What Does The Car Transmission Do

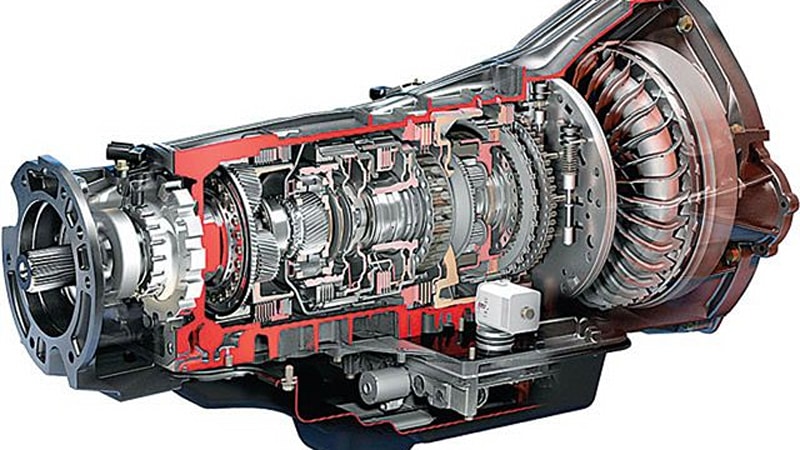

Understanding your car's transmission is crucial for any serious DIY mechanic or car enthusiast. Whether you're planning repairs, modifications, or simply want a deeper understanding of how your vehicle works, knowing the ins and outs of the transmission is essential. This article will break down the complexities of the transmission system, focusing on its purpose, key components, and operational principles, equipping you with the knowledge to diagnose common issues and perform basic maintenance. We even have a detailed diagram of a typical automatic transmission available for download (link provided at the end of this article).

Key Specs and Main Parts

The transmission's primary function is to transfer power from the engine to the wheels while providing a variety of gear ratios to optimize engine speed (RPM) and torque. This allows the engine to operate efficiently at different vehicle speeds and loads.

Here's a breakdown of the core components you'll find in a typical automatic transmission:

- Torque Converter: Replaces the clutch in a manual transmission. It uses fluid coupling to transfer engine torque to the transmission input shaft. It also provides torque multiplication, especially at low speeds.

- Planetary Gear Sets: These are the heart of the automatic transmission. They consist of sun gears, planet gears, a ring gear, and a carrier. By engaging different combinations of these gears, the transmission achieves various gear ratios.

- Valve Body: The hydraulic control center of the transmission. It contains a complex network of valves, channels, and solenoids that direct fluid pressure to engage and disengage the clutches and bands that control the planetary gear sets.

- Clutches and Bands: These friction elements engage and disengage different parts of the planetary gear sets, locking them together or allowing them to spin freely, thereby changing the gear ratio. Clutches are multi-plate friction discs that are compressed together. Bands are metal straps that wrap around the outside of a drum and are tightened to stop it from rotating.

- Transmission Fluid (ATF): Acts as a hydraulic fluid to operate the valve body, lubricate moving parts, and cool the transmission. Proper ATF level and condition are critical for transmission health.

- Transmission Control Module (TCM): A computer that monitors various sensors (engine speed, vehicle speed, throttle position, etc.) and controls the solenoids in the valve body to shift gears automatically.

Manual transmissions, on the other hand, are mechanically simpler and generally more reliable. Key components include:

- Clutch: Mechanically connects and disconnects the engine from the transmission, allowing for gear changes. Consists of a friction disc, pressure plate, and throwout bearing.

- Gears: Mesh together to provide different gear ratios. Typically arranged in pairs on shafts.

- Shift Forks and Rails: Move the gears along the shafts to engage different gear combinations.

- Synchronizers: Help to match the speed of the gears before they engage, resulting in smoother shifting.

How It Works (Automatic Transmission)

The torque converter acts as a fluid coupling, allowing the engine to run even when the vehicle is stopped. As the engine speed increases, the torque converter transmits more power to the transmission. Inside the transmission, the TCM receives information from various sensors. Based on this data, the TCM determines the optimal gear ratio for the current driving conditions. The TCM then signals the solenoids in the valve body to direct fluid pressure to the appropriate clutches and bands. These clutches and bands engage and disengage, locking and unlocking different parts of the planetary gear sets, thereby changing the gear ratio.

