What Does The 4x4 On A Truck Mean

Alright, let's dive into the world of 4x4 systems on trucks. For those of you who are already comfortable getting your hands dirty under the hood, this breakdown will serve as a comprehensive guide to understanding what that "4x4" badge truly means and how the whole system operates. Whether you're planning modifications, troubleshooting a problem, or just want a deeper understanding of your vehicle, this knowledge is invaluable.

Purpose of Understanding 4x4 Systems

Understanding the intricacies of your truck's 4x4 system is crucial for several reasons. First and foremost, it allows for effective troubleshooting. A symptom like wheel slippage or inability to engage four-wheel drive can be pinpointed more accurately when you know the system's components and their functions. Secondly, it empowers you to perform basic maintenance and repairs, potentially saving significant money on shop fees. Finally, for those of you who enjoy modifying your trucks, understanding the limitations and capabilities of the 4x4 system is essential for making informed decisions about upgrades like lift kits, tire sizes, and differential modifications.

Key Specs and Main Parts

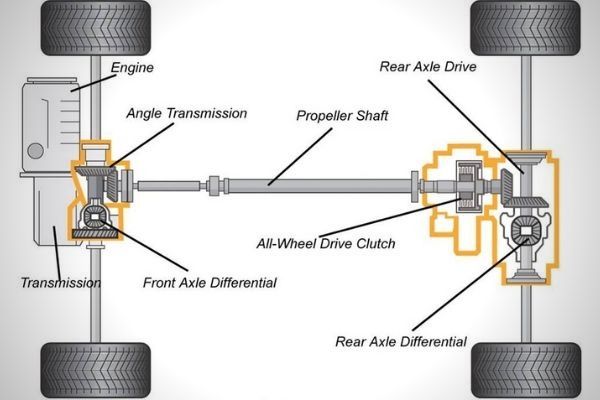

The "4x4" designation, or sometimes "4WD" (Four-Wheel Drive), essentially means that the vehicle has the capability to deliver power to all four wheels. This significantly improves traction, especially in off-road conditions, snow, or other low-grip surfaces. To achieve this, several key components work in concert:

- Engine: The source of power, as always.

- Transmission: Transfers engine power and torque to the drivetrain.

- Transfer Case: This is the heart of the 4x4 system. It splits the power from the transmission and sends it to both the front and rear axles. Different types exist, including part-time, full-time, and automatic transfer cases.

- Front and Rear Driveshafts: These rotating shafts transmit power from the transfer case to the front and rear differentials.

- Front and Rear Differentials: Differentials allow each wheel on an axle to rotate at different speeds, which is crucial when turning. They also split the torque delivered by the driveshaft between the wheels on that axle.

- Axle Shafts: These shafts connect the differential to the wheels.

- Locking Hubs (on some older systems): Manually or automatically lock the front wheels to the front axles, enabling 4x4 engagement. Newer systems often use integrated axle disconnect systems.

- Electronic Controls (on modern systems): A network of sensors and actuators controlled by a computer module. These can automate engagement and disengagement of 4x4, control traction control, and manage electronic locking differentials.

When discussing specs, a critical one is the gear ratio of the transfer case, particularly the low-range ratio. This ratio multiplies the torque output of the engine, providing significantly more power at lower speeds – essential for crawling over obstacles. For example, a low-range ratio of 2.72:1 means that for every one rotation of the transfer case input shaft, the output shaft rotates 2.72 times *slower*, resulting in 2.72 times *more* torque.

How It Works

The basic principle is simple: the engine's power goes through the transmission to the transfer case. The transfer case then splits this power, sending it to both the front and rear axles via the driveshafts. The differentials at each axle then distribute the power to the wheels. However, the details get more complex depending on the type of 4x4 system.

Part-Time 4x4: This is the most common type. In normal driving conditions, only the rear wheels receive power (2WD). When 4x4 is engaged, the transfer case mechanically locks the front and rear driveshafts together, forcing them to rotate at the same speed. This is great for off-road use, but should not be used on pavement because it can cause binding and damage to the drivetrain. This binding occurs because, when turning on pavement, the front wheels travel a longer distance than the rear wheels. A locked transfer case prevents the necessary speed difference, leading to stress on the system.

Full-Time 4x4: This system constantly sends power to all four wheels. It uses a center differential (or a viscous coupling) in the transfer case to allow for some speed difference between the front and rear axles. This makes it suitable for on-road use in slippery conditions, as it can distribute power as needed without causing binding. However, full-time systems often aren't as robust for extreme off-roading as part-time systems with a locked transfer case.

Automatic 4x4: These systems use sensors and a computer to automatically engage 4x4 when wheel slippage is detected. They are often a hybrid of part-time and full-time systems, using a clutch or viscous coupling in the transfer case to engage the front axle as needed. This provides the convenience of automatic engagement but may not offer the same level of control as a manually engaged system.

Electronic Locking Differentials: Many modern 4x4 systems also include electronic locking differentials, often abbreviated as "e-lockers." These differentials can be electronically locked, forcing both wheels on an axle to rotate at the same speed. This is extremely useful in situations where one wheel loses traction, as it prevents all the power from being sent to the spinning wheel. Engaging an e-locker effectively creates a solid axle.

Real-World Use – Basic Troubleshooting Tips

Here are some common 4x4 issues and potential causes:

- Difficulty Engaging 4x4: Check vacuum lines (on older systems), electric actuators, and the transfer case shift motor. A common issue is a worn-out shift motor that can't fully engage the gears in the transfer case.

- Clunking or Grinding Noises: This could indicate a problem with the transfer case, differentials, or driveshafts. Inspect universal joints (U-joints) on the driveshafts for wear or damage. Low fluid levels in the transfer case or differentials can also cause noises.

- Vibrations in 4x4: This is often caused by unbalanced tires, worn U-joints, or a bent driveshaft.

- 4x4 Engages But No Power to Front Wheels: Check the front axle disconnect system (if equipped) and the front differential.

Remember to always consult your vehicle's owner's manual for specific instructions on engaging and disengaging 4x4, as well as recommended maintenance schedules.

Safety – Highlight Risky Components

Working on the 4x4 system involves dealing with heavy components and potentially dangerous rotating parts. Always disconnect the battery before working on any electrical components. When working underneath the vehicle, use jack stands to support the weight of the vehicle safely. Never rely solely on a jack. Be extremely cautious when working near rotating parts like driveshafts and axles, and ensure the vehicle is in park and the parking brake is engaged. When dealing with differentials, be aware of the potential for gear oil to be hot. Allow the system to cool down before attempting to drain or service it.

Specifically, the following components pose higher risks:

- Driveshafts: Can cause serious injury if they spin unexpectedly.

- Differentials: Contain heavy gears and potentially hazardous fluids.

- Transfer Case: Complex mechanism that can be damaged if not handled carefully.

- Electronic Actuators: Can cause electrical shock if not disconnected properly.

By understanding the components, operation, and potential issues of your truck's 4x4 system, you're well-equipped to tackle maintenance, repairs, and even modifications with confidence. Always prioritize safety, and don't hesitate to consult a qualified mechanic if you're unsure about any aspect of the system.

Now that you've got a better handle on the theory behind it, visualizing the system can be really helpful. We have a detailed schematic diagram of a typical 4x4 system that visually represents all the components and their connections. This diagram can be a valuable tool for understanding the flow of power and for troubleshooting issues. You can download the diagram to have it readily available for your projects and maintenance tasks.