Here are a few common issues you might encounter with a FWD system and how to diagnose them:

- Clicking or Popping Sounds While Turning: This is a classic symptom of a failing CV joint. Inspect the CV joint boots for cracks or tears. If the boot is damaged, replace it immediately to prevent further damage. If the clicking continues after boot replacement, the CV joint itself is likely worn and needs replacement.

- Vibrations at High Speeds: Could indicate worn wheel bearings, unbalanced tires, or a damaged drive axle. Start by having your tires balanced. If the vibration persists, inspect the wheel bearings for play or noise. Finally, check the drive axles for any signs of damage or excessive play in the CV joints.

- Difficulty Shifting Gears: May indicate a problem with the transmission itself, the clutch (in manual transmissions), or the shift linkage. Check the transmission fluid level and condition. Inspect the shift linkage for any binding or looseness. If the problem persists, further diagnosis of the transmission is required.

- Excessive Tire Wear (Front): Can be caused by misalignment, worn suspension components, or improper tire inflation. Have your alignment checked and adjusted by a qualified technician. Inspect the suspension components (ball joints, tie rod ends, struts) for wear or damage.

Important Note: Before attempting any repairs, consult your vehicle's repair manual for specific instructions and torque specifications.

Safety First: Risky Components and Precautions

Working on a FWD system involves dealing with several potentially dangerous components. Here are some key safety considerations:

- Springs and Struts: Coil springs are under tremendous pressure and can cause serious injury if mishandled. Always use proper spring compressors when removing or installing struts.

- Jacking and Supporting the Vehicle: Never work under a vehicle supported only by a jack. Always use jack stands placed on designated support points.

- Transmission Fluid: Some older transmission fluids can be harmful if ingested or come into contact with skin. Wear gloves and avoid contact with your eyes.

- Sharp Edges and Hot Surfaces: Be aware of sharp edges on metal components and allow the engine and exhaust system to cool completely before working on them.

- Airbags: When working around the steering or dashboard, always disconnect the battery and wait at least 15 minutes before proceeding to prevent accidental airbag deployment.

By following these safety precautions, you can minimize the risk of injury and ensure a safe and successful repair experience.

We hope this deep dive into front-wheel drive has been helpful. Remember to always prioritize safety and consult your vehicle's repair manual for specific instructions.

As promised, we have a detailed diagram available for download. It visually represents everything we discussed and will be a valuable asset during your DIY endeavors. (Link to Downloadable Diagram Here)