What Does Fwd Mean In Cars

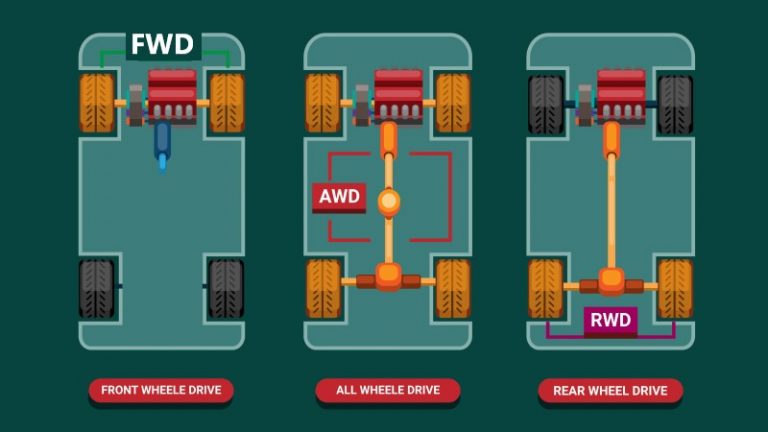

Alright, let's break down what "FWD" or Front-Wheel Drive means in cars. You’ve probably heard the term thrown around, but understanding its intricacies is crucial whether you're tackling repairs, planning modifications, or just expanding your automotive knowledge. This article provides a deep dive into FWD systems, going beyond the basics to equip you with practical knowledge for your DIY projects.

Purpose of Understanding FWD

Why bother learning about FWD? Well, a solid grasp of this drivetrain configuration is invaluable for several reasons:

- Diagnosis and Repair: Identifying problems specific to FWD systems, such as issues with CV axles, transaxles, and differentials, becomes much easier.

- Modification Planning: When considering performance upgrades, you need to understand how FWD affects handling, traction, and power delivery.

- General Automotive Knowledge: Knowing the workings of FWD helps you appreciate the engineering trade-offs involved in different drivetrain layouts.

- Informed Purchasing Decisions: Understanding the pros and cons of FWD can help you choose the right vehicle for your needs.

Key Specs and Main Parts of a FWD System

A Front-Wheel Drive system is characterized by having the engine and transmission packaged together at the front of the vehicle, delivering power exclusively to the front wheels. Here are the key components:

- Engine: The powerplant that generates the mechanical energy. Its placement is almost always transverse (sideways) in FWD vehicles to save space.

- Transmission (or Transaxle): This is the crucial part. In FWD setups, the transmission and differential are often integrated into a single unit called a transaxle. A transaxle performs the functions of both a transmission (changing gear ratios) and a differential (allowing the wheels to spin at different speeds during turns).

- Gear Train: A set of gears that provide different gear ratios for varying speeds and torque requirements.

- Differential: Allows the front wheels to rotate at different speeds when cornering. It uses a series of gears to split the torque while accommodating variations in wheel speed.

- CV Axles (Constant Velocity Axles): These axles transmit power from the transaxle to the front wheels. They are designed with special joints to allow for both suspension travel (up and down movement) and steering (turning the wheels).

- Front Suspension: A crucial part of the system to manage torque-steer issues. Common setups include MacPherson struts or double wishbone designs.

Understanding Symbols in FWD Diagrams

When looking at FWD diagrams, here's what common symbols represent:

- Solid Lines: Typically represent mechanical linkages or power flow paths (e.g., the path of torque from the engine to the transaxle, and then to the CV axles).

- Dashed Lines: Often indicate vacuum lines, fluid lines (e.g., brake lines, power steering lines), or electrical wiring.

- Arrows: Show the direction of fluid flow, power transmission, or movement.

- Circles/Ovals: Commonly represent gears, pulleys, or other rotating components.

- Rectangles/Squares: Can represent electronic control modules, sensors, or switches.

- Color Coding: Varies depending on the diagram, but can differentiate between different systems (e.g., blue for coolant, red for oil, yellow for fuel). Always refer to the diagram's legend.

How a FWD System Works

Let's trace the flow of power in a FWD system:

- The engine generates power, which is then transferred to the transaxle.

- Inside the transaxle, the gear train selects the appropriate gear ratio based on the driver's input (throttle position and gear selection).

- The differential within the transaxle splits the torque between the two front wheels, allowing them to rotate at different speeds when cornering.

- Finally, the CV axles transmit this torque from the transaxle to the front wheels, propelling the vehicle forward.

Real-World Use: Basic Troubleshooting Tips

Here are some common FWD issues and how to approach them:

- Clicking or Popping Noises During Turns: This is a classic sign of worn CV joints. Inspect the CV axle boots for tears or leaks. If the boots are damaged, grease can escape and contaminants can enter, leading to joint failure. Replacement of the CV axle is usually the best solution.

- Vibrations at Certain Speeds: This could be due to unbalanced tires, bent wheels, or damaged CV axles. Start by balancing the tires. If the vibration persists, inspect the wheels and CV axles for damage.

- Torque Steer: This is the tendency of the steering wheel to pull to one side during acceleration, especially in high-powered FWD vehicles. It's an inherent characteristic of FWD, but excessive torque steer can indicate problems with the suspension, tire pressure, or differential.

- Difficulty Shifting: Problems shifting can be caused by low transmission fluid, worn synchronizers, or issues with the shift linkage. Check the transmission fluid level and condition. If the fluid is low or dirty, flush and refill the transmission.

Important Note: When diagnosing transmission problems, be sure to use an OBD-II scanner to check for diagnostic trouble codes (DTCs). These codes can provide valuable clues about the nature of the problem.

Safety Considerations When Working on FWD Systems

Working on a FWD system can be risky if proper safety precautions are not taken:

- Spring Compression: The front suspension components, especially MacPherson struts, contain powerful coil springs that can cause serious injury if mishandled. Always use a spring compressor when disassembling struts. If you are not completely comfortable with this process, take the assembly to a professional.

- Brake System: Be extremely careful when working around the brake system. Brake fluid is corrosive, and the system is under high pressure. Always wear safety glasses and gloves.

- Transaxle Fluid: Transmission fluid can be hot and slippery. Wear gloves and eye protection when handling it.

- Vehicle Support: Never work under a vehicle that is only supported by a jack. Always use jack stands on a level surface.

- Electrical System: Disconnect the negative battery cable before working on any electrical components.

A crucial safety tip: Before starting any work, always consult the vehicle's service manual for specific instructions and torque specifications. Improperly tightened bolts can lead to component failure and potential accidents.

With the right knowledge and tools, you can confidently diagnose and repair many FWD system issues. Remember to prioritize safety and consult the service manual for your specific vehicle. Good luck!

We have a detailed FWD diagram available for download. This diagram provides a visual representation of the system's components and their relationships, further enhancing your understanding. Contact us for access.