What Does Fwd Mean For Cars

Alright folks, let's dive deep into understanding FWD – Front-Wheel Drive – in cars. This isn't just about knowing your car moves; it's about understanding how that power gets to the pavement, which is crucial for everything from basic maintenance to more advanced modifications.

Purpose of Understanding FWD

Why bother learning about FWD? Well, several reasons come to mind. First, having a solid grasp of your car's drivetrain system is essential for performing even basic repairs like replacing axles or understanding why you're experiencing wheel spin in certain conditions. If you're planning any modifications, especially performance-related ones, you need to know how FWD affects your car's handling and power delivery. Furthermore, understanding FWD helps you diagnose issues more effectively, potentially saving you money on unnecessary mechanic visits. We're talking about being able to identify a failing CV joint before it completely disintegrates and leaves you stranded. And finally, it is just pretty cool to learn how all these different components work together.

Key Specs and Main Parts of a FWD System

A Front-Wheel Drive system, at its core, is all about putting the engine's power to the front wheels. This means that the engine, transmission, and differential are all usually grouped together in the front of the car. Here’s a breakdown of the key components:

- Engine: The heart of the operation, generating the power that drives everything. It converts fuel into mechanical energy, measured in horsepower (hp) and torque (lb-ft or Nm).

- Transmission: This is the gearbox that manages the engine's power output, translating it into the right amount of speed and torque for the wheels. Common types include manual transmissions (MT) and automatic transmissions (AT).

- Differential: The differential allows the front wheels to rotate at different speeds when turning. Without it, the inside wheel would drag during turns, causing instability and tire wear. In many FWD cars, the differential is integrated within the transmission casing, sometimes called a transaxle.

- Axles (or Half-Shafts): These are the shafts that transmit the power from the differential to the wheels. They’re equipped with CV (Constant Velocity) joints on both ends to allow for suspension movement and steering. CV joints are critical for smooth power delivery, even when the suspension is working hard.

- CV Joints (Constant Velocity Joints): These joints connect the axles to the wheels and the differential. They allow the axles to move up and down with the suspension and also allow the wheels to turn. There are typically two CV joints per axle: an inner joint (near the differential) and an outer joint (near the wheel).

- Hubs: These are the central part of the wheel that attaches to the axle. The wheel bearings are housed within the hub.

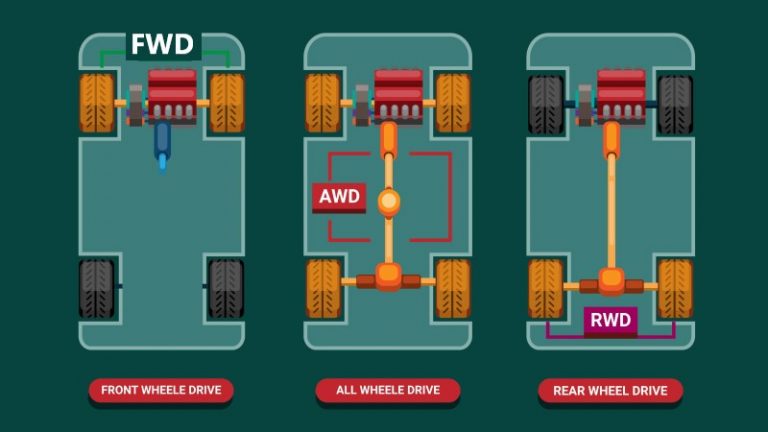

Understanding a FWD Diagram

Imagine a blueprint of your car's FWD system. The diagram shows the relationships between all of these components. Although symbols may vary slightly between manufacturers, there are some common conventions you’ll see:

- Solid Lines: These generally represent mechanical connections – axles, shafts, linkages.

- Dashed Lines: These often indicate fluid lines (e.g., transmission fluid) or vacuum lines.

- Colors: Colors are often used to differentiate systems (e.g., transmission fluid in red, brake fluid in blue).

- Icons: Specific icons represent different components (e.g., a gear symbol for the transmission, a cylinder symbol for the engine). The legend on the diagram is crucial for understanding these.

Looking at such a diagram helps you visualize the flow of power, track down specific parts, and understand the layout of the system for repair purposes.

How FWD Works: The Power Flow

The basic principle is pretty straightforward:

- The engine generates power through combustion.

- This power is transferred to the transmission.

- The transmission uses gears to multiply torque or increase speed, sending the appropriate power to the differential.

- The differential splits the power and allows each front wheel to rotate at different speeds during turns.

- The axles, equipped with CV joints, transmit this power from the differential to the wheels, making the car move.

This compact arrangement means that weight is concentrated over the front wheels, potentially aiding traction in slippery conditions. However, it also contributes to what's known as torque steer, which is a tendency for the steering wheel to pull to one side under hard acceleration, especially in more powerful FWD vehicles. Torque steer is due to unequal driveshaft lengths and slight variations in wheel slip.

Real-World Use: Basic Troubleshooting Tips

Here are a few common FWD problems and how your understanding of the system can help diagnose them:

- Clicking or Popping Sounds During Turns: This is a classic sign of a failing CV joint. The grease inside the joint has likely dried out or the boot has been torn, allowing dirt and debris to contaminate the joint. A diagram can help you pinpoint which CV joint is making the noise (inner or outer).

- Vibrations at Highway Speeds: This could be due to several things, including imbalanced tires, bent wheels, or worn CV joints. Check your tires first. But if that doesn't work, inspect your axles and CV joints for damage.

- Wheel Spin on Acceleration: This can be normal, especially on slippery surfaces or in high-horsepower FWD cars. However, excessive wheel spin could indicate a worn differential or other drivetrain issues. Consider upgrading to a limited-slip differential (LSD) to improve traction.

By referring to a FWD diagram, you can trace the power flow and isolate potential problem areas more effectively.

Safety Considerations When Working on FWD Systems

Working on any part of your car involves risks, but the FWD system has some specific hazards you need to be aware of:

- Springs: Be cautious when working around the suspension. Compressed coil springs store a tremendous amount of energy and can cause serious injury if released unexpectedly. Always use proper spring compressors when removing or installing suspension components.

- Transmission Fluid: Transmission fluid can be hot and slippery. Always allow the transmission to cool down before draining the fluid. Wear gloves to protect your skin.

- CV Joints: CV joints are packed with grease, which can be messy. Wear gloves and eye protection when handling CV joints.

- Airbags: Before disconnecting any electrical components near the steering wheel or dashboard, disconnect the negative terminal of the battery and wait at least 10 minutes to allow the airbag system to discharge.

Always consult your vehicle's repair manual for specific safety instructions and torque specifications. And when in doubt, it's always best to consult a qualified mechanic.

Hopefully, this overview has given you a better understanding of FWD systems. You're now better equipped to diagnose problems, perform basic maintenance, and even consider performance upgrades. With a little knowledge and the right tools, you can tackle a lot of FWD-related tasks yourself!

For a detailed FWD diagram specific to your vehicle, search online using your car's make, model, and year. Repair manuals will often have the diagram you need.