For example, to shift from first gear to second gear, the TCM might activate a solenoid that directs fluid pressure to disengage one clutch and engage another. This changes the configuration of the planetary gear sets, resulting in a different gear ratio that provides more speed and less torque. The process is repeated for each subsequent gear change, allowing the vehicle to accelerate smoothly and efficiently.

How It Works (Manual Transmission)

The driver controls gear selection using the shift lever. When the clutch pedal is pressed, it disengages the clutch, disconnecting the engine from the transmission. The driver then moves the shift lever to select the desired gear. This action moves the shift forks, which in turn move the gears along the shafts. The synchronizers help to mesh the gears smoothly. Once the gear is engaged, the driver slowly releases the clutch pedal, re-engaging the engine and transmitting power to the wheels through the selected gear ratio.

Symbols – Lines, Colors, and Icons (Diagram)

Diagrams of transmission systems utilize specific symbols to represent different components and functions. Understanding these symbols is crucial for interpreting the diagrams effectively. While the specific symbols may vary slightly depending on the diagram's source and purpose, some common conventions include:

- Solid Lines: Typically represent mechanical linkages or connections. In a hydraulic diagram, a solid line often represents a high-pressure fluid line.

- Dashed Lines: Often indicate control signals (electrical or vacuum) or lower pressure fluid lines.

- Colors: Colors may be used to differentiate between different types of fluid (e.g., red for high-pressure fluid, blue for low-pressure fluid). Electrical wiring diagrams use color coding extensively to identify different circuits and wire functions.

- Circles: May represent hydraulic accumulators or other fluid reservoirs.

- Squares/Rectangles: Commonly used to represent valve bodies, solenoids, or other control components. Internal features like springs or orifices are often drawn within the square.

- Gears: Clearly represent gears, often with the number of teeth indicated.

- Clutch Packs: Shown as stacked discs, indicating the friction surfaces.

Understanding these conventions allows you to trace the flow of power and control signals through the transmission system, making it easier to diagnose problems and perform repairs.

Real-World Use – Basic Troubleshooting Tips

Here are some common transmission problems and troubleshooting tips:

- Slipping Gears: Engine RPMs increase without a corresponding increase in vehicle speed. This can be caused by worn clutches or bands, low transmission fluid, or a malfunctioning valve body. Check the fluid level and condition first. If the fluid is dark, burnt, or has a metallic smell, it's likely time for a transmission service or rebuild.

- Rough Shifting: Harsh or jerky gear changes. This can be caused by worn synchronizers (in manual transmissions), a malfunctioning valve body (in automatic transmissions), or incorrect transmission fluid.

- Delayed Engagement: A noticeable delay between selecting a gear and the vehicle moving. This can be caused by low transmission fluid, a worn torque converter, or internal transmission damage.

- Fluid Leaks: Check for leaks around the transmission pan, seals, and lines. Leaks can lead to low fluid levels and transmission damage. Address leaks promptly.

- Unusual Noises: Whining, grinding, or clunking noises coming from the transmission area. These noises can indicate worn bearings, damaged gears, or other internal problems.

Note: Always consult your vehicle's service manual for specific troubleshooting procedures and diagnostic codes.

Safety – Highlight Risky Components

Working on transmissions can be dangerous. Here are some key safety considerations:

- High Temperatures: Transmission fluid can get extremely hot. Allow the transmission to cool down completely before working on it.

- Springs and Pressurized Components: The valve body contains numerous springs and pressurized components that can cause injury if mishandled. Exercise extreme caution when disassembling the valve body. Wear safety glasses.

- Heavy Components: Transmissions are heavy. Use proper lifting equipment (e.g., a transmission jack) to support the transmission during removal and installation. Never attempt to lift a transmission by hand.

- Electrical Hazards: Disconnect the battery before working on any electrical components of the transmission, such as the TCM or solenoids.

- Proper Support: Always use jack stands to support the vehicle before working underneath it.

Disposing of used transmission fluid properly is essential. Contact your local auto parts store or recycling center for information on proper disposal methods.

By understanding the principles of operation and safety precautions, you can confidently tackle basic transmission repairs and maintenance tasks. Remember to always consult your vehicle's service manual for specific procedures and specifications. A detailed diagram can be a powerful tool, providing a visual representation of the system and aiding in diagnosis and repair. You can download a sample automatic transmission diagram HERE (example link). Good luck!